Amorphous alloy spectacles frame and manufacture method thereof

A technology of amorphous alloy and spectacle frame, which is applied in the application field of amorphous alloy, can solve the problems of poor environmental corrosion resistance, time-consuming and labor-intensive, and unstable, etc., achieve strong environmental corrosion resistance, reduce production costs, and simplify production The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

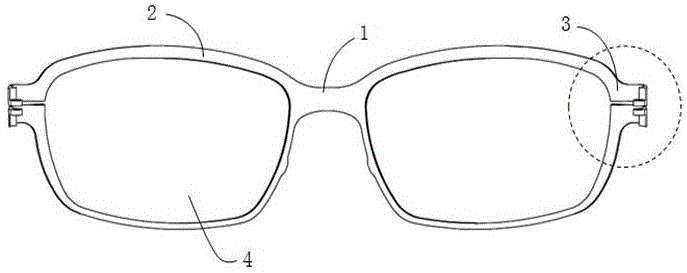

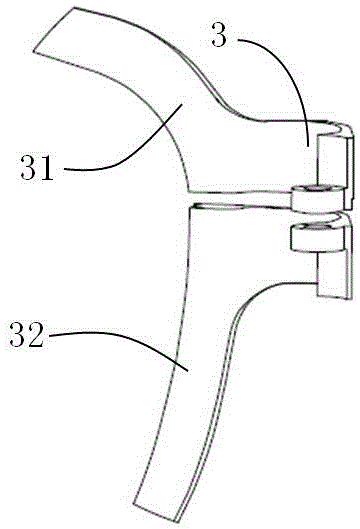

[0032] (1) Example 1: Preparation of zirconium-based amorphous alloy spectacle frame

[0033] The steps of the preparation method of the zirconium-based amorphous alloy spectacle frame are as follows:

[0034] Step 1, placing the metal support piece in the mold for casting.

[0035] Stainless steel 304 is selected as the material of the metal support, and the stainless steel support is surrounded by a raised part, and the height of the raised part is set to 0.4mm that is suitable for the subsequent embedded lens;

[0036] In the second step, the die-casting of the amorphous alloy spectacle frame is carried out by using the mold inserted into the metal support. The die-casting process is vacuum die-casting, the vacuum degree is 10Pa, the feed temperature is kept at 980°C, the energy storage pressure of the die-casting machine is 120MPa, the injection speed is 0.8m / s, the molding time is 3s, and the cooling speed is 10 6 °C / s, after complete cooling, a composite body of amorph...

Embodiment 2

[0044] (2) Example 2: Preparation of copper-based amorphous alloy spectacle frame

[0045] Adopt the same preparation method as in Example 1 to prepare a copper-based amorphous alloy spectacle frame:

[0046] Step 1, placing the metal support piece in the mold for casting.

[0047] The high-temperature alloy GH2036 is selected as the material of the metal support, and the stainless steel support is surrounded by raised parts, and the height of the raised part is set to 1.5 mm to match the subsequent embedded lenses;

[0048] In the second step, the casting of the amorphous alloy spectacle frame is carried out by using the mold inserted in the metal support. The die-casting process is vacuum die-casting, the vacuum degree is 10Pa, the feed temperature is kept at 960°C, the energy storage pressure of the die-casting machine is 100MPa, the injection speed is 1.2m / s, the molding time is 3s, and the cooling speed is 10 6 °C / s, after complete cooling, a composite body of amorphous...

Embodiment 3

[0052] (3) Example 3: Preparation of Titanium-based Amorphous Alloy Spectacle Frame

[0053] Adopt the same preparation method as in Example 1 to prepare a titanium-based amorphous alloy spectacle frame:

[0054] Step 1, placing the metal support piece in the mold for casting.

[0055] The heat-resistant steel ZG40Cr9Si2 is selected as the material of the metal support, and the stainless steel support is surrounded by raised parts, and the height of the raised part is set to 0.8mm suitable for the subsequent embedded lenses;

[0056] In the second step, the casting of the amorphous alloy spectacle frame is carried out by using the mold inserted in the metal support. The die-casting process is vacuum die-casting, the vacuum degree is 5Pa, the feed temperature is kept at 980°C, the energy storage pressure of the die-casting machine is 110MPa, the injection speed is 1.0m / s, the molding time is 4s, and the cooling rate is 3.25×10 5 ℃ / s, after complete cooling, a composite of amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com