Moisture absorption humectant employing trehalose quaternary ammonium salt and preparation thereof

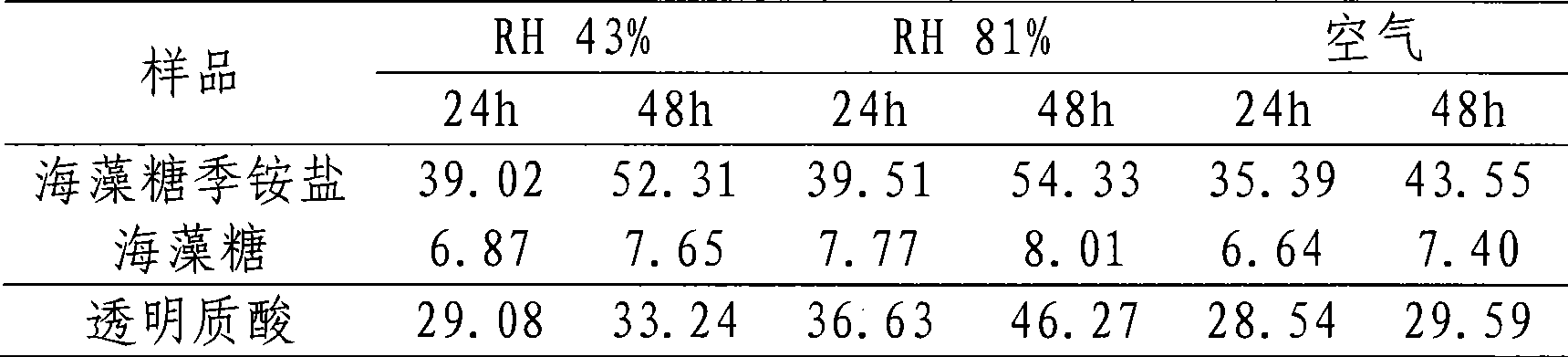

A technology of trehalose and quaternary ammonium salt, applied in the field of daily chemicals, can solve the problems of high extraction cost, trehalose cannot meet market needs, cannot be chemically synthesized, etc., and achieves the effects of high hygroscopic and moisturizing performance, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

