High-speed train set body elastic mode vibration control method

A high-speed EMU and elastic mode technology, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of high cost, complicated control method and difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

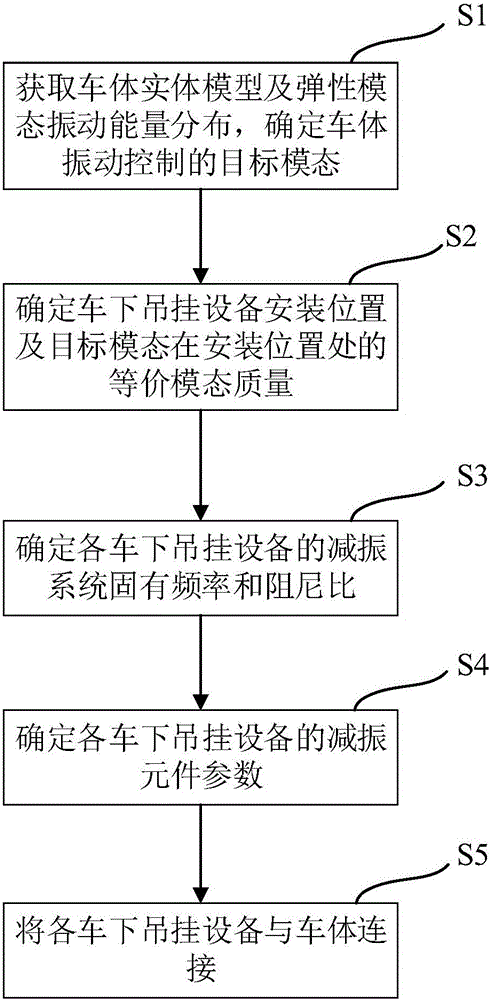

[0068] Such as figure 1 As shown, a method for controlling elastic modal vibration of a high-speed EMU car body is used to control the vibration of a high-speed EMU car body. The method includes the following steps:

[0069] S1. Obtain the solid model of the vehicle body, analyze the vibration of the vehicle body, obtain the energy distribution of the elastic mode vibration, and determine the target mode of the vehicle body vibration control; the determined target mode of the vehicle body vibration control can be a certain order mode , and can also be certain modes.

[0070] This step S1 specifically includes the following steps:

[0071] S1.1. Obtain the solid model of the car body, perform finite element modal analysis on the solid model, and determine the elastic modal frequency of the car body. The finite element model is in the ready state and there is no hanging equipment under the car;

[0072] S1.2. Establish a rigid-flexible coupled dynamic model of the car body inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com