Frame glue coating method, frame glue structure and liquid crystal box

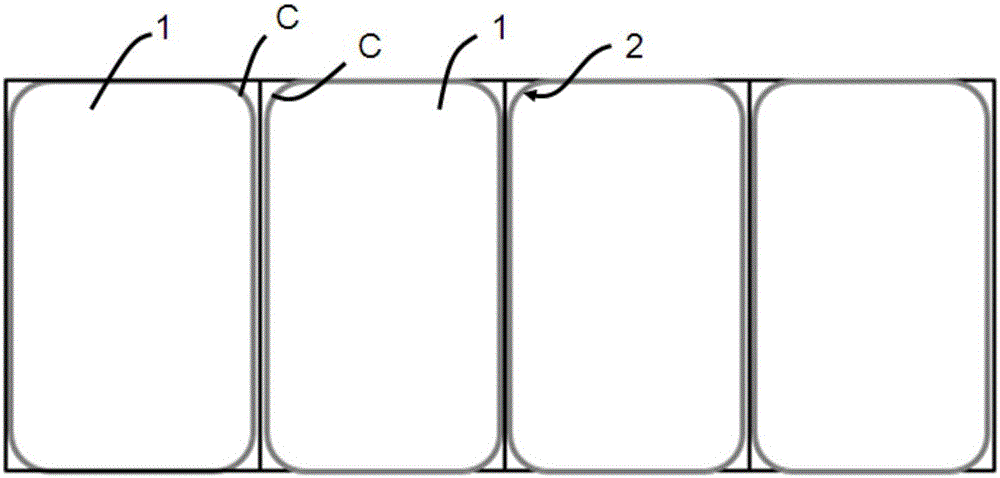

A coating method and frame glue technology, which is applied to the surface coating liquid device, coating, optics, etc., can solve the problem of the difficulty of sealing uniformity at the corner C, reduce common defects, reduce coating difficulty, The effect of reducing the incidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

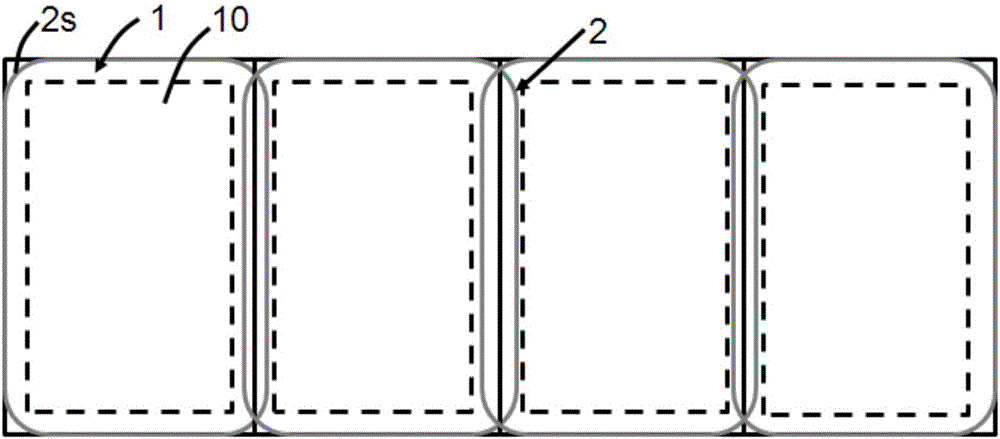

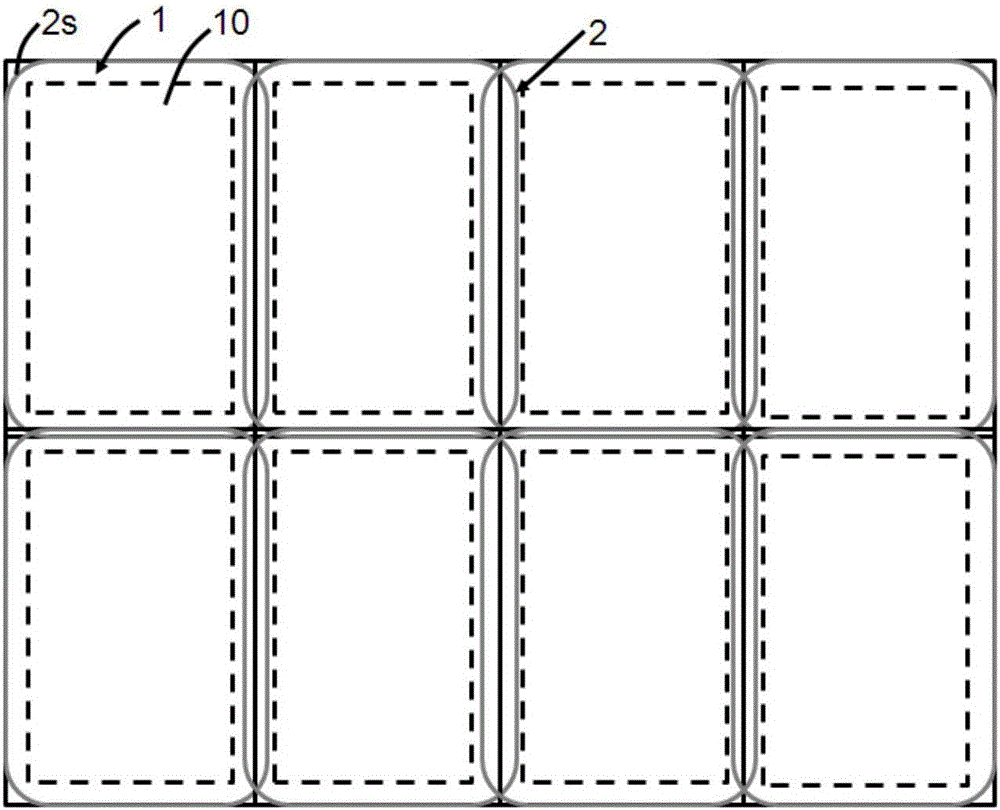

[0019] refer to figure 2 , in the frame glue coating process of the embodiment of the present invention, a number of spaced display areas 10 are formed in an array on each motherboard 1, and each display area 10 is coated with a circle surrounding the corresponding display area 10. The frame glue 2, the four corners 2s of each frame glue 2 are rounded corners, and at least in the same row or column, two adjacent four corners 2s of every two adjacent frame glue 2 overlapping.

[0020] Compared with the prior art, since the ring-shaped frame glue 2 outside the single display area 10 has a large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com