Waste gas biological treatment device and control method thereof

A biological treatment and exhaust gas technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as unstable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

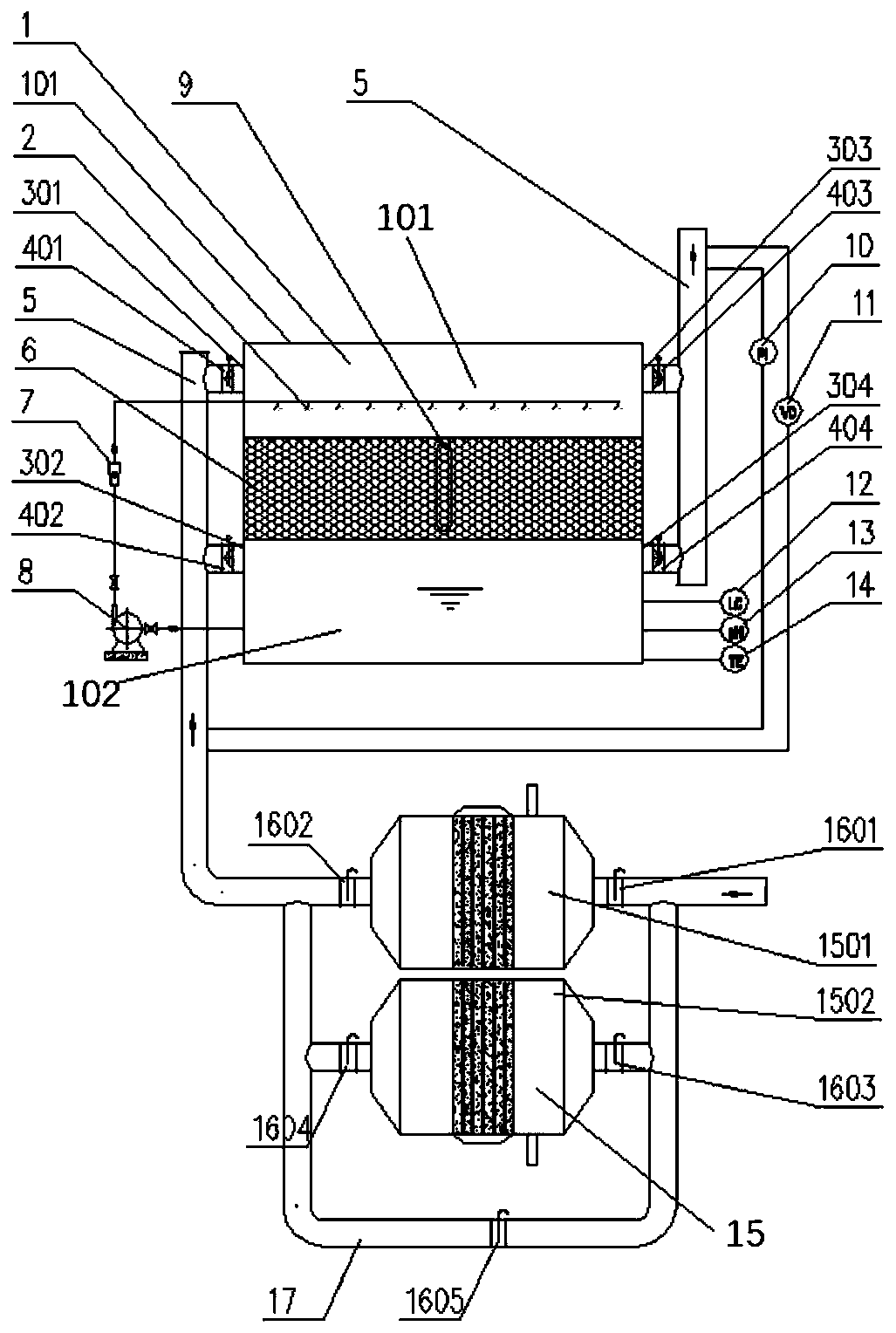

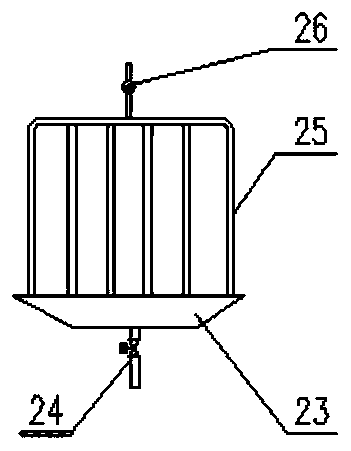

Embodiment 1

[0053] combine Figure 1-3 A waste gas biological treatment device proposed in this embodiment includes a biological filter tower 1 and a buffer unit. The biological filter tower 1 is provided with an air inlet and an air outlet, and the air outlet and the air inlet are connected to the first The two waste gas pipes are communicated, and the gas outlet is also communicated with the opening and the exhaust gas discharge port. The biological filter tower 1 is provided with a first chamber 101, a packed bed 6 and a second chamber 102, and the packed bed 6 is located in the first chamber. Between the chamber 101 and the second chamber 102, the first chamber 101 and the second chamber 102 are communicated through water pipes, and the buffer unit includes at least two buffer tanks 15 with adsorption and desorption functions, and for Across the bypass air pipe 17 of the buffer tank 15, one end of the two buffer tanks 15 is connected to the first exhaust gas pipe, and the other end of...

Embodiment 2

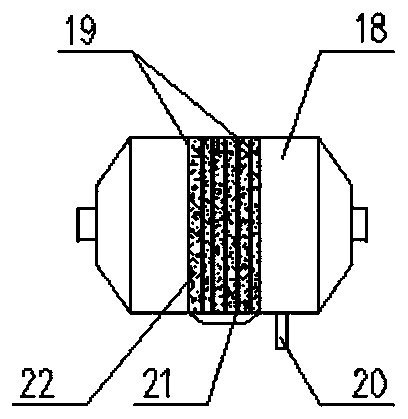

[0056] combine Figure 1-3, a kind of waste gas biological treatment device that present embodiment proposes, on the basis of embodiment 1, can make following improvement: described buffer tank 15 is provided with adsorbent bed 22, and described adsorbent bed 22 is provided with temperature control The device 20 and the heating device 21 are both connected to the controller. The heating device 21 is used to heat the adsorbent bed 22, which can be controlled by the controller to heat the adsorbent bed 22 according to the needs of the working conditions, thereby desorbing; the temperature control device 20 is used to detect the temperature of the adsorbent bed 22, which is controlled by the controller , so that the temperature of the adsorbent bed 22 is lower than 120° C., so as to realize the homogenization effect of the waste gas passing through the buffer tank 15 . The bypass air pipe 17 is provided with a ventilation valve 1605. When there are two buffer tanks 15, the first...

Embodiment 3

[0058] combine Figure 1-3 , a waste gas biological treatment device proposed in this embodiment, on the basis of Embodiment 1 or 2, the following improvements can be made: the packing bed 6 of the biological filter tower 1 is provided with a sight glass 9 . Observe the shape of the filler biofilm with the naked eye, and judge the quantity of the biofilm qualitatively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Packing density | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com