Split sealing structure for piston core of loader booster pump

A technology of sealing structure and booster pump, which is applied in the direction of hydraulic brake transmission, etc., can solve the problems of easy fatigue damage of seals, insufficient braking pressure, and reduced braking force, so as to reduce the cost of maintenance parts, improve efficiency, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

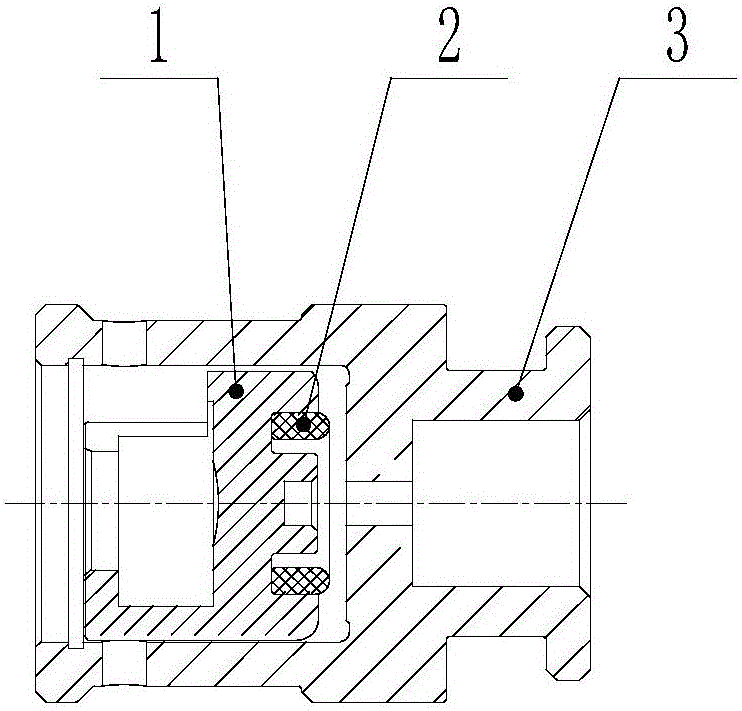

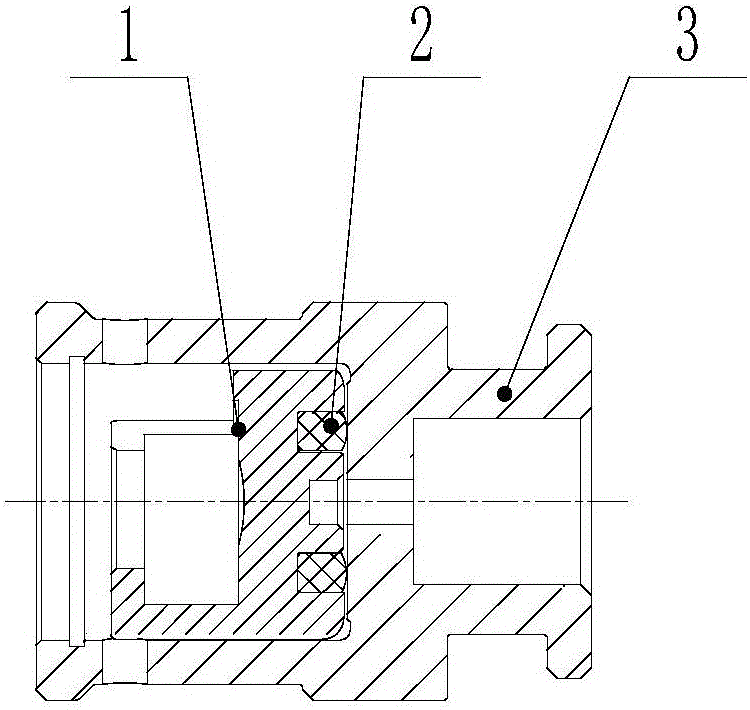

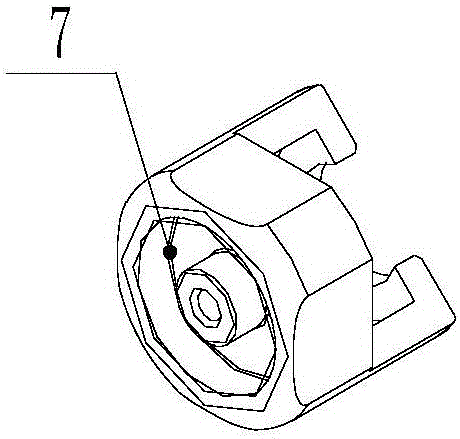

[0018] Such as Figure 1 to Figure 4 As shown, a loader afterburner pump piston core split seal structure, including piston core 1, seal 2 and piston 3, piston core 1 is provided with a seal groove 7 to cooperate with seal 2, piston core 1 and seal Part 2 adopts a split seal structure, that is, the piston core 1 and the seal 2 are two independent structures, which can be replaced separately when damaged, and the seal groove 7 and the seal 2 are interference fit, and the cut-off of the seal groove 7 The area is larger than the cross-sectional area of the sealing member 2 to ensure that the sealing member 2 has a reasonable filling rate and compression rate; wherein, the sealing member 2 is an O-shaped or D-shaped or rectangular structure.

[0019] Such as Figure 5 As shown, when the loader is operating under the service brake, the compressed air pushes the air piston 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com