An improved high-efficiency high-temperature environmental protection carbonization and gasification furnace

A gasification furnace and carbonization technology, which is applied in the field of high-efficiency high-temperature environmental protection carbonization and gasification furnace, can solve the problems of incombustible gas, tar and biological extract, heat energy recovery and utilization, etc., to achieve intensive use, improve carbonization efficiency and Cooling efficiency, energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

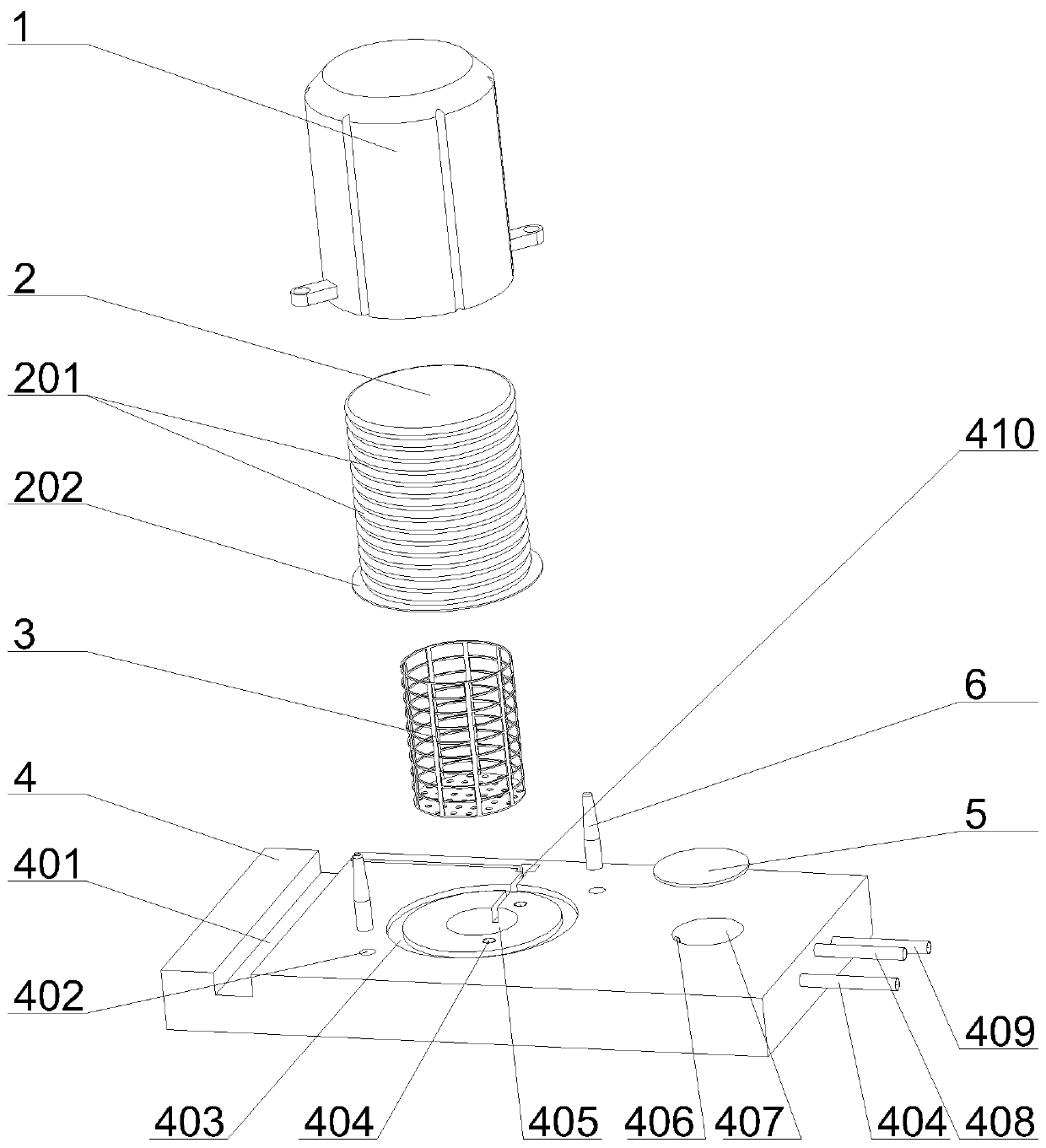

