Rolling mill emulsion system water adding method and rolling mill emulsion system

An emulsion system and emulsion technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of low efficiency, high labor intensity and high error rate, reduce labor intensity, improve the efficiency of water replenishment, and ensure effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

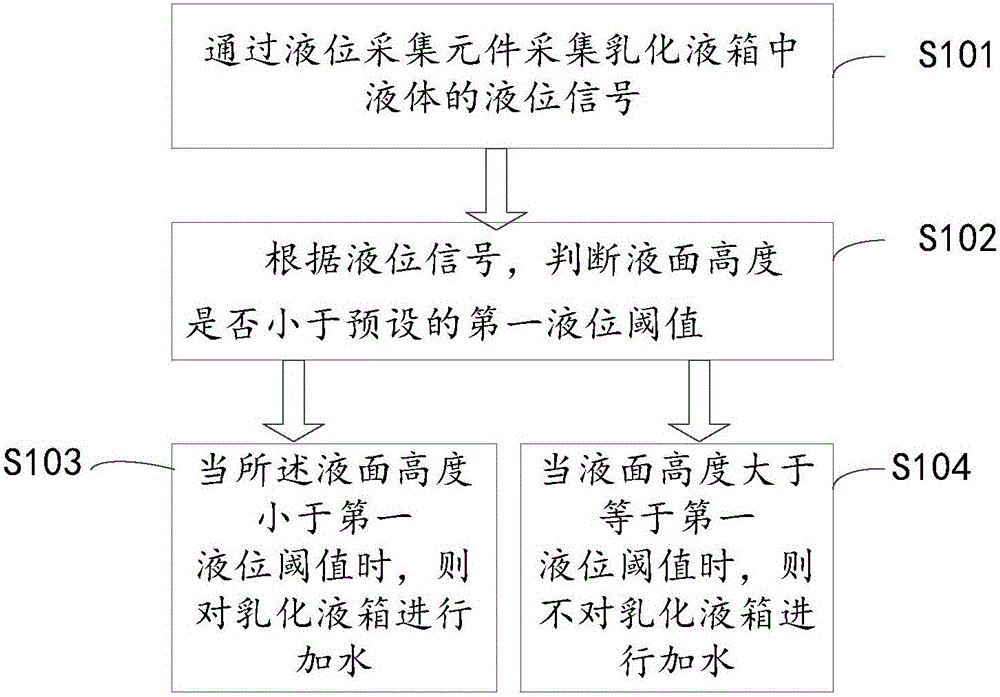

[0039] In this embodiment, a method for adding water to the emulsion system of a rolling mill is provided, please refer to figure 1 , figure 1 It is a step diagram of the method for adding water to the emulsion system of the rolling mill in the embodiment of the present application, such as figure 1 As shown, the method includes:

[0040] Step S101, collecting the liquid level signal of the liquid in the emulsion tank through the liquid level acquisition element; the liquid level signal is used to represent the liquid level of the liquid;

[0041] Step S102, according to the liquid level signal, judging whether the liquid level is lower than a preset first liquid level threshold;

[0042] Step S103, when the liquid level is lower than the first liquid level threshold, add water to the emulsion tank;

[0043] Step S104, when the liquid level is greater than or equal to the first liquid level threshold, then do not add water to the emulsion tank.

[0044] Combine below figu...

Embodiment 2

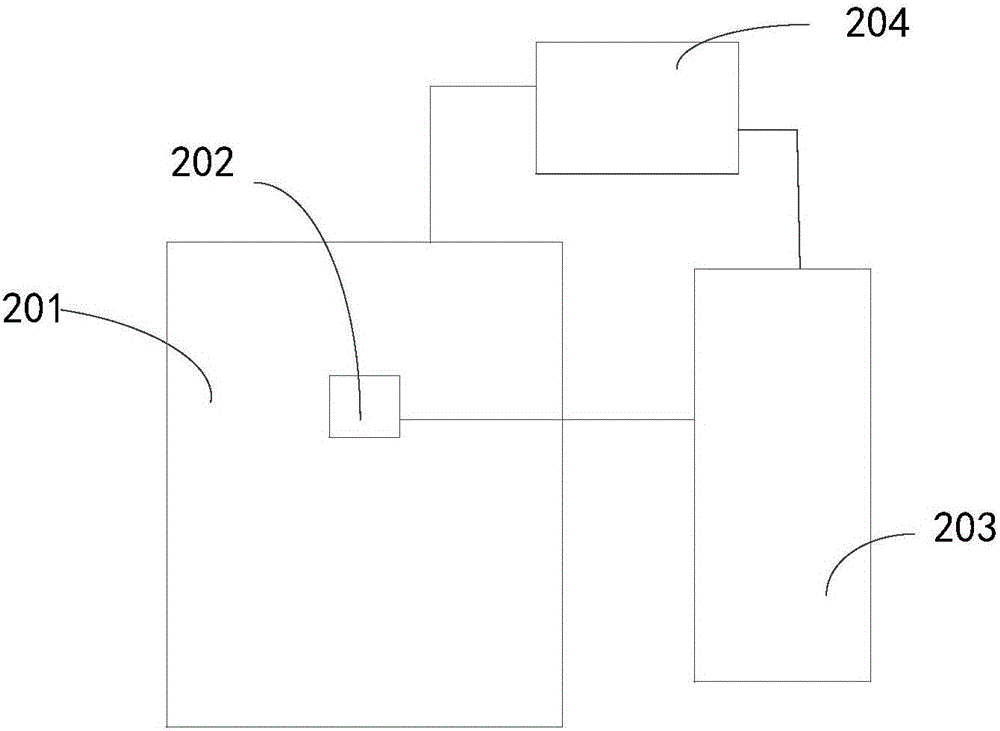

[0073] In this embodiment, a rolling mill emulsion system is provided, please refer to figure 2 , figure 2 It is a structural schematic diagram of the rolling mill emulsion system in the embodiment of the present application, such as figure 2 As shown, the system includes:

[0074] The emulsion tank 201 and the liquid level acquisition element 202 arranged on the emulsion tank 201, the liquid level acquisition element 202 is used to collect the liquid level signal of the liquid in the emulsion tank 201; the liquid level signal is used To characterize the liquid level of said liquid;

[0075] A judging module 203, connected to the liquid level acquisition element 202, for judging whether the liquid level is less than a preset first liquid level threshold according to the liquid level signal;

[0076] The water adding pipeline 204 is connected with the judging module 203, and is used to add water to the emulsion tank 201 when the liquid level is lower than the first liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com