Open-width washing equipment and method of use thereof

A technology for washing water and equipment, applied in the field of open-width washing equipment, can solve the problems of not meeting the requirements of environmental protection and energy saving, consuming manpower and time, and large volume of dyeing tanks, so as to avoid large changes in solution concentration, reduce investment, and improve cleaning. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

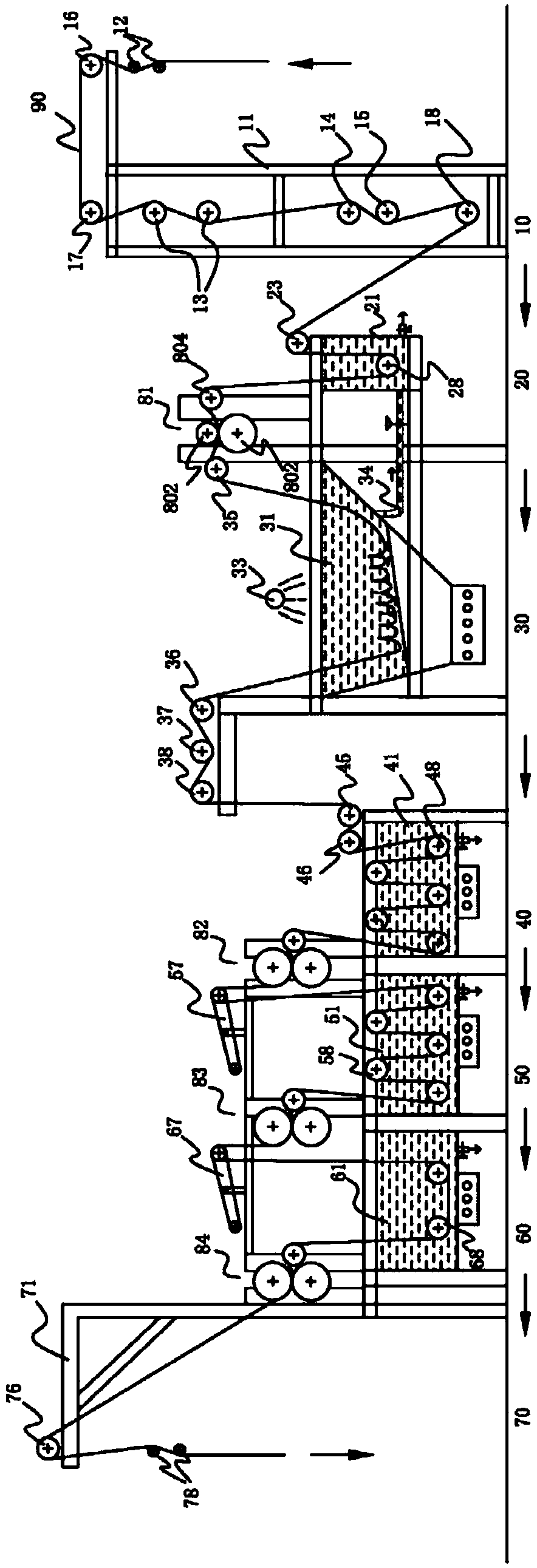

[0019] like figure 1 As shown, the open-width washing equipment of the present invention includes a centering and upper cloth mechanism 10, a pre-wet tank 20, a soda boiling tank 30, a cleaning tank 40, a peracid tank 50, a softening tank 60 and a cloth collecting mechanism 70. And between the pre-wet tank 20 and the caustic soda tank 30, between the cleaning tank 40 and the peracid tank 50, between the peracid tank 50 and the softening tank 60, between the softening tank 60 and the cloth collecting mechanism 70, respectively set There is a dehydration mechanism.

[0020] Specifically, the centering and loading mechanism 10 includes an upper fabric support 11, a set of tension adjustment rollers 12 erected on the upper fabric support 11, a set of centering rollers 13, two edge rollers and a plurality of fabric guide rollers. . The upper cloth support 11 is divided into upper and lower layers, and the top of the upper layer extends outwards to form a platform. The set of ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com