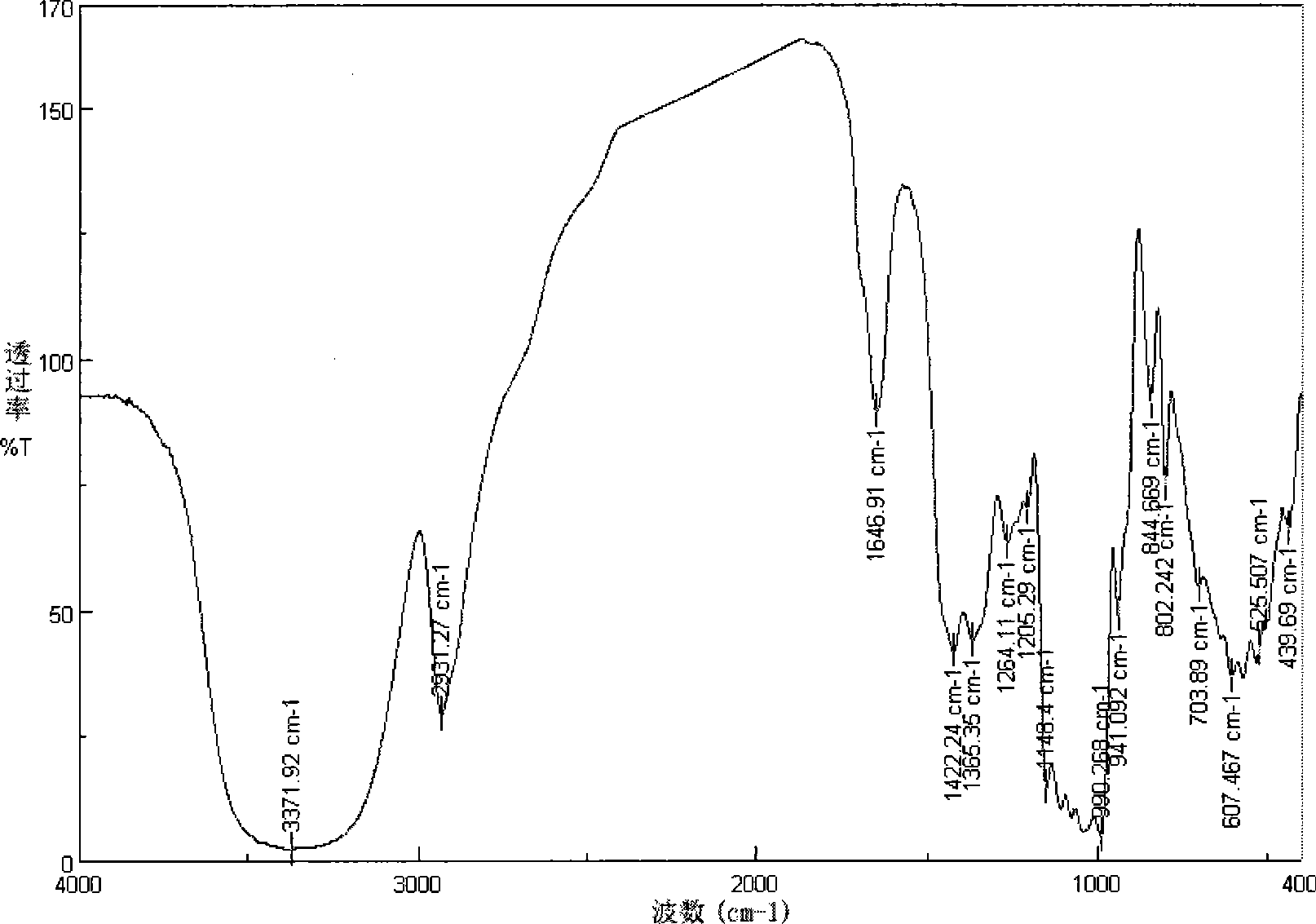

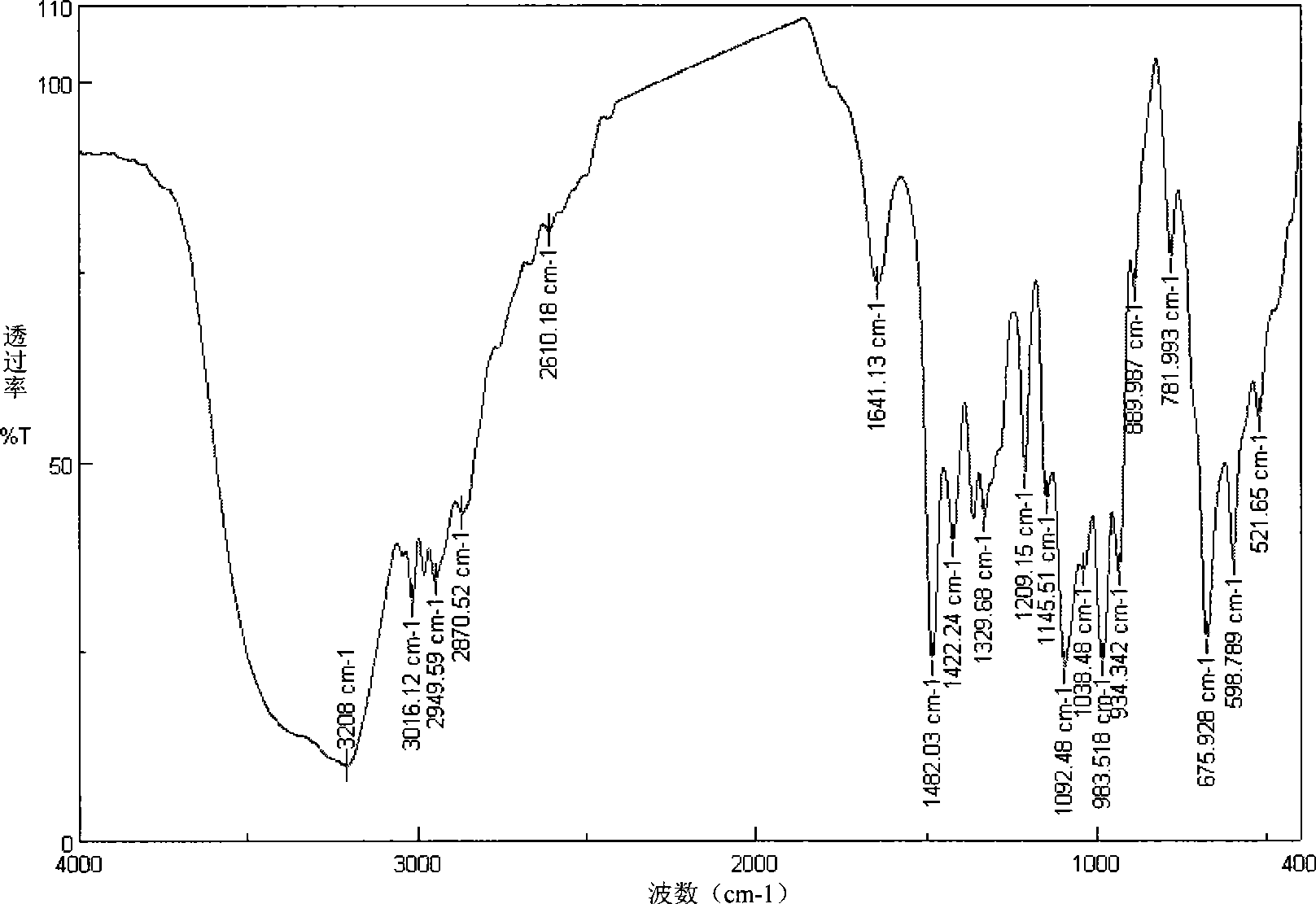

[0015] Preparation of trehalose quaternary ammonium salt: 1g trehalose (see figure 1 ) was added 10mL isopropanol, then 0.25g NaCl (5%) was added to prevent swelling, the pH was adjusted to 11 with NaOH, and the etherifying agent 2,3-epoxypropyltrimethylammonium chloride (25%, MW =188.1) 7.96mL, stirred and reacted in a water bath at 40°C for 7-9h, neutralized with acetic acid or hydrochloric acid to a pH of 6.0-7.0, washed with an appropriate amount of methanol, suction filtered, and dried at 50°C to obtain trehalose quaternary ammonium salt ( see figure 2 ).

[0016] From figure 2 It can be seen that compared with trehalose, 1482cm -1 and 3016cm -1 The absorption peak at place is the characteristic absorption peak of quaternary ammonium group (Liu Zemin, Zhang Yuqing, Wang Jinggang, Hu Junjun; Synthesis of 2,3-epoxypropyltrimethylammonium chloride by phase transfer autocatalysis; Journal of Henan University of Science and Technology, Natural Science Edition, 2006, 27:...

Embodiment 2

[0019] The difference from Example 1 is:

[0020] Preparation of trehalose quaternary ammonium salt: add 1g trehalose to 12.5mL isopropanol, then add 0.3g NaCl (5%) to prevent swelling, adjust pH=11 with NaOH, add etherifying agent 2,3-epoxypropyl Trimethylammonium chloride (25%) 9.95mL, stirred and reacted in a water bath at 50°C for 5-7h, neutralized with acetic acid or hydrochloric acid to a pH of 6.0-7.0, washed with an appropriate amount of methanol, suction filtered, and dried at 50°C. Trehalose quaternary ammonium salt was obtained.

Embodiment 3

[0022] The difference from Example 1 is:

[0023] Preparation of trehalose quaternary ammonium salt: add 1g trehalose to 15mL isopropanol, then add 0.35g NaCl (5%) to prevent swelling, adjust pH=11 with NaOH, add etherification agent 2,3-epoxypropyl trimethyl ammonium chloride (25%) 11.94mL, stirred and reacted in a water bath at 60°C for 3-5h, neutralized with acetic acid or hydrochloric acid to a pH of 6.0-7.0, washed with an appropriate amount of methanol, suction filtered, and dried at 50°C to obtain seaweed Sugar quaternary ammonium salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com