Livestock and poultry bone grinding-tooth-type crushing apparatus and method

A technology of crushing device and livestock and poultry bones, which is applied in the direction of grain processing, etc., can solve the problems that a single crushing equipment cannot achieve the crushing effect, the requirements for land occupation and auxiliary equipment are high, and the generality of conventional crushers is poor, and the floor space is small. , Solve the effect of poor versatility and increase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0048] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

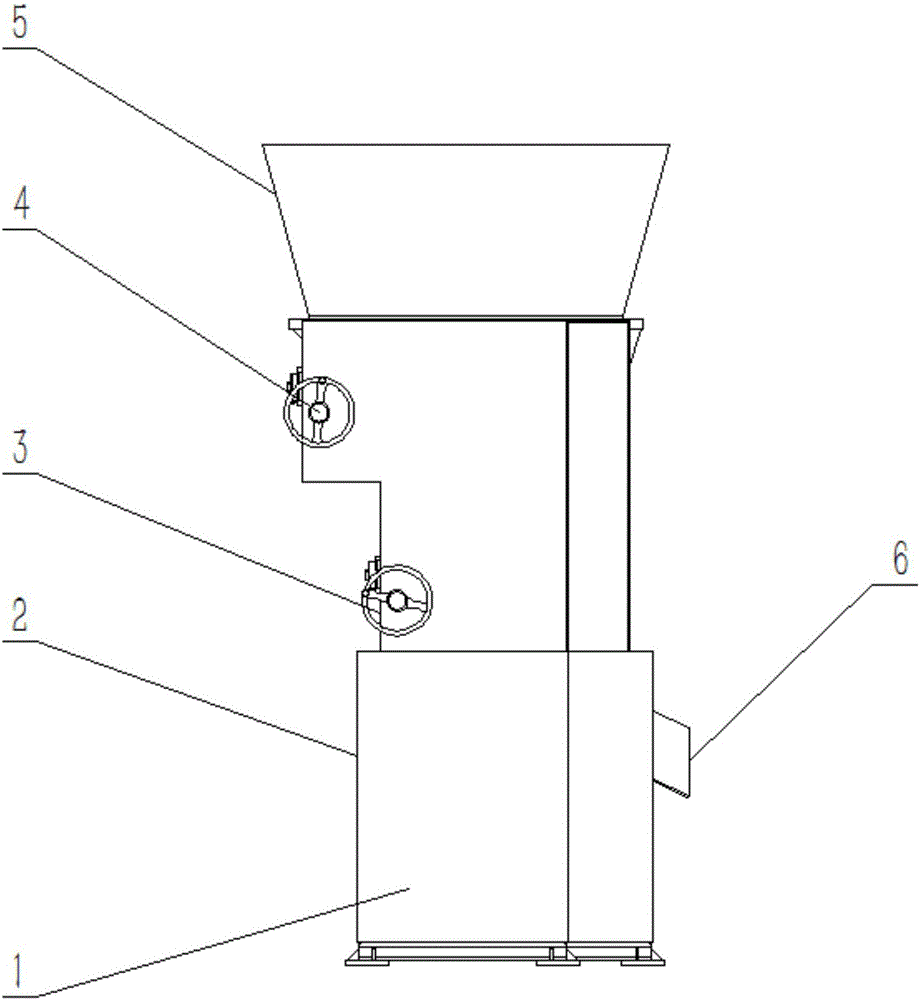

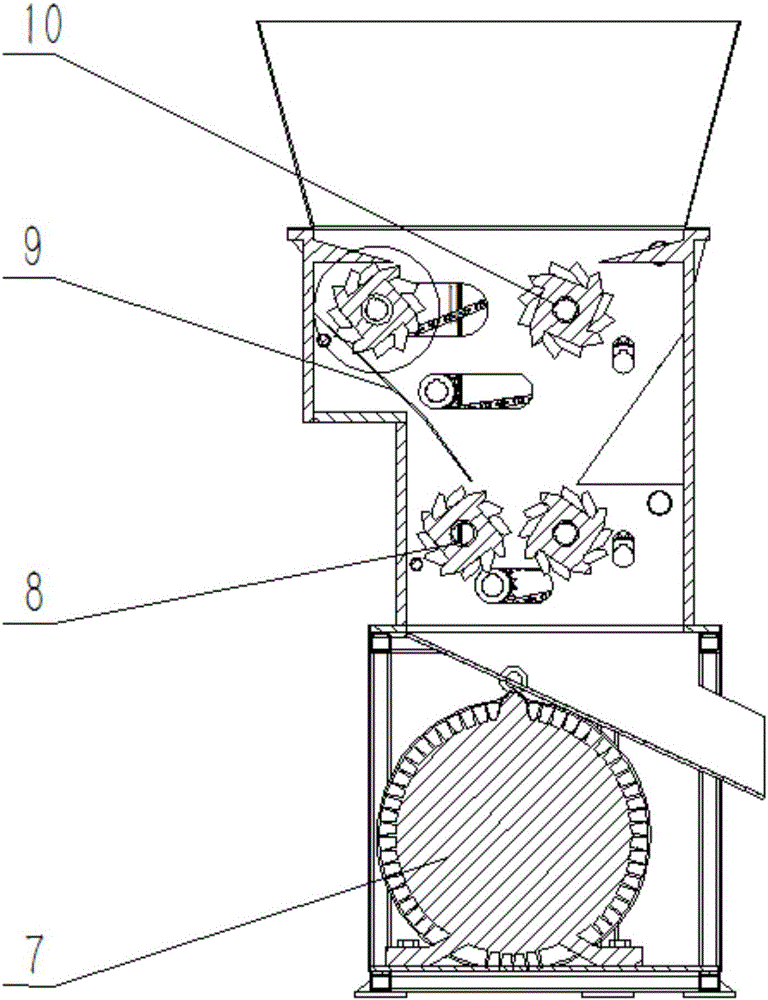

