Method for using box formwork as tire formwork for support beam systems with uneven bottom

A technology for supporting beams and box molds, which is applied in excavation, construction, infrastructure engineering, etc., can solve the problems of time-consuming, labor-intensive, and difficult soil repair, and achieve the effects of simple and convenient production, cost-saving, and low-cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

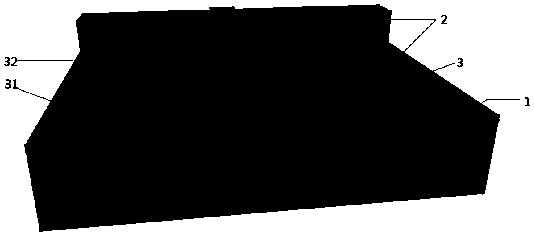

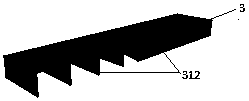

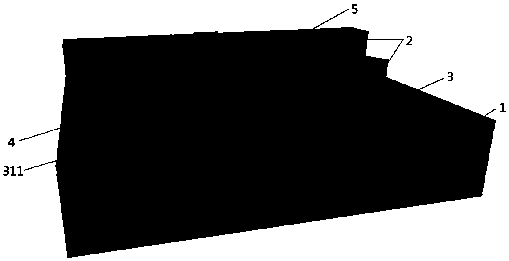

[0021] Such as Figures 1 to 4 As shown, it is embodiment 1 of the method that the mold of the present invention is used as the tire mold of the uneven bottom support beam system, including a common template 31 and a support beam with a large height difference, a slab bottom box mold 3 and a slab bottom support frame 4. The box mold 3 is assembled to form a box-shaped cavity by templates 31, and its longitudinal template is reinforced with a small template 312. The support frame 4 is formed by connecting the vertical square timber 41 and the horizontal square timber 42. The described The spacing between longitudinal square timbers 41 should not be greater than 1.5m. If the plate thickness is large, the spacing between longitudinal square timbers 41 should be properly reduced.

[0022] In this implementation case, the earthwork is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com