Pressurization main machine coaxial driving feed water pump system comprising pure condensing steam extraction small steam turbine

A technology of coaxial drive and water supply pump, which is applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of high investment, low return on investment, and unfeasible economic aspects of the overall renovation project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

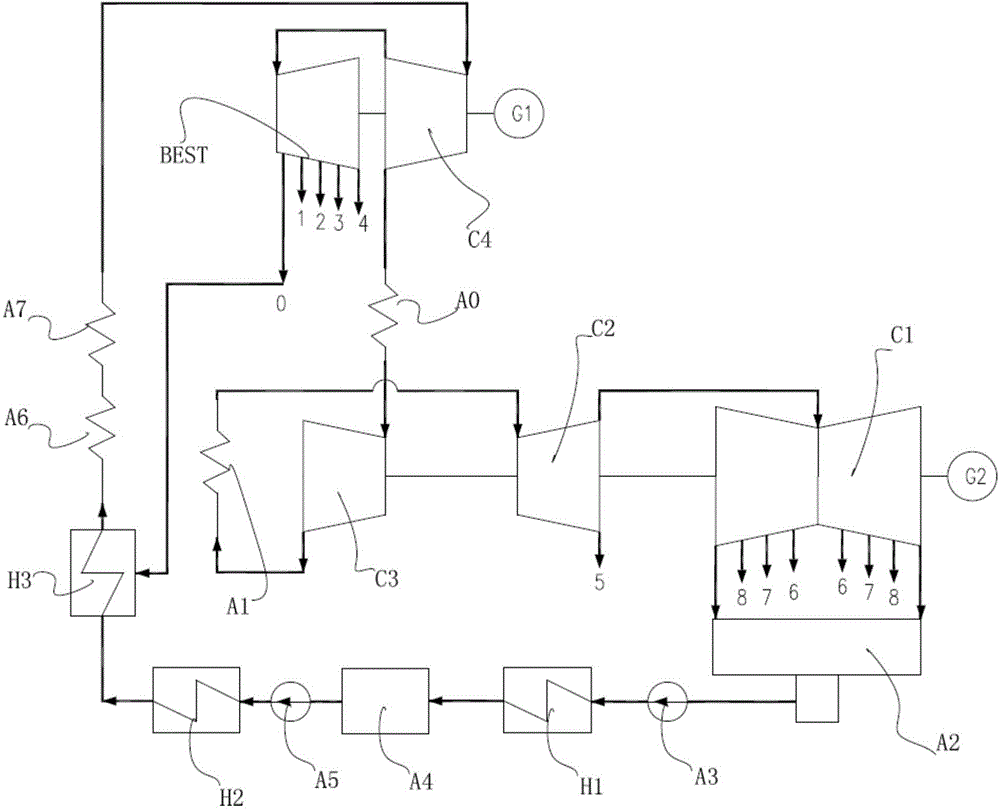

[0081] image 3 It is a structural diagram of a supercharged main engine coaxially driven feed water pump system including a small pure condensing steam extraction machine in Embodiment 1 of the present invention.

[0082] and figure 2 Compared with the supercharged steam turbine thermal system with the shown back pressure extraction cylinder, the present invention adds a second back pressure extraction cylinder (BEST-2) and a second condenser which are not available in the prior art, as shown in the figure , the supercharged main engine coaxially driven feed water pump system containing a small pure condensate extraction machine has a first reheater, a second reheater, a first condenser, a second condenser, a condensate pump, and a deaerator , superheater, economizer, feed water main pump, feed water front pump, speed control gearbox, first generator, second generator, first back pressure extraction cylinder (BEST-1), second back pressure extraction Steam cylinder (BEST-2)...