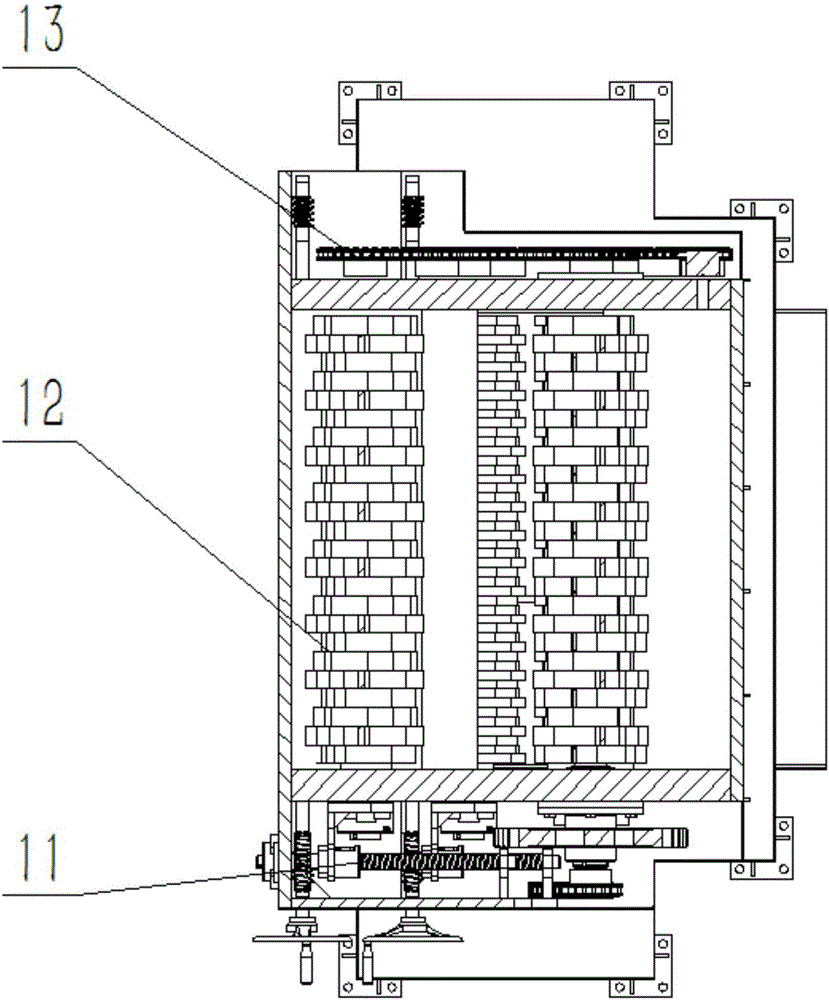

[0049] Such as Figure 1~5 As shown, the present invention provides a rodent crushing device for livestock and poultry bones, comprising:

[0050] Rack 1, which is a hollow structure and arranged along the vertical direction;

[0051] A primary crushing device, which is horizontally arranged in the hollow structure of the frame 1 along the horizontal axis of the frame 1, and the two ends are respectively rotatably fixed on both sides of the frame 1, and rotates under the drive of the drive mechanism; and

[0052] A secondary crushing device, which is also horizontally arranged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com