Screw damper and floating slab track system and jacking device and method thereof

A technology of shock absorbers and floating slabs, applied in the direction of tracks, roads, lifting devices, etc., can solve the problems that the shock absorber floating slab rail system cannot meet the construction terrain, the height cannot be continuously adjusted, and the construction progress is delayed, etc., to achieve Easy adjustment/maintenance, uniform overall force, and improved bending stiffness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0073] The present invention mainly provides a floating plate track system which can steplessly adjust the height of the top support of the shock absorber through threads.

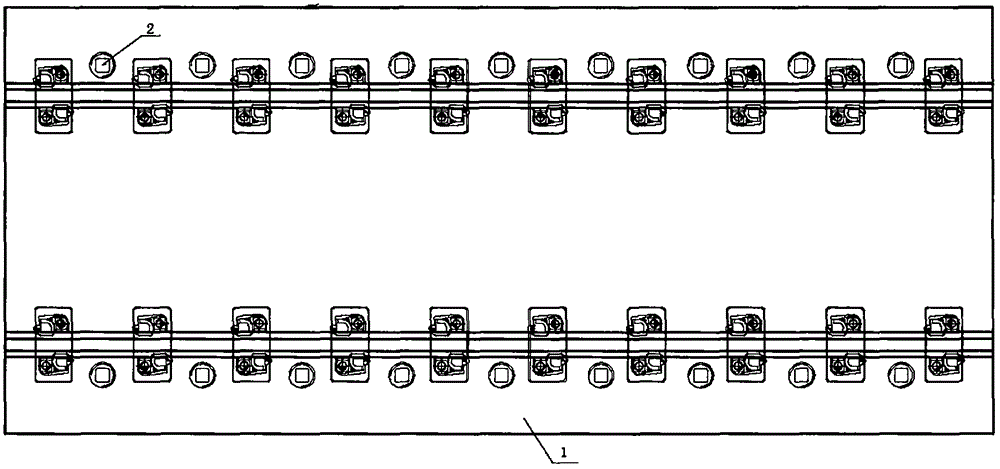

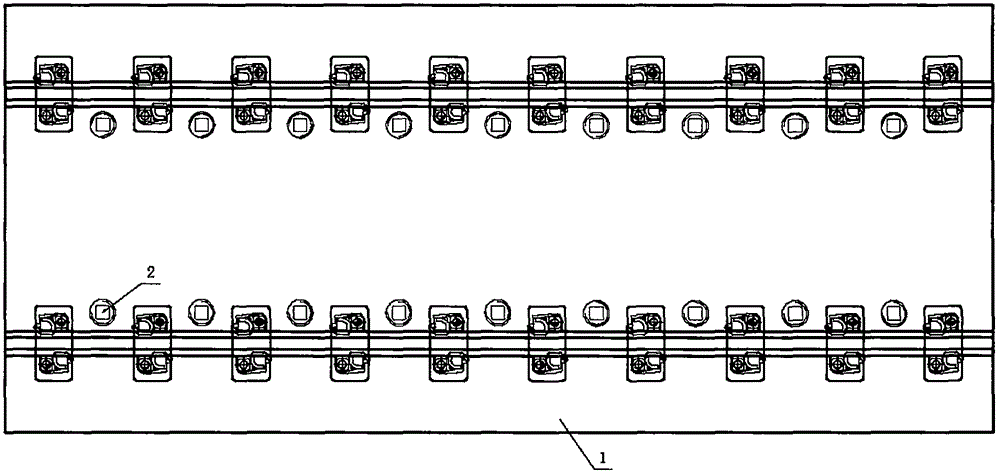

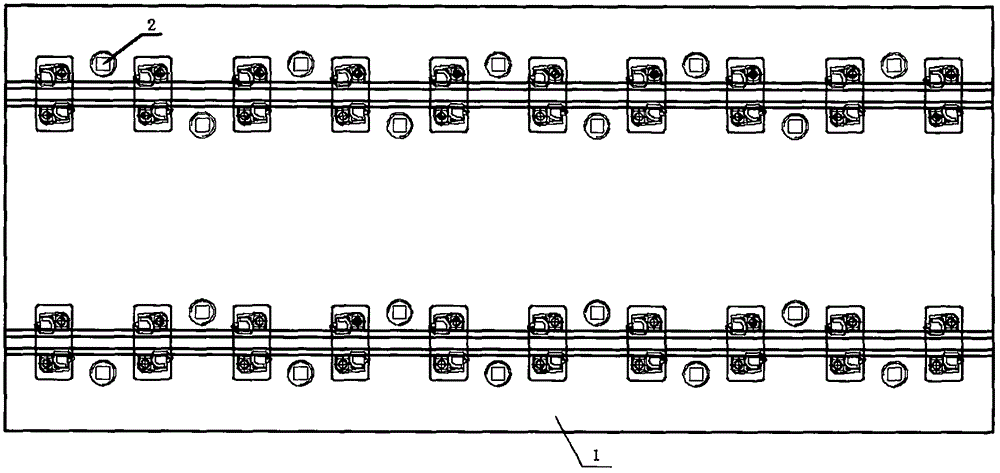

[0074] see figure 1 , the screw damper floating slab track system of the first embodiment of the present invention, it comprises a floating track slab 1 and several screw dampers 2 supporting the floating track slab 1, and each screw damper 2 is evenly distributed on the track outside.

[0075] Wherein, the screw damper 2 includes (combined with Figure 8 and Figure 9 ):

[0076] threaded collar 21, which supports the floating track plate 1, which has internal threads;

[0077] Elastic inner cylinder, it is located at foundation 4 (referring to Figure 11 ), which has an elastic part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com