High-solid content low-VOC high-gloss PE paint

A high-gloss, high-solids technology, applied in coatings, polyester coatings, etc., can solve the problems of poor sagging resistance of paint films, poor whitening resistance in rainy days, and low gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with embodiment.

[0015] A high-solid low-VOC high-gloss PE paint is characterized in that it consists of PE resin 8301, PE resin 988, F450PE anti-greening dispersant, AC-300 defoamer, transparent powder 1250 mesh, 800 mesh talcum powder, PLB Zinc stearate, PE paint leveling agent LP-5800, 6500 anti-settling wax slurry and silica anti-settling slurry;

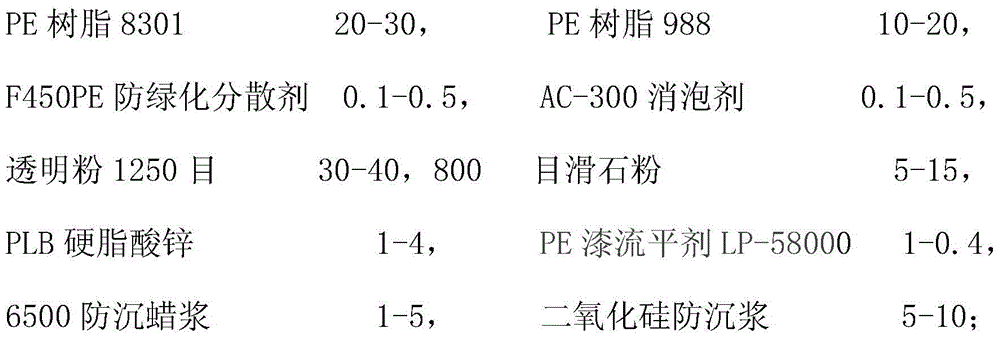

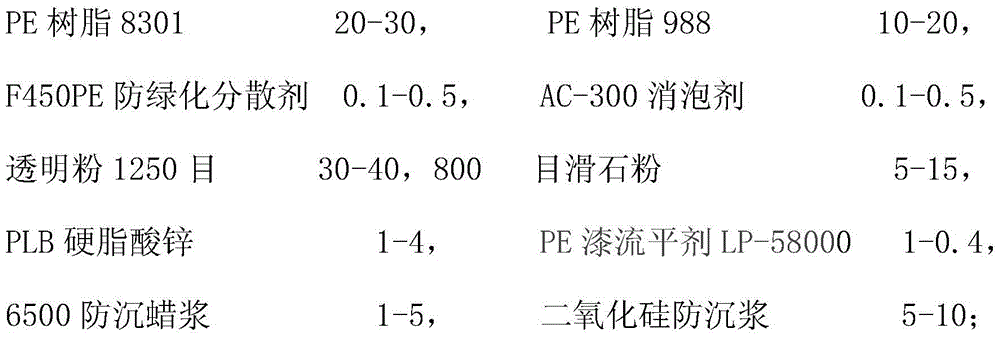

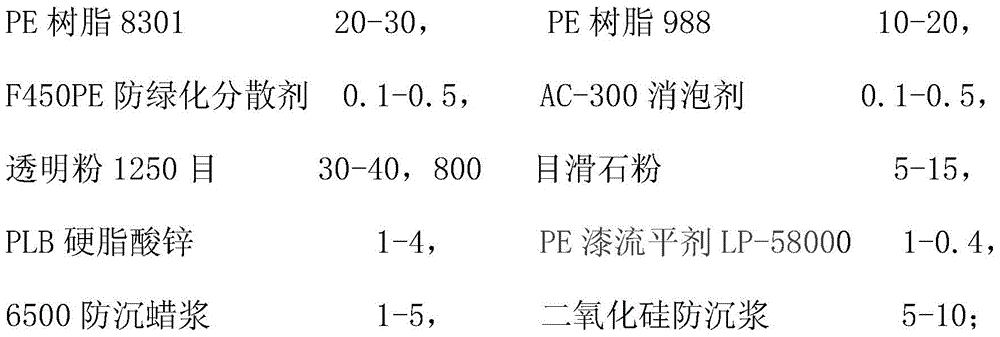

[0016] Its parts by weight ratio:

[0017]

[0018] The silica anti-settling slurry is made of PE resin 988, toluene and silica M-5.

[0019] The weight and number ratio of described silicon dioxide anti-settling slurry formula is:

[0020] PE resin 988 70-80, toluene 15-25, silica M-5 2-8.

[0021] The preparation method of the silica anti-settling slurry is as follows: add PE resin and toluene into a mixing tank, stir and add silica at a medium speed, and then disperse at a high speed for 5 minutes, and after the fineness is measured to be belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com