Separation Method of Systematic Error and Random Error of Discontinuous Machining Surface

A technology for machining surfaces and systematic errors, applied in measurement devices, instruments, optical devices, etc., can solve the problem of inability to apply discontinuous surface error separation, and achieve the effect of high separation efficiency and accurate separation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

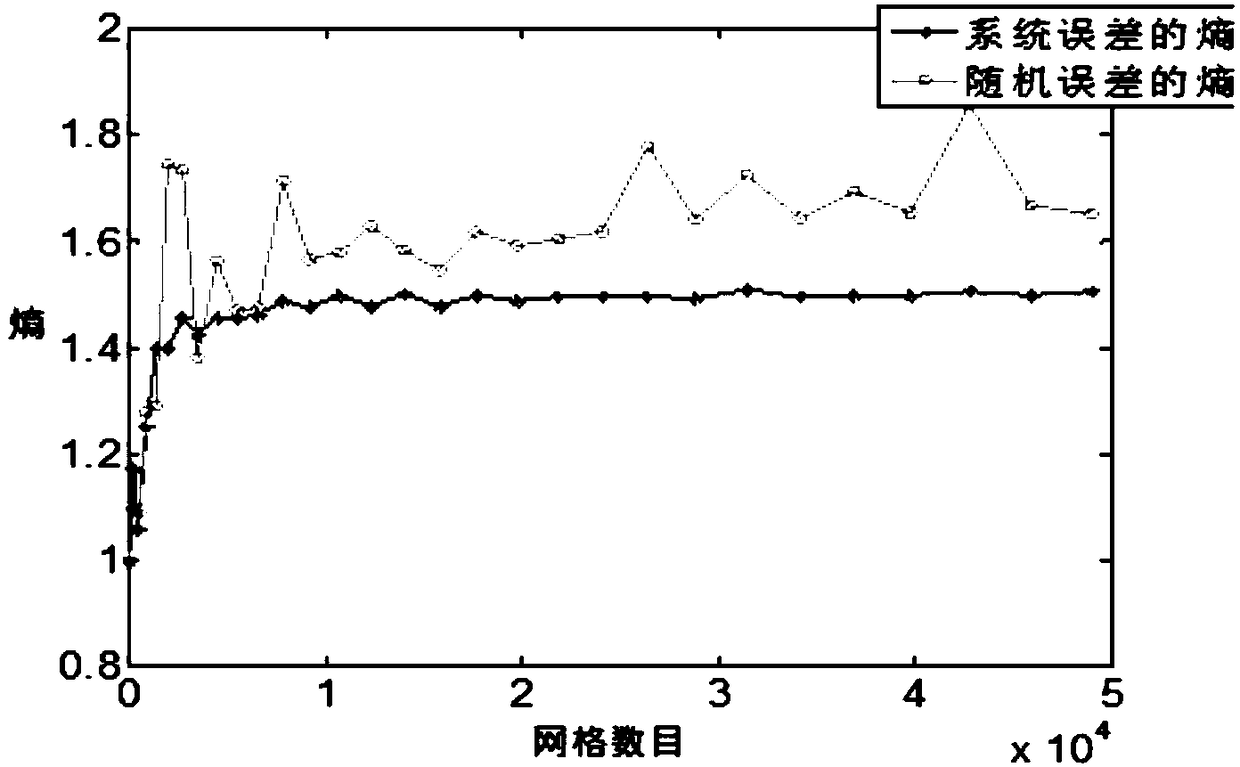

[0039] The method for separating the systematic error and random error of the discontinuous machining surface, the specific steps are as follows:

[0040] Step 1. Preliminary separation method of non-continuous machining surface errors

[0041] 1-1 Acquisition of small triangle faces

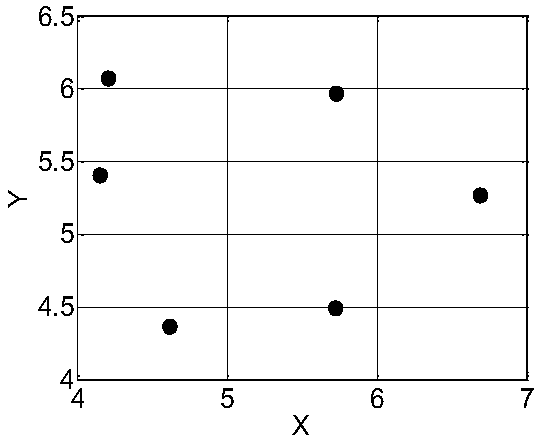

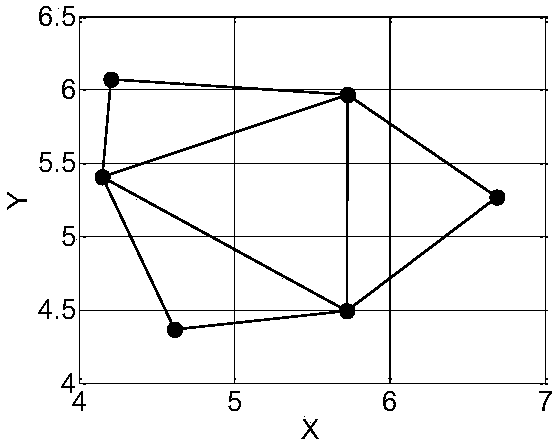

[0042] Firstly, the data of the discontinuous machining surface topography error E must be obtained by measurement, such as figure 1 shown. Use the Delaunay triangulation algorithm to operate the measured data of the surface topography to obtain multiple small triangular patches, such as figure 2 shown. The three vertices V corresponding to each small triangle face 1 ,V 2 ,V 3 , three vertices V 1 ,V 2 ,V 3 There are three-dimensional coordinates: V 1 =(V x1, V y1, V z1 ), V 2 =(V x2, V y2, V z2 ), V 3 =(V x3, V y3, V z3 ).

[0043] 1-2 Grid division

[0044] Mesh the machined surface, figure 1 , figure 2 The dotted lines in represent grids. Now divide the surface int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com