Flushing device with anti-sinking structure for river silt and implementation method of flushing device

A technology for river silt and anti-subsidence, applied in the direction of earth mover/shovel, construction, etc., can solve problems such as hidden safety hazards and subsidence of standing positions of personnel, and achieve the effect of expanding the scour range and good anti-subsidence effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

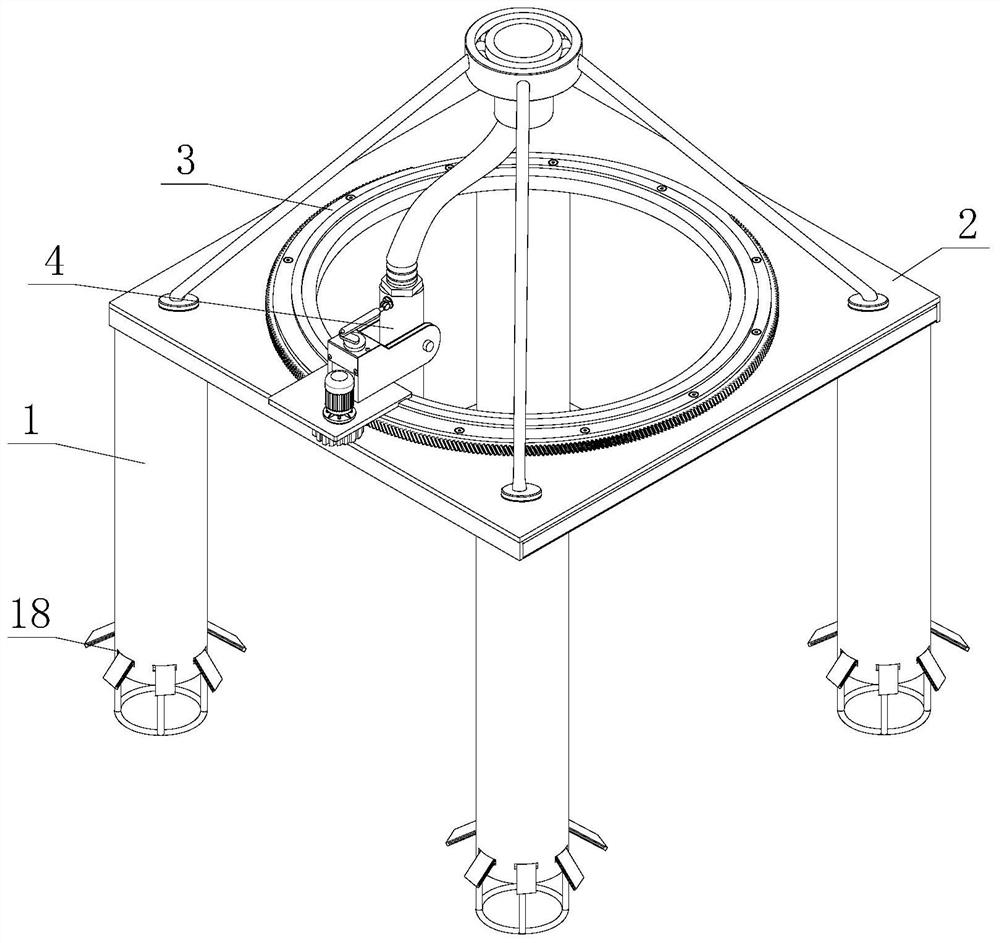

[0040] In order to better demonstrate the implementation process of the scouring device with the anti-subsidence structure for the river silt, this embodiment now proposes an implementation method for the scouring device with the anti-subsidence structure for the river silt, including the following steps:

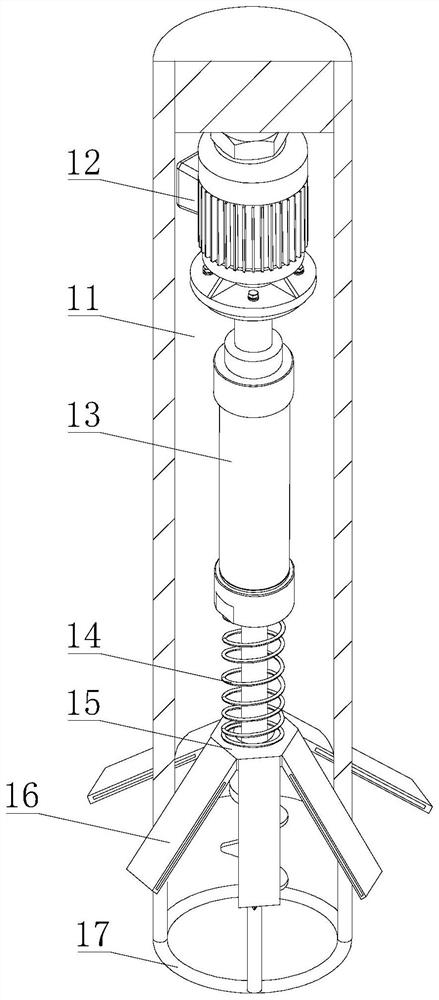

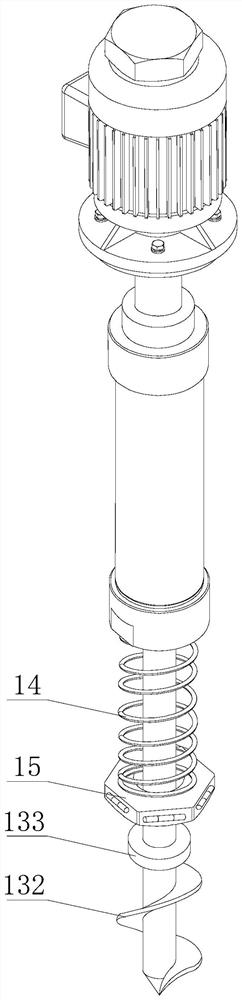

[0041] Step 1: Place the flushing device as a whole within the range of the cofferdam for the river channel. The steel ring 17 is in contact with the surface of the mud. Under the action of its own weight, the whole flushing device sinks slightly, and the steel ring 17 is buried in the mud. , the steel ring 17 supports the flushing device, and the threaded drill bit 132 is accommodated in the hollow groove 11. At the same time, the limit block 133 squeezes the push plate 15 under the action of the telescopic cylinder 13, and the support spring 14 shrinks, and the push plate 15 Moving up drives one end of the anti-sinking plate 16 to move upwards, so that the anti-sinking pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com