A kind of preparation method of fabric finishing agent based on modified silk fibroin solution

A silk fibroin and post-finishing technology, which is applied in the direction of improved hand-feeling fiber, fiber treatment, wear-resistant fiber, etc., can solve the problems of poor mechanical properties of silk fibroin film, high dissolution rate in water, and reduced imitation silk property , to achieve the effects of enhanced toughness, strong moisture absorption and excellent gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

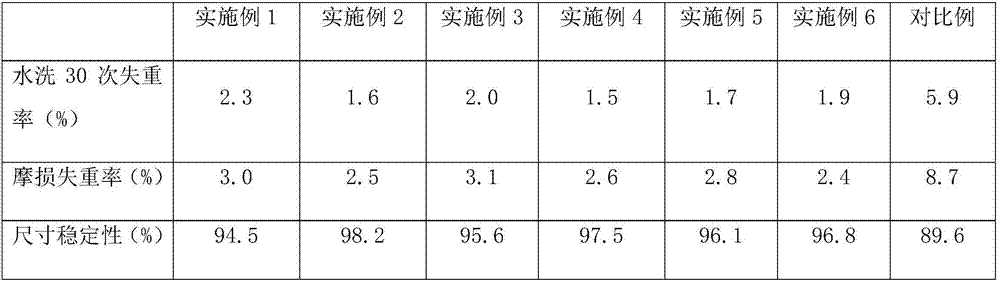

Examples

Embodiment 1

[0029] (1) Remove impurities from the waste silk, put it in 5g / L sodium bicarbonate solution, boil and degumming at 95°C for 60min, remove and wring out, wash with water until there is no greasy feeling, then put it in 2g / L sodium bicarbonate In the solution, boil at 95°C for 60 minutes for degumming, remove and wring out, wash with water until there is no greasy feeling, and then place it in an oven at 60°C to dry to obtain degummed silk.

[0030] (2) Place the degummed silk of 1 part by weight prepared in step (1) in 8 parts of lithium bromide solution, let it stand for dissolving at 60° C. for 30 min, take it out for cooling, dialyze and concentrate to obtain a silk fibroin solution with a mass fraction of 8%. , wherein the molecular weight of silk fibroin is 125KDa.

[0031] (3) Add glycerin and gelatin to the silk fibroin solution prepared in step (2), stir evenly to form a film liquid, adjust the pH value to 6, then add glutaraldehyde and chitosan, stir evenly, and final...

Embodiment 2

[0033] (1) Remove impurities from the waste silk, put it in 8g / L sodium bicarbonate solution, boil and degumming at 98°C for 90 minutes, remove and wring out, wash with water until there is no greasy feeling, and then put it in 3g / L sodium bicarbonate In the solution, boil at 98°C for 90 minutes for degumming, remove and wring out, wash with water until there is no greasy feeling, and then place it in an oven at 60°C to dry to obtain degummed silk.

[0034] (2) Place the degummed silk of 1 part by weight prepared in step (1) in 10 parts of lithium bromide solution, let it stand for dissolving at 80°C for 60 min, take it out for cooling, dialyze and concentrate to obtain a silk fibroin solution with a mass fraction of 6%. , wherein the molecular weight of silk fibroin is 80KDa.

[0035] (3) Glycerin and gelatin are added to the silk fibroin solution prepared in step (2), stirred evenly to form a film solution, and the pH value is adjusted to 7, then glutaraldehyde and chitosan ...

Embodiment 3

[0037] (1) Remove impurities from the waste silk, put it in 6g / L sodium bicarbonate solution, boil it at 97°C for 80 minutes, remove it and wring it out, wash it with water until there is no greasy feeling, and then put it in 2.5g / L hydrogen carbonate solution In sodium solution, boil at 96°C for 70 minutes for degumming, remove and wring out, wash with water until there is no greasy feeling, and then place in an oven at 60°C to dry to obtain degummed silk.

[0038](2) Place the degummed silk of 1 part by weight prepared in step (1) in 9 parts of lithium bromide solution, let it stand and dissolve for 50 min at 70° C., take out and cool, dialyze and concentrate to obtain a silk fibroin solution with a mass fraction of 7%. , wherein the molecular weight of silk fibroin is 105KDa.

[0039] (3) Glycerin and gelatin are added to the silk fibroin solution prepared in step (2), stirred evenly to form a film solution, and the pH value is adjusted to 6.5, then glutaraldehyde and chito...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com