A kind of carboxymethyl lactose and its preparation method and application

A technology of carboxymethyl lactose and lactose, which is applied in the field of daily chemicals, can solve the problems that hyaluronic acid cannot meet market needs, and achieve the effects of improving moisture absorption and moisturizing performance, reducing production costs, and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Carboxymethyl lactose is a compound shown in formula one.

[0026] Preparation of carboxymethyl lactose: Add 1.8g of lactose (see Formula 1) to 20mL of isopropanol and stir to swell at room temperature for 30min, then add 6ml of 10mol / L sodium hydroxide solution, stir and react at 40°C for 3h, then add chlorine 1.8g of acetic acid was reacted at 60°C for 12h. After the reaction, it was neutralized with acetic acid to neutrality, then precipitated with methanol, filtered with suction, washed with 50mL of methanol and 50mL of ethanol for 3 times, filtered with suction, and vacuum freeze-dried to obtain Pale yellow product carboxymethyl lactose (see figure 2 ). Carboxymethyl lactose is light yellow powder or solid, easily soluble in cold and boiling water without being pasty, transparent liquid, slightly soluble in ethanol.

[0027] Wherein lactose (lactose) is 4-O-β-D-galactopyranosyl-D-glucose.

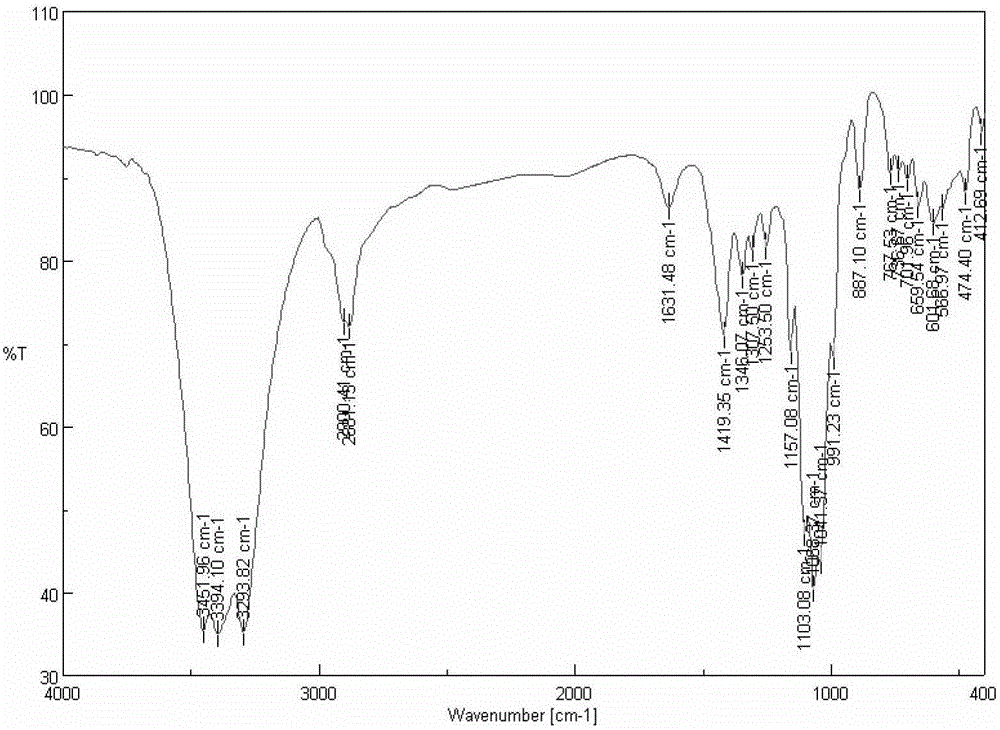

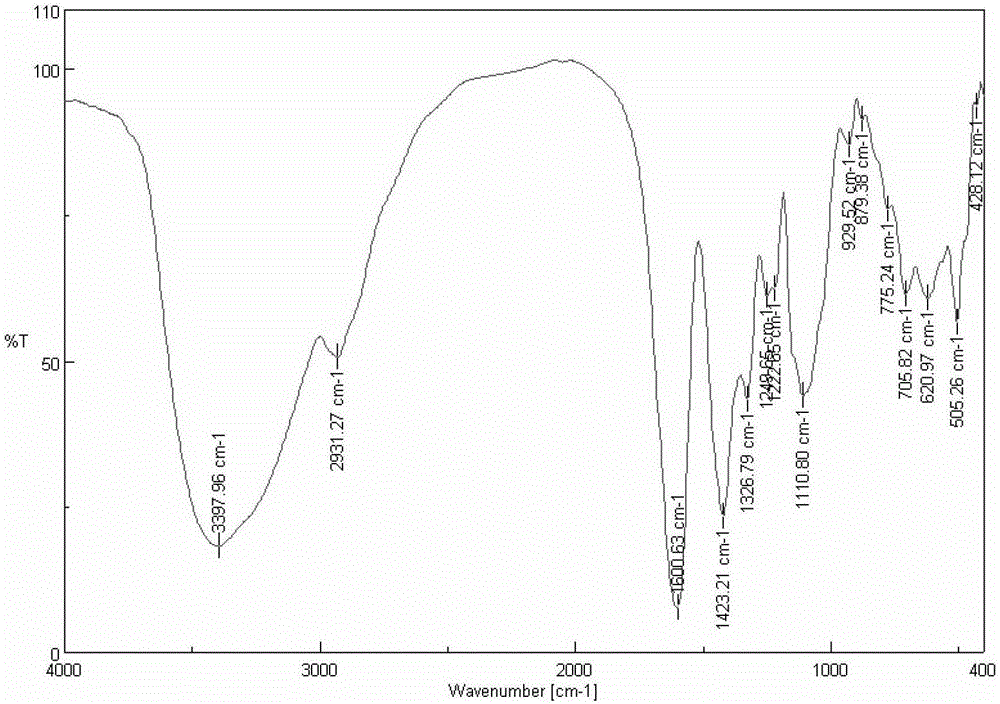

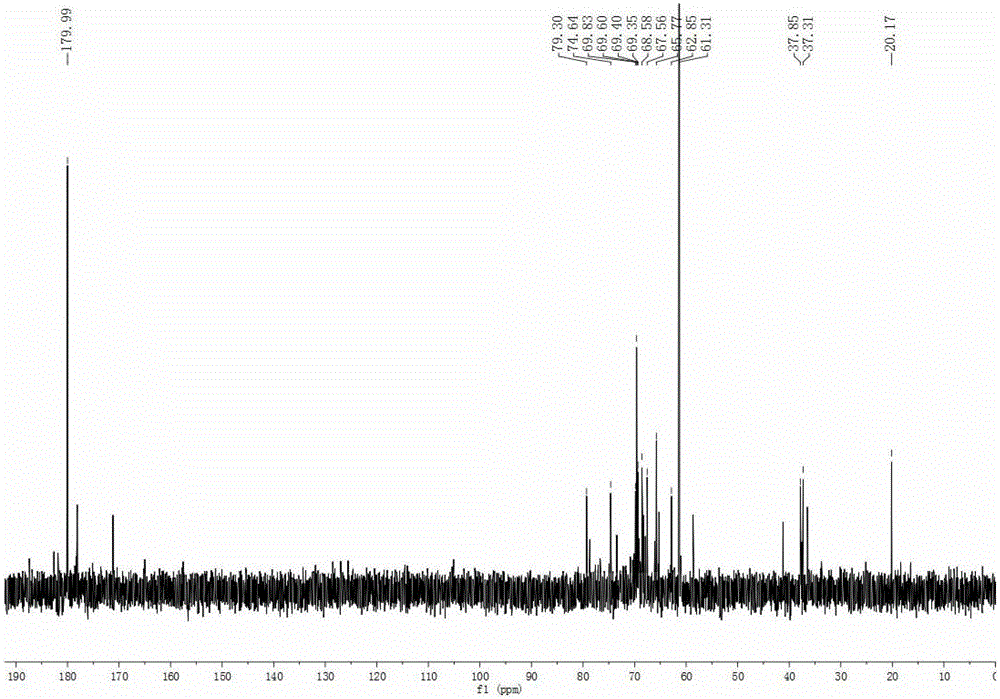

[0028] From figure 2 It can be seen that compared with lactose raw ma...

Embodiment 2

[0030] The difference from Example 1 is:

[0031] Add 1.8g of lactose to 20mL of isopropanol, stir and swell at room temperature for 60min, then add 6ml of 10mol / L sodium hydroxide solution, stir and react at 40°C for 3h, then add 1.8g of chloroacetic acid and react at 50°C for 16h, in acetic acid After being neutralized, it was precipitated with methanol, filtered with suction, washed with 50 mL of methanol and 50 mL of ethanol in sequence, filtered with suction, and vacuum freeze-dried to obtain carboxymethyl lactose.

Embodiment 3

[0033] The difference from Example 1 is: add 1.8g of lactose to 20mL of isopropanol, stir and swell at room temperature for 30min, then add 6ml of 10mol / L sodium hydroxide solution, stir and react at 40°C for 6h, and then add 1.8g of chloroacetic acid Reacted at 60°C for 16 hours, neutralized to neutral with acetic acid, precipitated with methanol, filtered with suction, washed with 50mL of methanol and 50mL of ethanol in turn, filtered with suction, and vacuum freeze-dried to obtain carboxymethyllactose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com