Stacking height real-time data acquisition system of stacking machine

A real-time data acquisition and stacker technology, which is applied to lifting devices, safety devices of lifting equipment, etc., can solve problems such as the height of coal stacks, and achieve the effects of high accuracy, convenient use and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following will be described in detail in conjunction with the embodiments of the present invention with reference to the accompanying drawings.

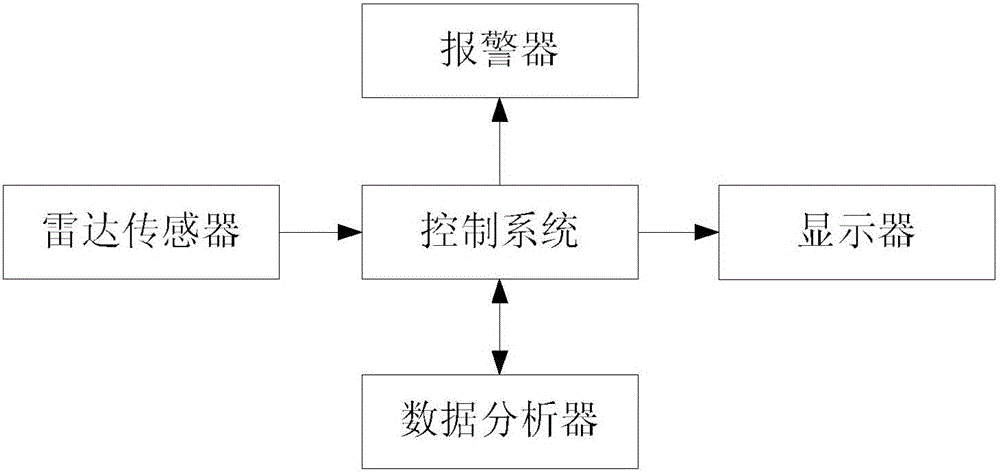

[0012] A stacking height real-time data acquisition system of a stacker, including a radar sensor and a control system, the radar sensor is unidirectionally connected to a data analyzer, the control system is unidirectionally connected to the data analyzer, and the control system is bidirectionally connected to an engineer station;

[0013] The radar sensor uses an induction head to sense the radar signal of the coal pile, and transmits the signal to the data analyzer, and the data analyzer sends the converted data signal to the control system, and the control system calculates the height data of the coal pile through a formula, and the two Two radar sensors get two height data, if the two height data errors are within the safe range, calculate the average value of the two heights, and display the data on the engineer stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com