Anti-cutting fiber and preparation method and application thereof

A cut-resistant and fiber-resistant technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problem that the cut-resistant performance of gloves cannot be achieved, and achieve the effect of superior cut-resistant performance, strong versatility, and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

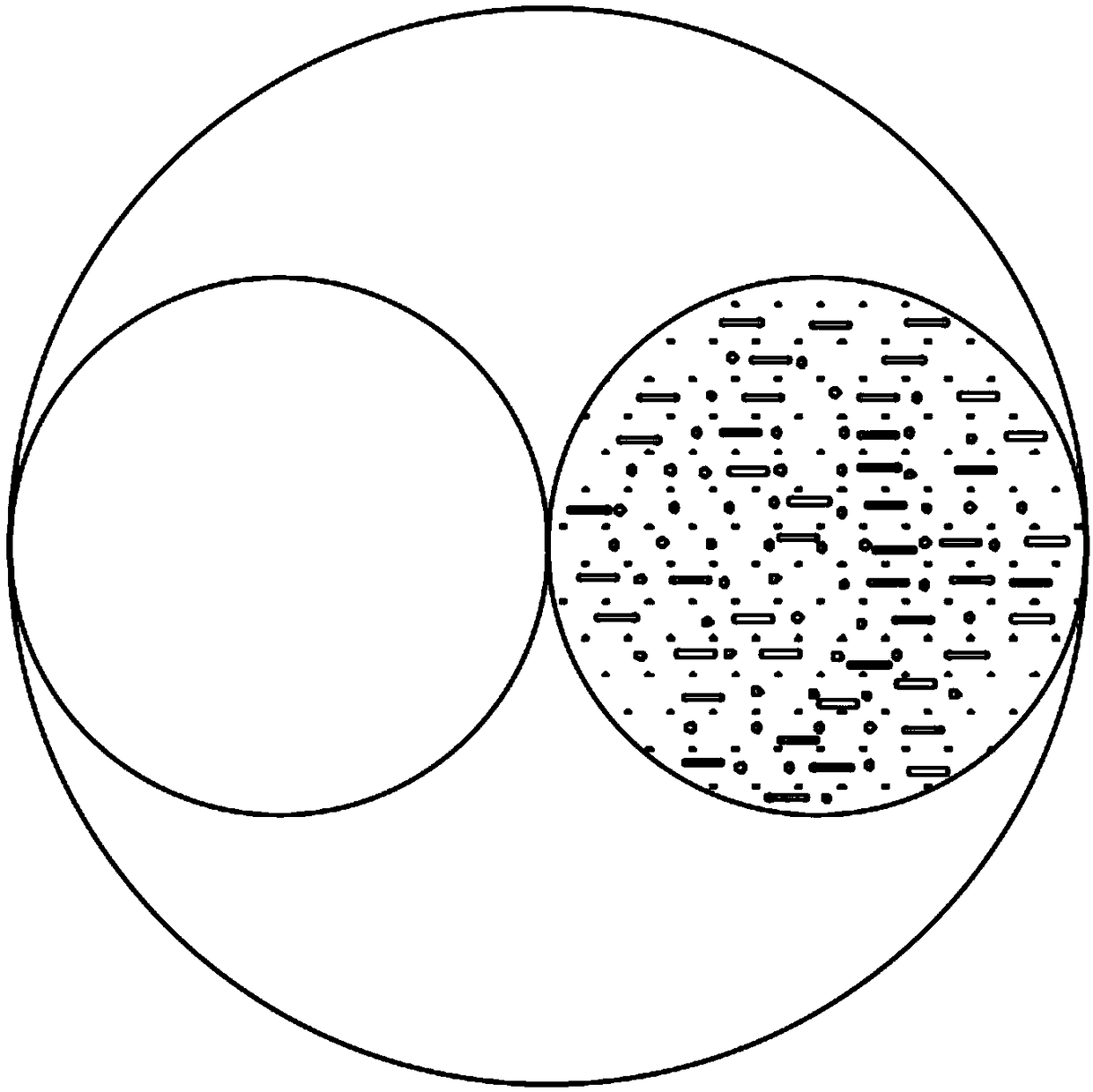

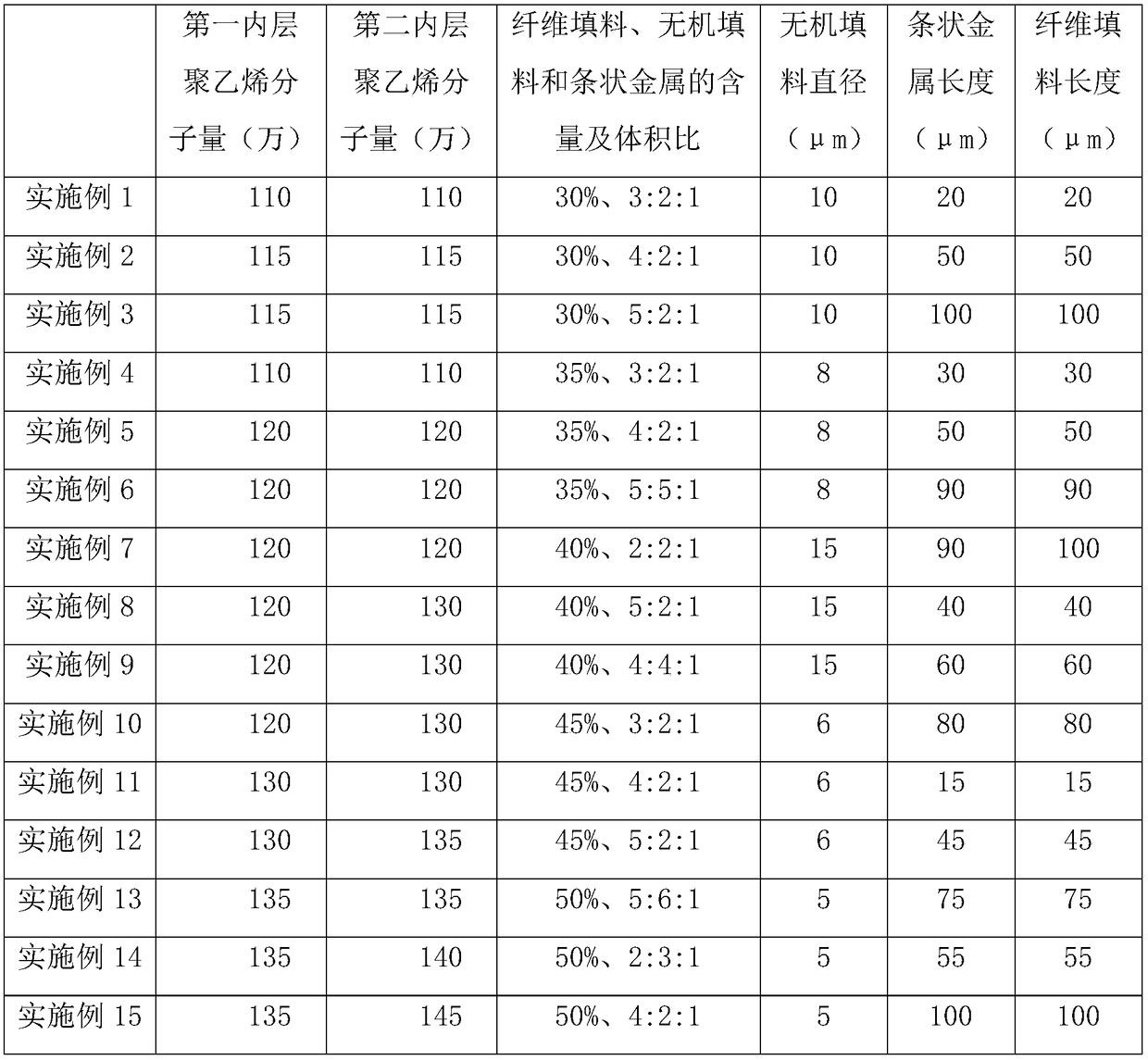

[0030] The embodiment of the present invention discloses a cut-resistant fiber, the cut-resistant fiber is in a crimped shape, the cross-section of the cut-resistant fiber is a multi-layer structure, and the multi-layer structure includes an outer layer and a second layer arranged in the outer layer An inner layer and a second inner layer, the outer layer is made of polyethylene, and the second inner layer is evenly distributed with 30% volume content of fiber filler, inorganic filler and strip metal.

[0031] The first inner layer is made of polyethylene with a molecular weight of 110, and the second inner layer is made of polyethylene with a molecular weight of 120.

[0032] The volume ratio range of the fibrous filler, the inorganic filler and the strip metal is 3:2:1.

[0033] The diameter of the inorganic filler is 10 microns, and the material of the inorganic filler is stainless steel, alloy steel, titanium alloy, glass or basalt.

[0034] The lengths of the strip metal...

Embodiment 22

