Method of improving laser tracker station moving precision based on photogrammetry

A technology of laser tracker and photogrammetry, which is applied in the field of measurement and can solve problems such as large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

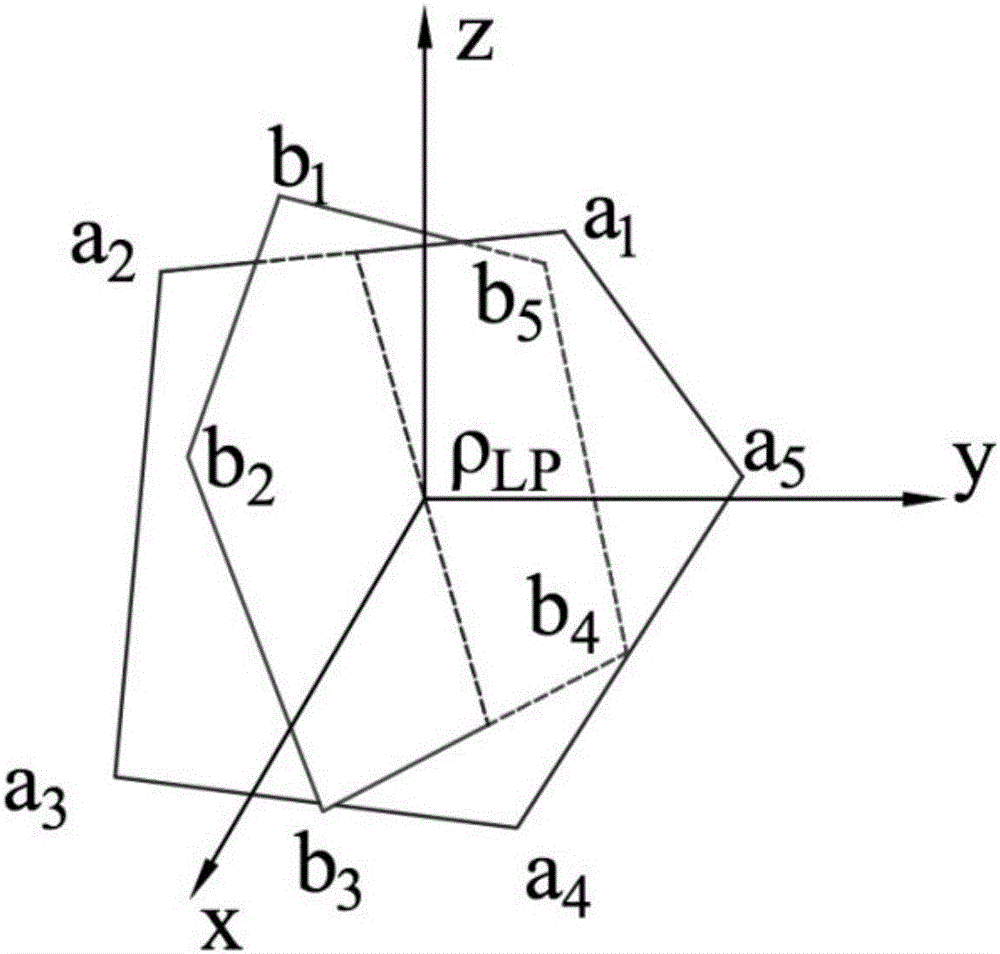

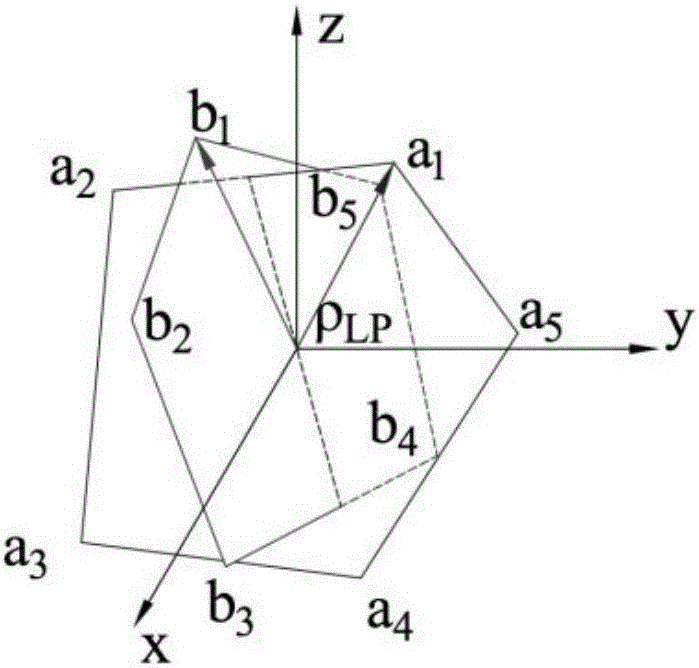

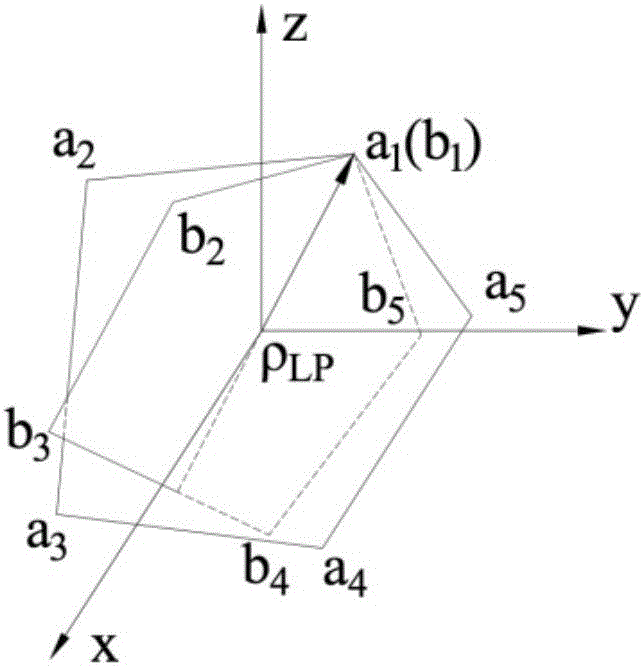

Image

Examples

Embodiment Construction

[0054] specific implementation plan

[0055] The present invention will be further described in detail below in conjunction with accompanying drawings and examples.

[0056] In order to achieve the above object, the present invention provides a method for improving the accuracy of the laser tracker transfer station based on photogrammetry. The equipment used in the method includes: at least one laser tracker for the measurement of target objects and public points; at least A laser tracker control cabinet, connected with the laser tracker; at least one laser tracker target ball, used as the laser tracker to measure the target; a digital camera, used for photogrammetry, to take pictures; multiple photogrammetry target balls, Used as a photogrammetric target; multiple target ball mounts for holding two types of target balls; multiple marker points, glued near a common point; at least one reference ruler for photogrammetric calibration; at least one workstation, with a laser track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com