A kind of preparation method of lightweight refractory material

A refractory material and lightweight technology, applied in the field of refractory material production, can solve the problems of low thermal conductivity, high corrosion resistance, etc., and achieve the effect of high strength and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] This embodiment provides a kind of preparation method of lightweight refractory material, comprises the following steps:

[0025] Step 1: Select magnesia and carbon as the reaction raw materials, grind the raw materials to be less than 0.088mm, mix them evenly according to the molar ratio of MgO and C at 1:1, and use them as part of the fine powder part of the refractory ingredients.

[0026] Step 2, batching the refractory raw materials according to a certain particle size distribution. The aggregate part can be lightweight aggregate or dense aggregate. Generally, the ratio of aggregate to fine powder is between 50-80:20-50, wherein the fine powder part contains MgO and C powder mixed in step 1. According to product requirements, the MgO and C powder account for the fine powder Part of 20% to 70%. In order to improve the uniformity of product quality, the fine powder part needs to be blended for 30 minutes to 90 minutes, so that the components can be mixed evenly.

...

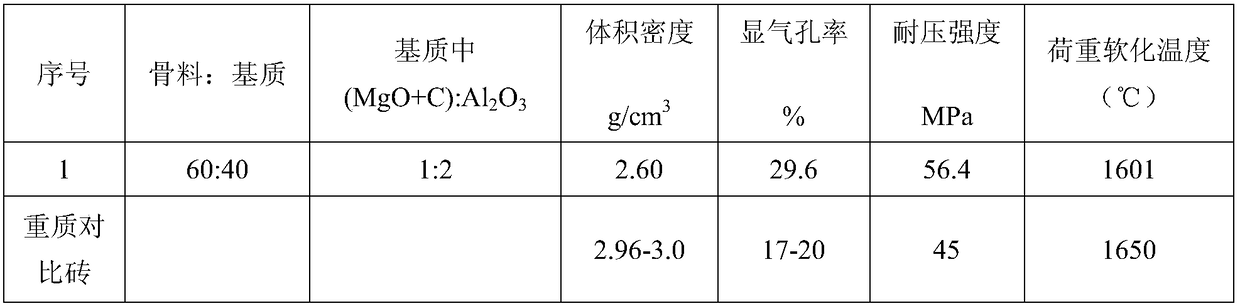

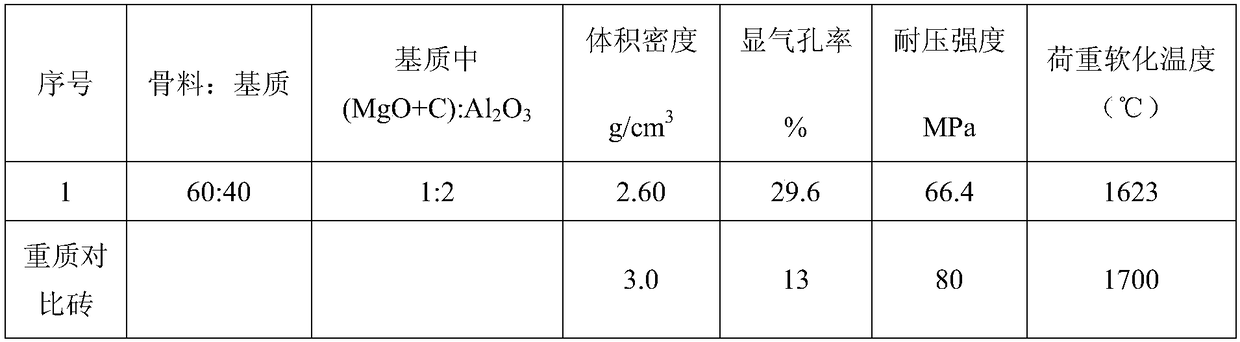

Embodiment 1

[0035]Mix 180 mesh magnesia and 180 mesh graphite evenly according to the molar ratio of MgO and C at 1:1. The tabular alumina of 1-3mm and the tabular grains of 0.1-1mm are used as coarse grains and medium grains respectively. Magnesia fine powder, graphite fine powder and alumina fine powder are used as the matrix part, and the ratio of coarse particles: medium particles: fine powder is 40:20:40. Among them, the ratio of the fine powder part of the alumina micropowder to the mixed powder of magnesium oxide and graphite is 2:1. Use phenolic resin ethylene glycol solution as a binder, and the addition amount is 8% of the total weight of the ingredients. After the ingredients are fully mixed, put them in an airtight container or plastic bag to trap the materials for 2 hours. The trapped materials are semi-dry. Molded on a hydraulic press with a molding pressure of 150MPa. The formed sample is naturally cooled for half a day to 1 day, and then dried in the drying equipment with...

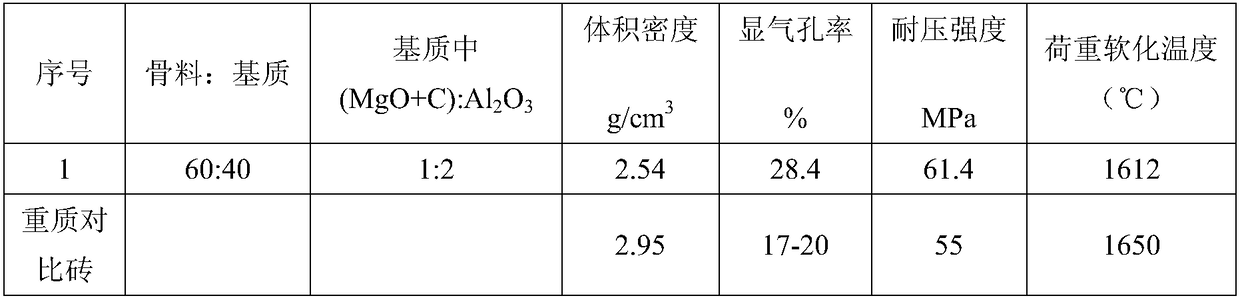

Embodiment 2

[0039] Mix 180-mesh magnesia and 180-mesh graphite according to the molar ratio of MgO and C at 1:1. The light-weight spinel particles of 1-3mm and 0.1-1mm are used as coarse particles and medium particles respectively. Magnesia fine powder, graphite fine powder and alumina fine powder are used as the matrix part, and the ratio of coarse particles: medium particles: fine powder is 40:20:40. Among them, the ratio of the fine powder part of the alumina micropowder to the mixed powder of magnesium oxide and graphite is 2:1. Use phenolic resin ethylene glycol solution as a binder, and the addition amount is 8% of the total weight of the ingredients. After the ingredients are fully mixed, put them in an airtight container or a plastic bag for 4 hours; mold them on a hydraulic press with a molding pressure of 150MPa. The good samples are naturally cooled for half a day to 1 day, and then dried in the drying equipment with staged heating and heat preservation methods, and finally ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com