Embodiment 2

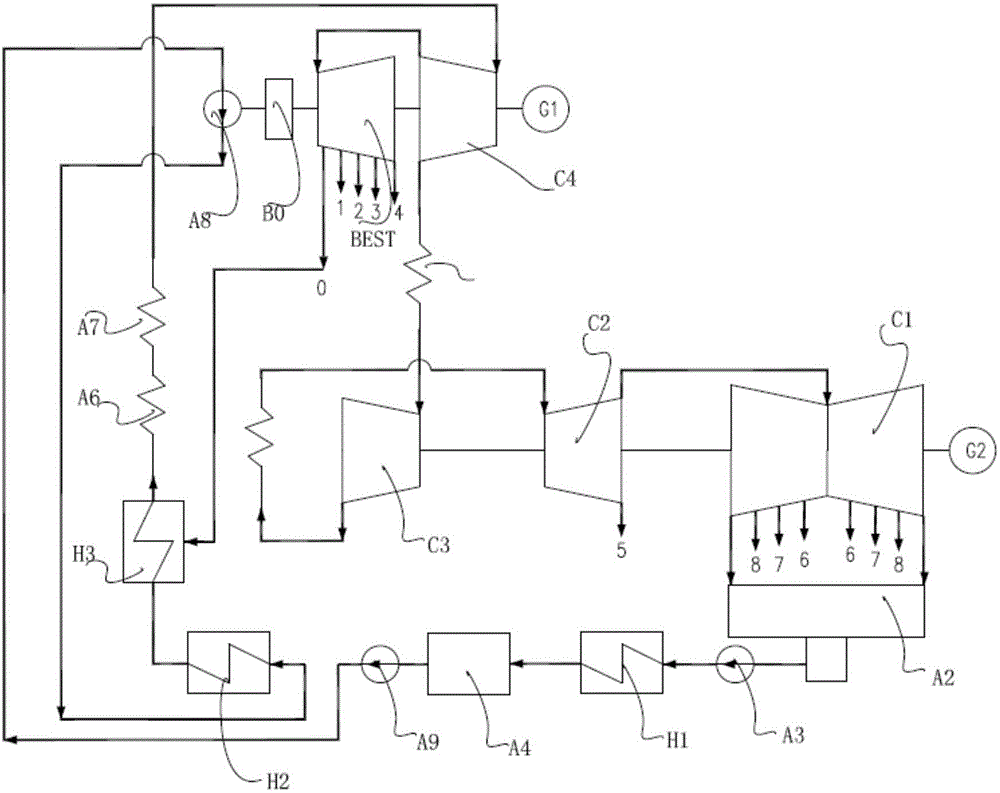

[0092] Figure 4 It is a structural diagram of a supercharged main engine coaxially driven feed water pump system including a small pure condensing steam extraction machine in Embodiment 2 of the present invention.

[0093] Embodiment 2 of the present invention is similar to Embodiment 1, the difference is that the steam extraction of the second high-pressure heater is connected from the steam extraction of the first back pressure extraction cylinder, and the throughflow of the ultra-high pressure cylinder and the first back pressure extraction cylinder As the capacity increases, the output of the first generator increases accordingly.

[0094] The technical solution of embodiment 2 can reduce the coal consumption for power supply ≥ 30g / kW.h.

Embodiment 3

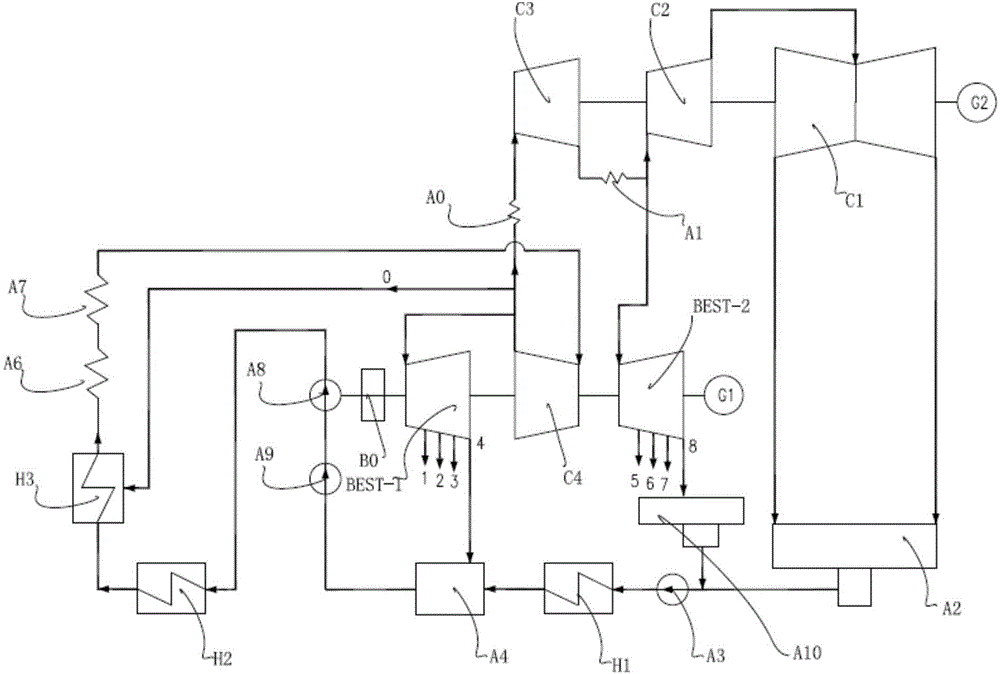

[0096] Figure 5 It is a structural diagram of a supercharged main engine coaxially driven feed water pump system including a small pure condensing steam extraction machine in embodiment 3 of the present invention.

[0097] Embodiment 3 of the present invention is similar to Embodiment 2, the difference is that: the second back pressure extraction cylinder is no longer coaxially arranged with the ultra-high pressure cylinder, the first back pressure extraction cylinder, the first generator, and the feed water pump, and can be arranged according to Engineering needs, individually arranged, increased flexibility. A third generator is added to the second back pressure extraction cylinder, and the excess power can be generated through the third generator.

[0098] The technical solution of embodiment 3 can reduce the coal consumption for power supply ≥ 30g / kW.h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com