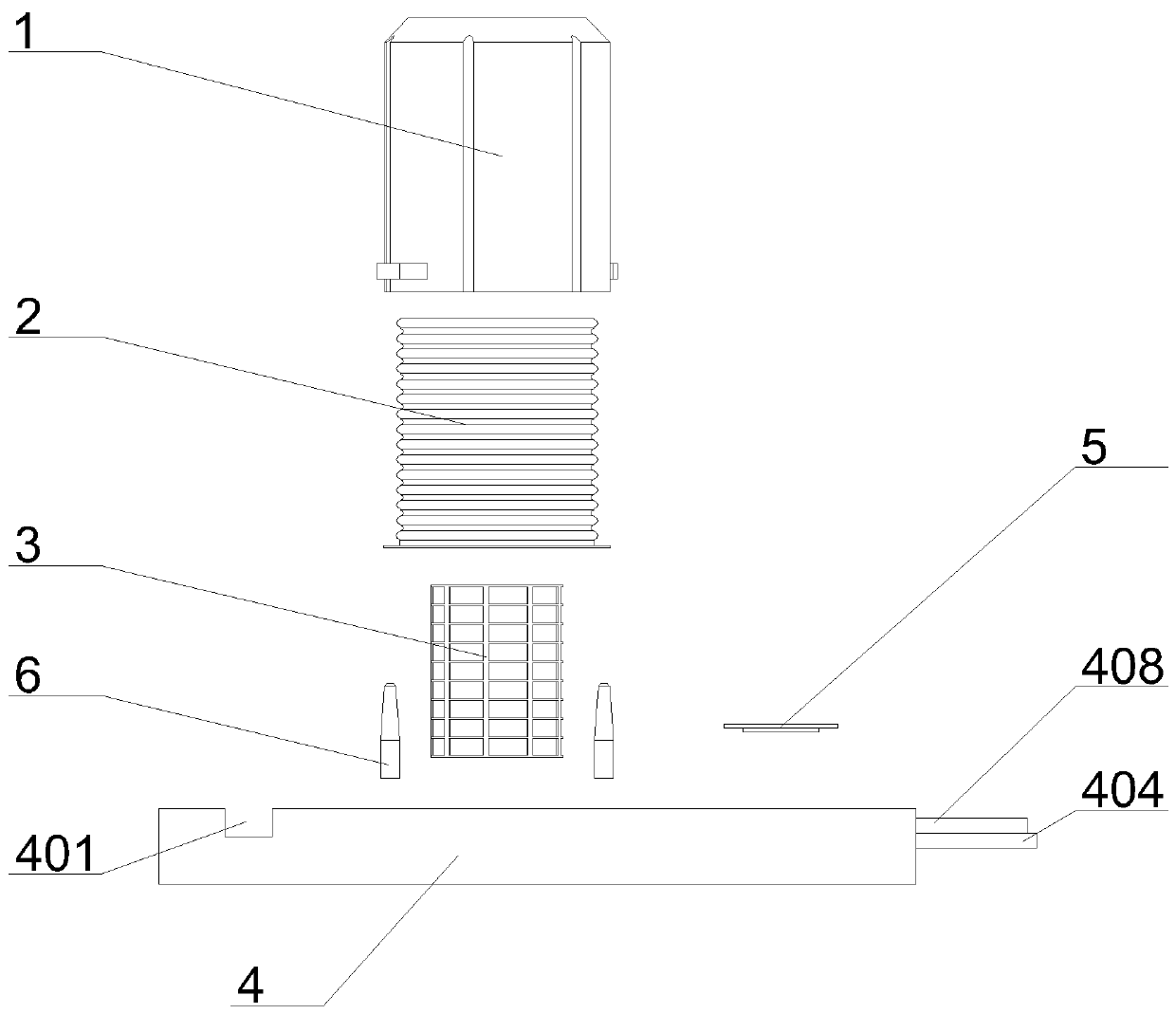

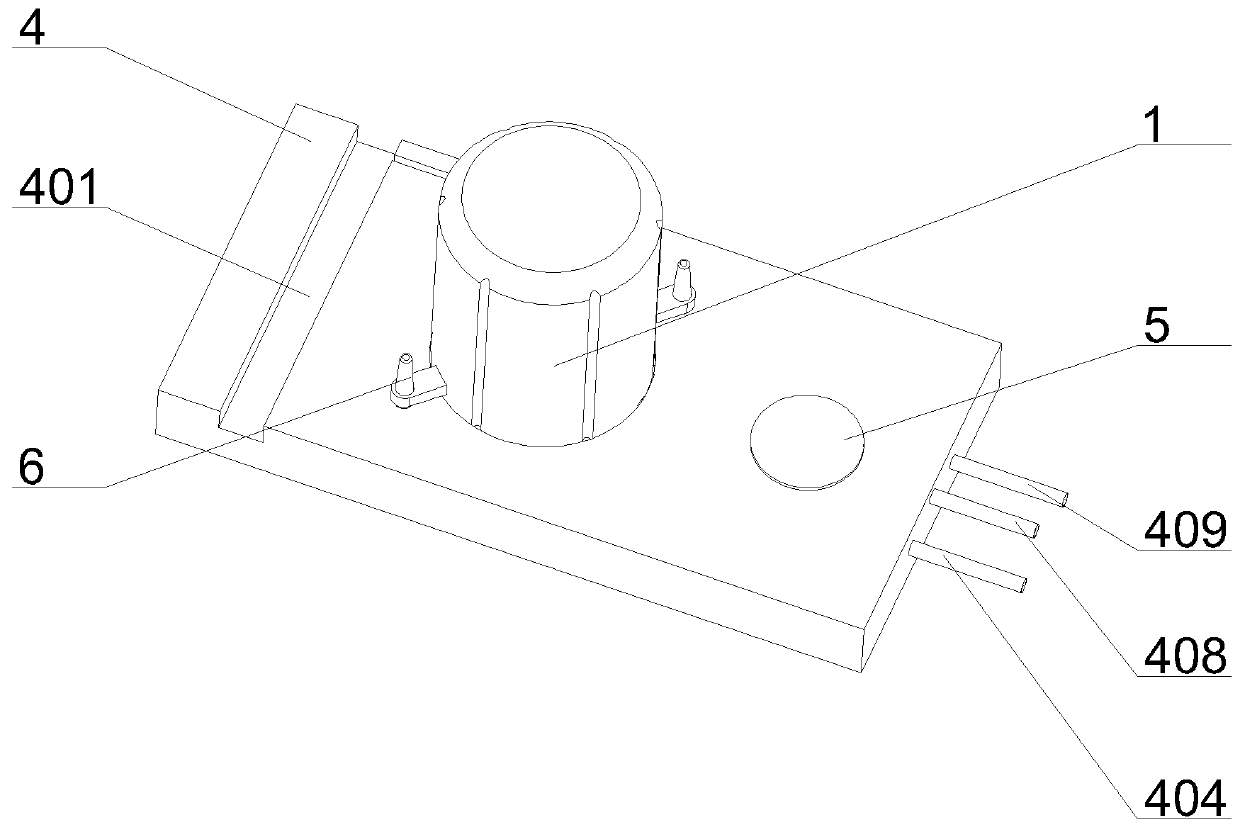

[0026] Example: such as Figure 1 to Figure 9 As shown, the carbonization furnace is composed of a furnace cover 1, an inner cover 2, a material frame 3, a furnace base 4, a sealing cover 5, a positioning rod 6, a temperature control device, a control device, a thermocouple, and a cooling cover, wherein the furnace base 4 It consists of a cable groove 401, a positioning rod installation base 402, a sealing groove 403, a cooling and heating inlet pipe 404, an inner smoke well 405, a flue gas communication pipe 406, an outer smoke well 407, a flue gas discharge pipe 408, a cooling and heating outlet pipe 409, and a thermoelectric Couple installation groove 410, liquid communication pipe 411, cable groove 401, positioning rod installation base 402, sealing groove 403, inner smoke well 405, outer smoke well 407, thermocouple installation groove 410 are located on the surface of the furnace base 4, cooling and heating intake pipe 404, the flue gas communication pipe 406, the flue g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com