[0104] The embodiment of the present invention discloses a method for preparing cut-resistant fibers. During melt spinning, the melts of the first inner layer and the second inner layer respectively enter the same spinneret hole through two extruders and injection ports, and The entrance of the spinneret hole is compounded with the melt of the outer layer. The first inner layer, the outer layer and the second inner layer are respectively extruded through three twin-screw extruders and then enter the composite spinning box, and then undergo winding, three-stage thermal stretching and heat setting treatment, and three The temperature ranges of the two twin-screw extruders are respectively 200°C, 220°C and 220°C, the speed of the winding is 1000m / min, the temperature range of the heat setting is 130°C, and the time range of the heat setting is 5min.

Embodiment 23

[0106] The embodiment of the present invention discloses a method for preparing cut-resistant fibers. During melt spinning, the melts of the first inner layer and the second inner layer respectively enter the same spinneret hole through two extruders and injection ports, and The entrance of the spinneret hole is compounded with the melt of the outer layer. The first inner layer, the outer layer and the second inner layer are respectively extruded through three twin-screw extruders and then enter the composite spinning box, and then undergo winding, three-stage thermal stretching and heat setting treatment, and three The temperature ranges of the two twin-screw extruders are respectively 200°C, 230°C and 220°C, the speed of the winding is 1100m / min, the temperature range of the heat setting is 125°C, and the time range of the heat setting is 8min.

[0107] Implement the present invention, have following beneficial effect:

[0108] (1) The cut-resistant fiber of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com