Biomass particle burner with vane drum type furnace bridge

A biomass particle and drum furnace technology, which is applied in the direction of combustion equipment, solid fuel combustion, lighting and heating equipment, etc. It can solve the abnormal combustion conditions in the furnace, the impact on production and life, and the grate is easy to slag and block, etc. problems, to achieve the effect of solving difficult slag removal, short slag removal time, improving combustion efficiency and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

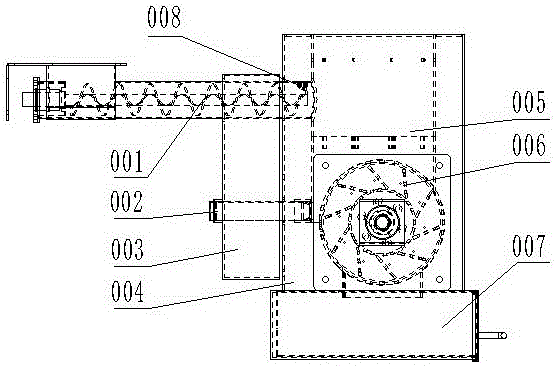

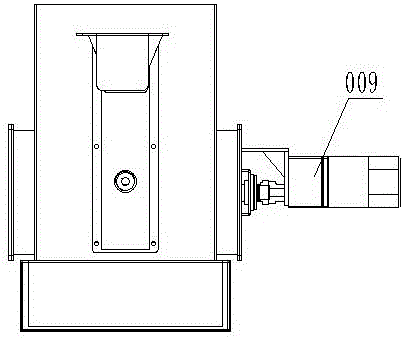

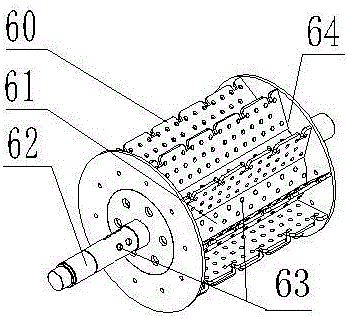

[0020] A blade drum type furnace bridge biomass particle burner, which consists of a combustion part and a slag discharge part. The combustion part consists of a combustion chamber (005), an auger feeder (001), an igniter (002), a setting The air channel chamber (004) outside the combustion chamber is composed of the air supply box (003) arranged on the side of the air duct chamber. The air channel chamber and the air supply box are set, and the slag discharge part is composed of the blade drum type furnace bridge (006), the slag receiving box (007) arranged under the blade drum type furnace bridge, and the transmission device that drives the blade drum type furnace bridge to rotate (009), the blade drum type furnace bridge is composed of a drum shaft (62), a drum (61) and a blade (60), the drum shaft and the drum are both hollow cylinders, and the drum shaft and the drum are Ventilation holes (63) are all provided, the blades are arranged on the drum, and the drum shaft is sl...

Embodiment 2

[0027] A blade drum type furnace bridge biomass particle burner, which is composed of a combustion part and a slag discharge part. The air supply box on one side of the air duct chamber is composed of the slag discharge part arranged under the combustion chamber, the auger feeder and igniter are arranged through the air duct chamber and the air supply box, and the slag discharge part is composed of The blade drum type furnace bridge is composed of a slag receiving box arranged under the blade drum type furnace bridge, and a transmission device that drives the rolling furnace bridge to rotate. The blade drum type furnace bridge is composed of a drum shaft, a drum and blades. The drum Both the shaft and the drum are hollow cylinders, and ventilation holes are arranged on the drum shaft and the drum, and the blades are arranged on the drum.

[0028] There are ten blades, and each blade is provided with a plurality of oxygen supply ventilation holes.

[0029] The edges of the bla...

Embodiment 3

[0034] A blade drum type furnace bridge biomass particle burner, which is composed of a combustion part and a slag discharge part. The air supply box on one side of the air duct chamber is composed of the slag discharge part arranged under the combustion chamber, the auger feeder and igniter are arranged through the air duct chamber and the air supply box, and the slag discharge part is composed of The blade drum type furnace bridge is composed of a slag receiving box arranged under the blade drum type furnace bridge, and a transmission device that drives the rolling furnace bridge to rotate. The blade drum type furnace bridge is composed of a drum shaft, a drum and blades. The drum Both the shaft and the drum are hollow cylinders, and ventilation holes are arranged on the drum shaft and the drum, and the blades are arranged on the drum.

[0035] There are sixteen blades, and each blade is provided with a plurality of oxygen supply ventilation holes.

[0036] The edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com