Ultra-soft metal foil belt edge trimming tool

A metal foil strip and soft metal technology, applied in the field of ultra-soft metal foil strip edge cutting knife, can solve the problems of large resistance, rough cutting edge, not sharp, etc., achieve the effect of improving stability and reliability, and solving roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

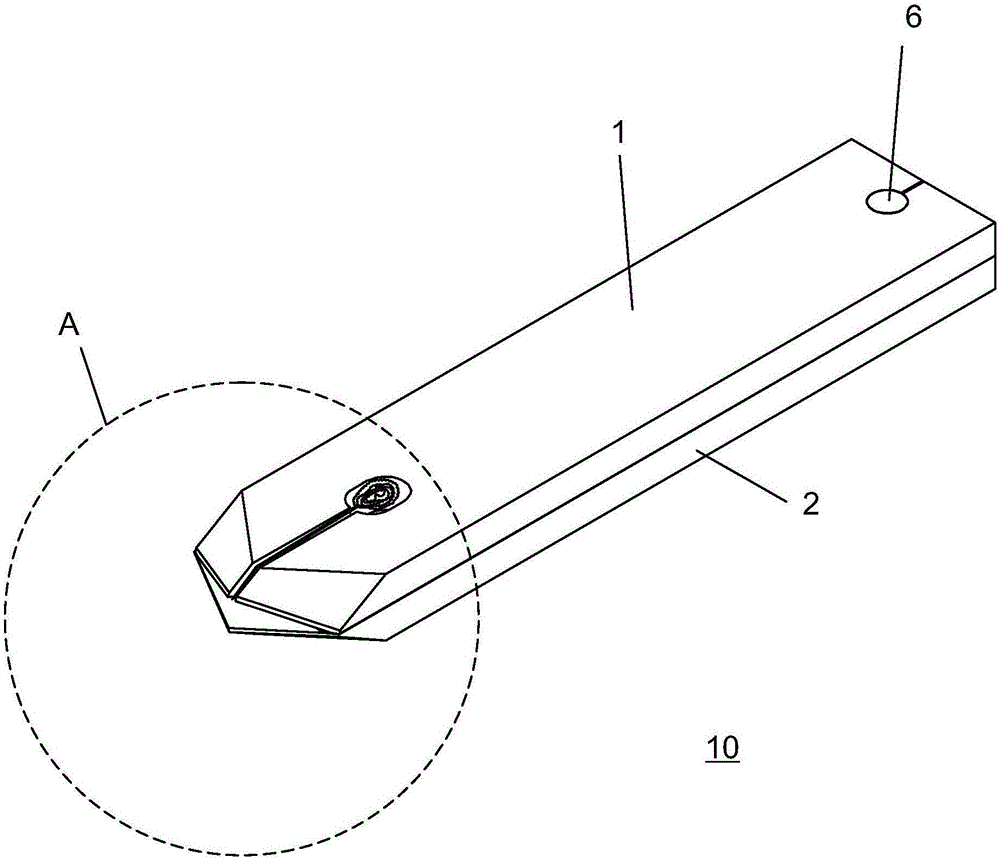

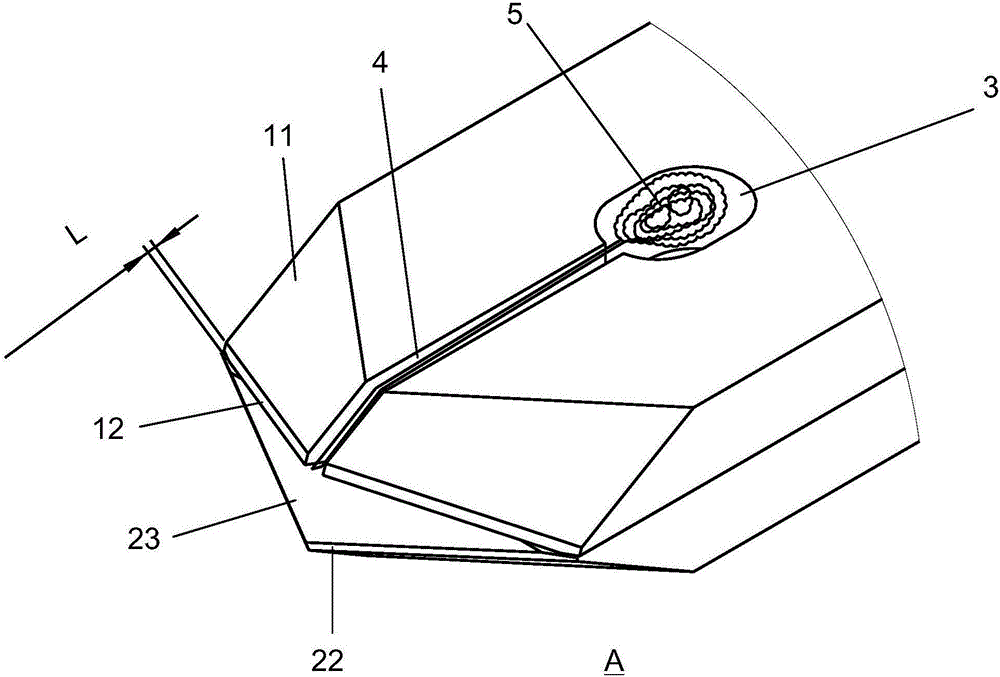

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] see Figure 1 ~ Figure 3 As shown, the ultra-soft metal foil band trimming knife 10 of the present invention comprises upper and lower blades 1,2, and the upper and lower blades 1,2 are stacked, and the tails of the upper and lower blades 1,2 are movably connected, and the upper and lower blades 1,2 are flexibly connected. 1. The heads of the lower blades 1 and 2 are in an isosceles triangle shape, and the upper surface of the upper blade 1 head is composed of the first wedge surface 11 and the second wedge surface 12 that are obliquely downward. The lower surface is formed by the obliquely upward third wedge surface 13, and the upper blade is jointly formed by the second and three wedge surfaces 12 and 13. The lower surface of the head is composed of the fourth wedge surface 21 and the fifth wedge surface 22 that are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com