Gas injectors with thermally protected elastomer sealing elements

A gas injector and sealing element technology, which is applied to engine components, fuel injection devices, special fuel injection devices, etc., can solve the problems of high temperature stability and easy wear, and achieve the effect of simplified design and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

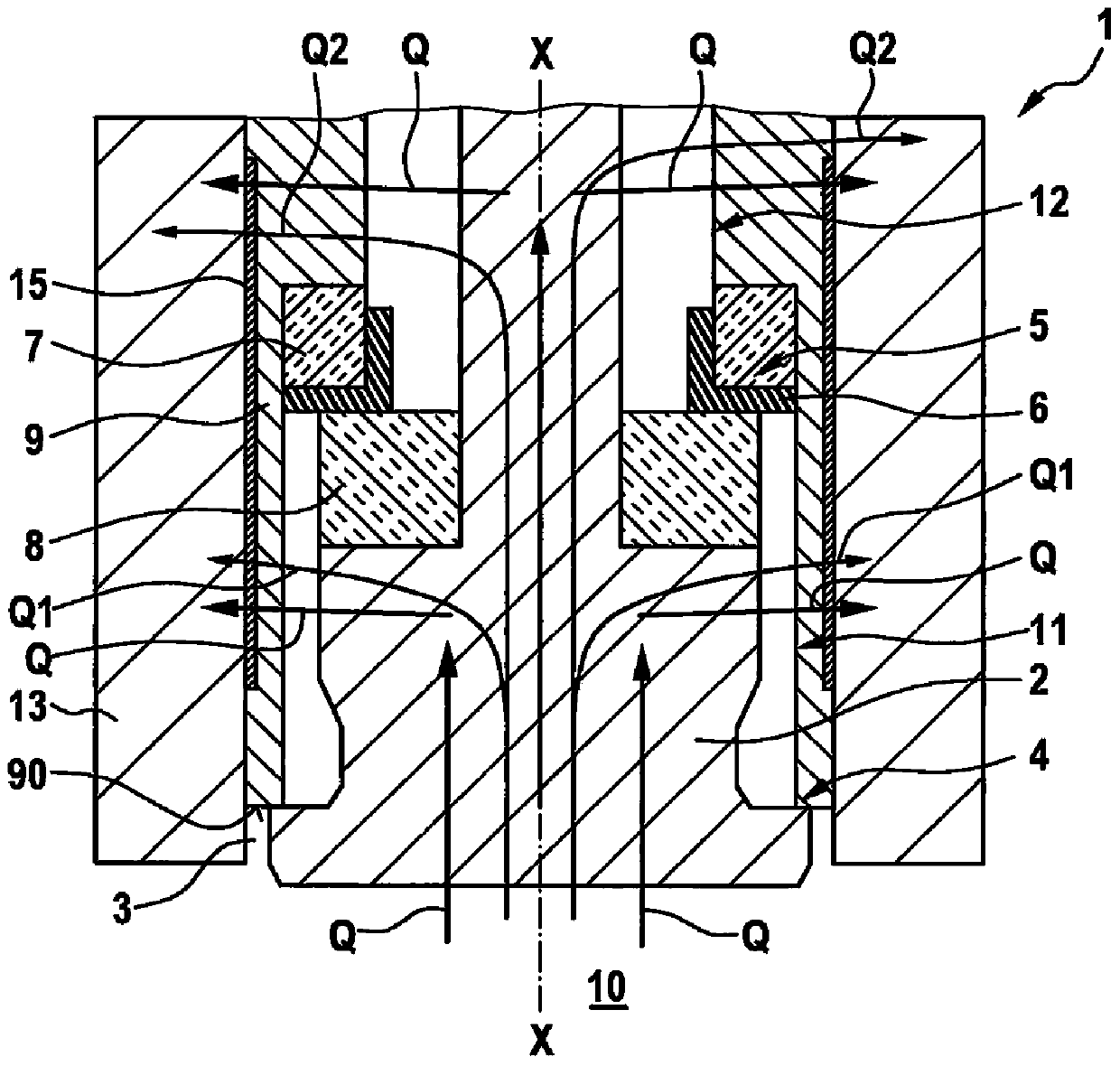

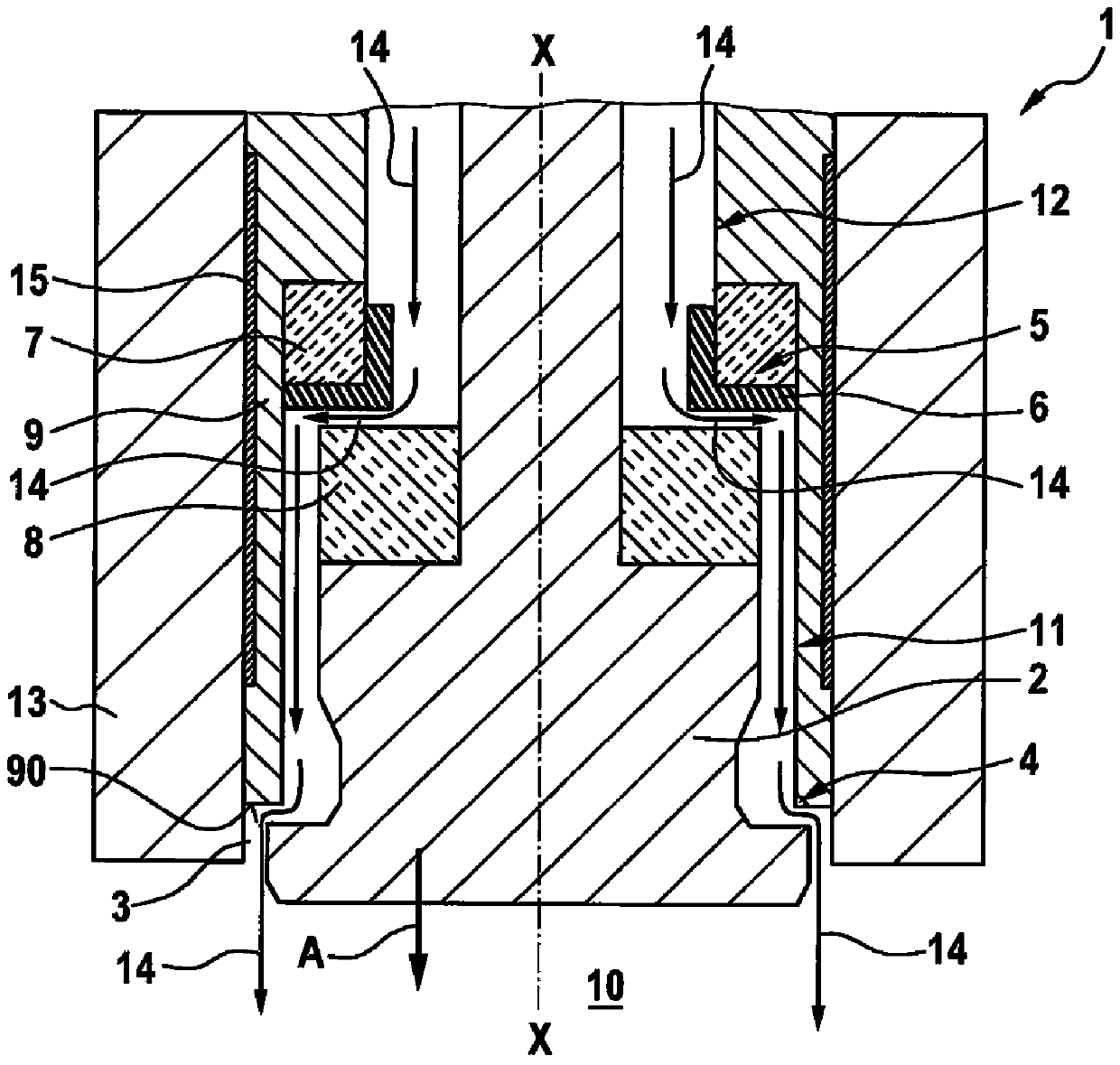

[0022] Refer to the attached figure 1 and 2 A gas injector 1 for injecting gaseous fuel into a combustion chamber 10 of an internal combustion engine will be described in detail.

[0023] as available from figure 1 Gas injector 1 is an outwardly opening injector as seen in figure 2 marked with arrow A. The gas injector 1 comprises a valve closing element 2 , which in the present exemplary embodiment is a valve needle. The valve closing element 2 releases the passage opening 3 and closes it. In this case, the valve closing element 2 is actuated by means of an actuator not shown, for example an electromagnetic actuator or a piezoelectric actuator.

[0024] The gas injector 1 also comprises a first elastomer-free sealing seat 4 and a second sealing seat 5 comprising at least one elastomeric sealing element 6 . The first sealing seat 4 without elastic body is, for example, a metal sealing seat or a ceramic sealing seat. Combinations of metal and ceramic seal seats are also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com