A special material for fully biodegradable mulch film that is beneficial to moisture conservation and its preparation method

A technology for degrading mulch and special materials, applied in the field of polymers, can solve problems affecting crop growth and yield, affecting the promotion and application of mulch, and excessive water evaporation loss, etc., to inhibit the growth of weeds, reduce photosynthesis, and improve effective The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

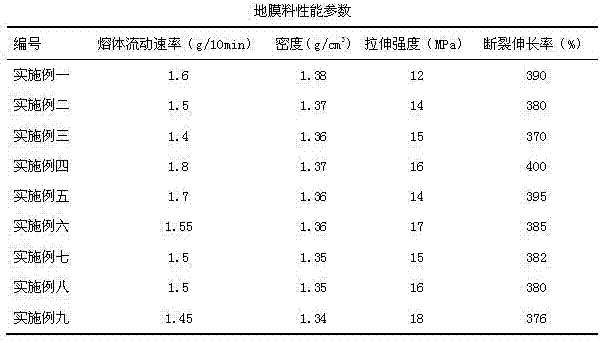

Examples

Embodiment 1

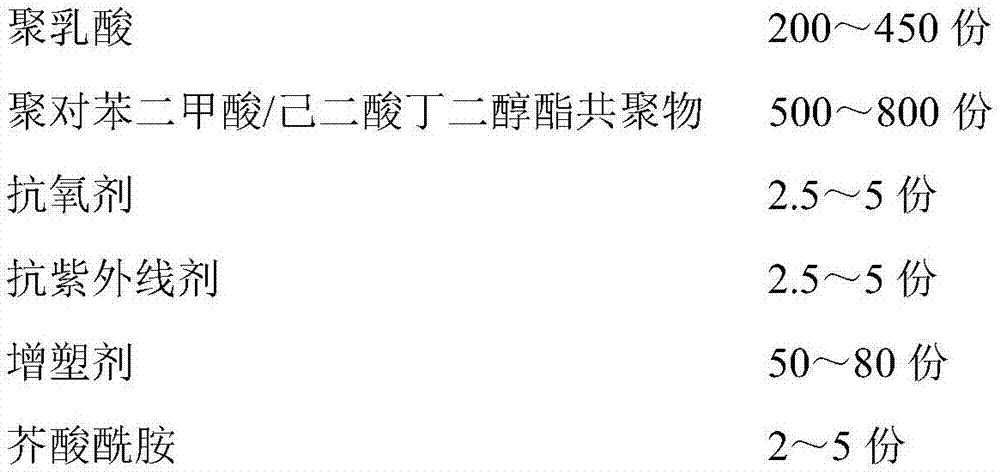

[0046] In this example, 750 parts by mass of the first component, 210 parts by mass of the second component and 20 parts by mass of the third component are used as raw materials for preparing agricultural mulch films. Wherein the preparation process of the first component is as follows:

[0047] With the polylactic acid of 200 mass parts, the polyterephthalic acid / butylene adipate copolymer of 800 mass parts, the 1010 type antioxidant of 2.5 mass parts, the UV770 type anti-ultraviolet agent of 5 mass parts, 80 mass parts Parts of tributyl citrate and 2 parts by mass of erucamide were mixed together, stirred at high speed for 10 minutes to make it evenly mixed, and the uniformly mixed material entered the twin-screw granulator, and after melting and blending in the twin-screw granulator Stranding and dicing to obtain the first component. Wherein, tributyl citrate is a plasticizer, and erucamide is an antiblocking agent. The first component reaches the head of the twin-screw g...

Embodiment 2

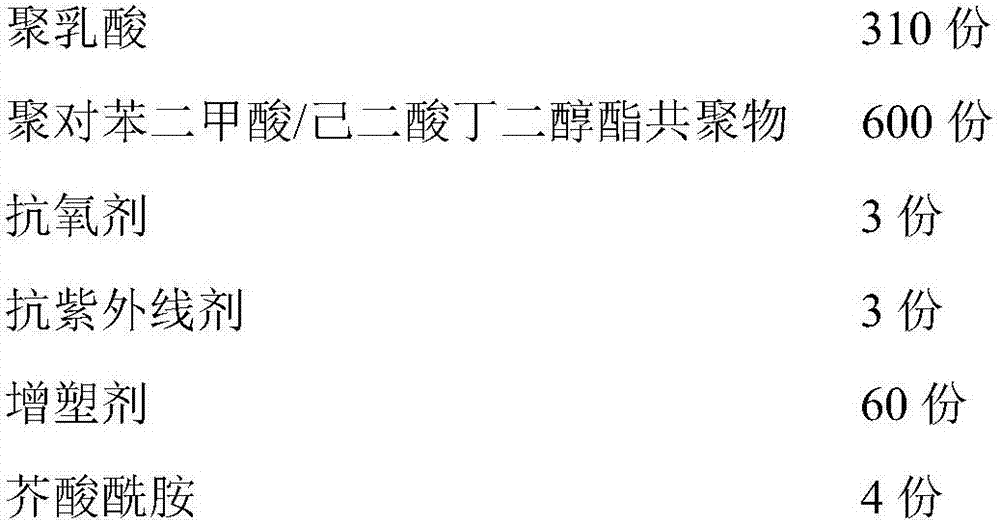

[0052] The difference between this example and Example 1 lies in that the amount of raw materials used to prepare the first component and the third component is different. Get the polylactic acid of 310 mass parts, the polyterephthalic acid / butylene adipate copolymer of 600 mass parts, the 1010 type antioxidant of 3 mass parts, the UV770 type anti-ultraviolet agent of 3 mass parts, 60 mass parts Parts of tributyl citrate and 4 parts by mass of erucamide were used as raw materials for preparing the first component.

[0053] Take 75 parts by mass of polylactic acid, 5 parts by mass of tributyl citrate and 20 parts by mass of ultrafine carbon black as raw materials for preparing the third component.

Embodiment 3

[0055] The difference between this example and Example 1 lies in that the amount of raw materials used to prepare the first component and the third component is different. Get the polylactic acid of 450 mass parts, the polyterephthalic acid / butylene adipate copolymer of 500 mass parts, the 1010 type antioxidant of 5 mass parts, the UV770 type anti-ultraviolet agent of 2.53 mass parts, 50 mass parts Parts of tributyl citrate and 5 parts by mass of erucamide were used as raw materials for preparing the first component.

[0056] Take 72 parts by mass of polylactic acid, 6 parts by mass of tributyl citrate and 22 parts by mass of ultrafine carbon black as raw materials for preparing the third component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com