A detection method and detection system of a rotary magnetic float level gauge

A float level and detection method technology, applied in the field of liquid level gauges, can solve the problems of cumbersome correction of specific gravity adjustment and detection results, unmeasurable rotation resistance of liquid level gauges, and inability to achieve adjustment and correction, etc., and achieve simple and feasible calibration and calibration , It is convenient to judge the performance and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

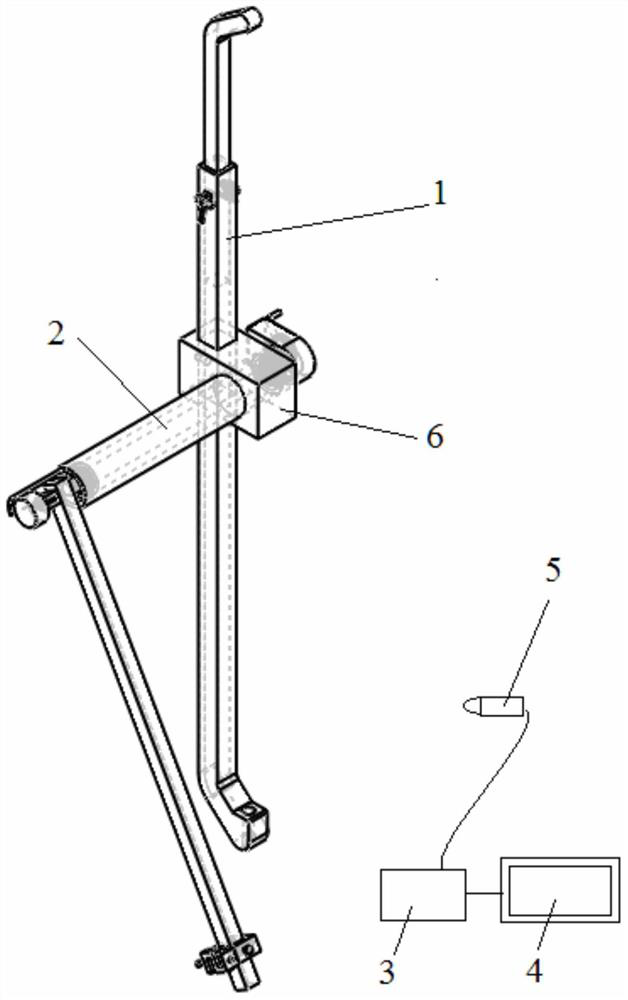

[0037] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

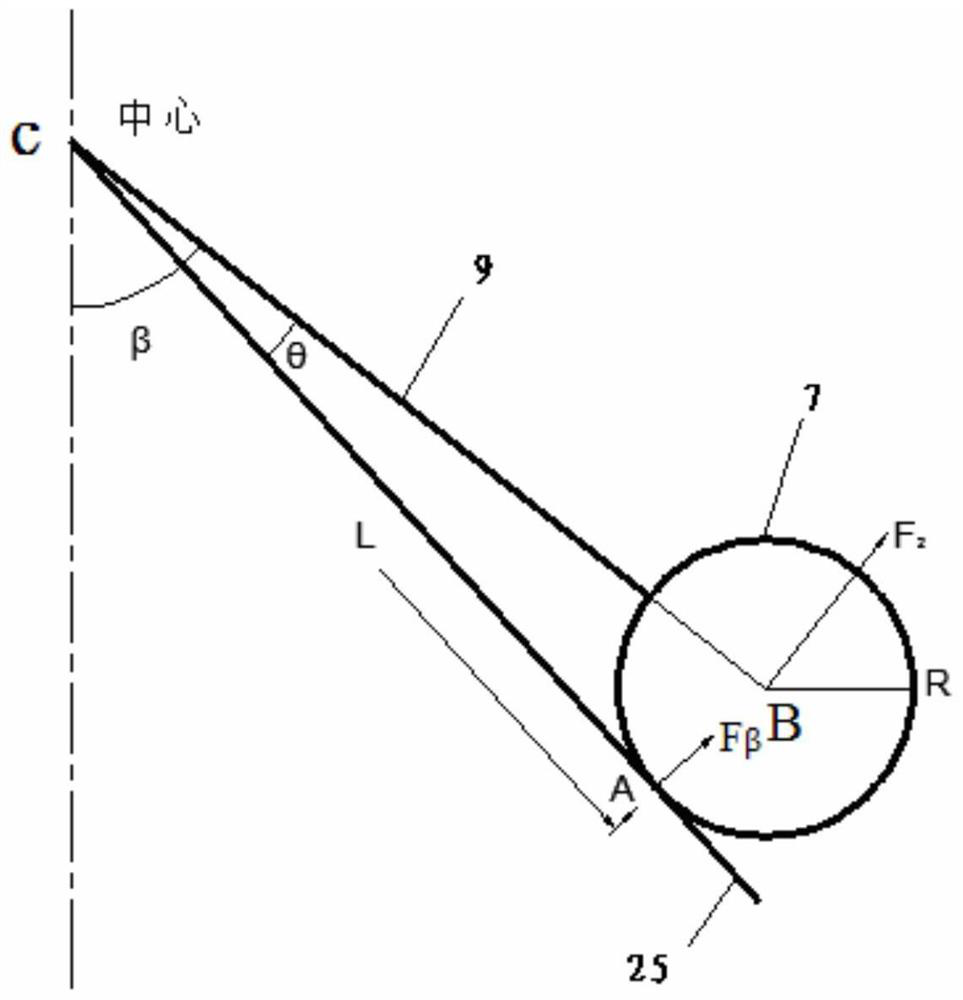

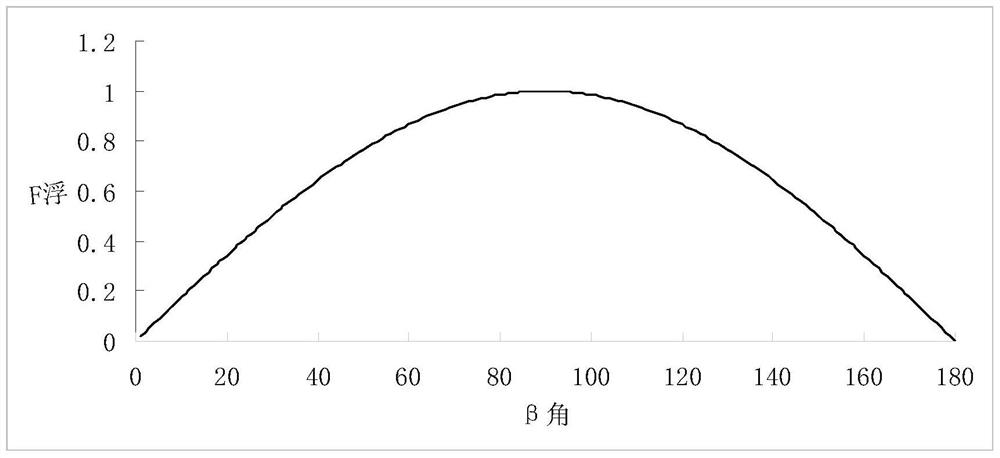

[0038] Such as figure 1 and figure 2 As shown, the detection method of the rotary magnetic float level gauge of the present invention comprises the following steps:

[0039] A. The rotating rod installed with the pressure sensor pushes the liquid level gauge float to rotate at a constant speed;

[0040] B. The horizontal axis of the rotating rod is concentric with the rotation center of the liquid level gauge, that is, the relative position of the floating ball and the rotating rod is fixed, the rotation angle of the rotating rod is the same as that of the floating ball, and the contact of the pressure sensor is only for the floating ball. The ball has a driving force, that is, the driving force is perpendicular to the floating ball;

[0041] C. During the rotation process, the pressure sensor measures the resistance F in the direction of ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com