High-weatherability silica gel waterproof spacer and manufacturing method thereof

A manufacturing method and technology of waterproof gaskets, applied to flat products, other household appliances, applications, etc., can solve the problems of increasing the cost of construction enterprises, and achieve the effects of excellent weather resistance, excellent strength, and high resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

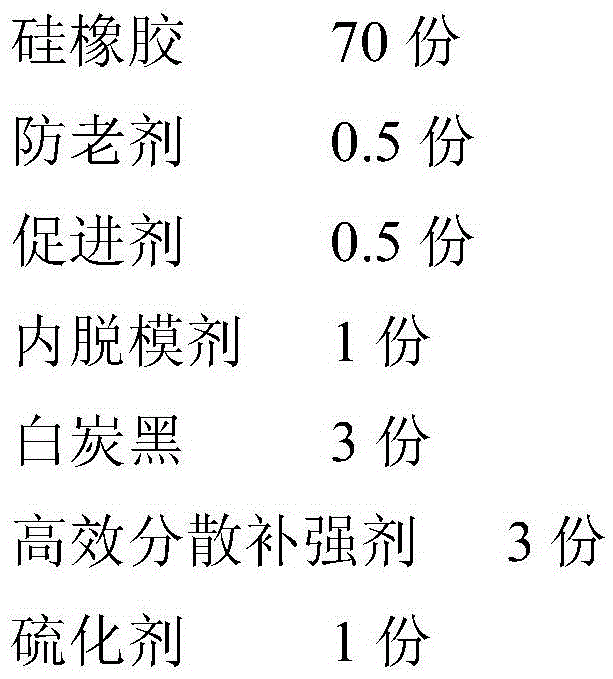

[0032] In this embodiment, the high weather resistance silicone waterproof gasket consists of the following components by weight:

[0033]

[0034] The preparation method of the above-mentioned high weather resistance silicone waterproof gasket is as follows: first mix the silicone rubber with processing aids such as anti-aging agent, accelerator, white carbon black and high-efficiency dispersion reinforcing agent, and then add a vulcanizing agent to carry out cross-linking vulcanization , forming a silicone rubber with a certain degree of crosslinking. Then add an internal release agent, and carry out a molding process under high temperature and high pressure through a mold to make a waterproof gasket. The molding temperature of the mold was 150°C.

Embodiment 2

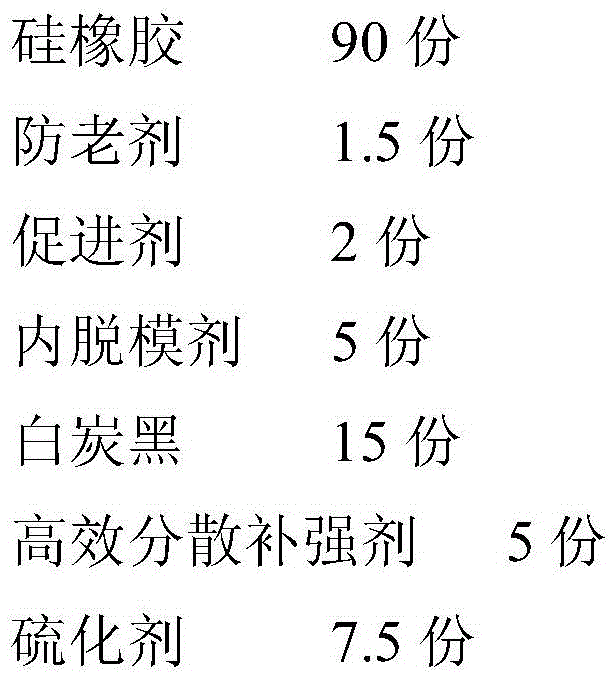

[0036] In this embodiment, the high weather resistance silicone waterproof gasket consists of the following components by weight:

[0037]

[0038] The preparation method of the above-mentioned high weather resistance silicone waterproof gasket is as follows: first mix the silicone rubber with processing aids such as anti-aging agent, accelerator, white carbon black and high-efficiency dispersion reinforcing agent, and then add a vulcanizing agent to carry out cross-linking vulcanization , forming a silicone rubber with a certain degree of crosslinking. Then add an internal release agent, and carry out a molding process under high temperature and high pressure through a mold to make a waterproof gasket. The molding temperature of the mold was 200°C.

Embodiment 3

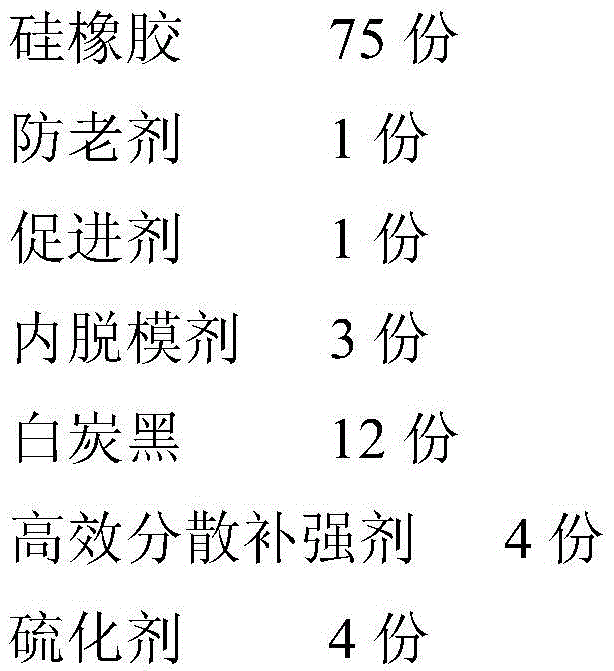

[0040] In this embodiment, the high weather resistance silicone waterproof gasket consists of the following components by weight:

[0041]

[0042] The preparation method of the above-mentioned high weather resistance silicone waterproof gasket is as follows: first mix the silicone rubber with processing aids such as anti-aging agent, accelerator, white carbon black and high-efficiency dispersion reinforcing agent, and then add a vulcanizing agent to carry out cross-linking vulcanization , forming a silicone rubber with a certain degree of crosslinking. Then add an internal release agent, and carry out a molding process under high temperature and high pressure through a mold to make a waterproof gasket. The molding temperature of the mold was 170°C.

[0043] The high weather resistance silicone waterproof gasket and its preparation method provided by the invention, compared with the traditional rubber gasket, this product has excellent strength, elongation at break, resili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com