High-pressure gear oil pump

A gear oil pump, high-pressure technology, applied in lubrication pumps, engine components, engine lubrication, etc., can solve problems such as large overlap coefficient and backlash, low volumetric efficiency, and heat generation of hydraulic oil, and reduce sliding coefficient and contact stress , Improve volumetric efficiency and reduce leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

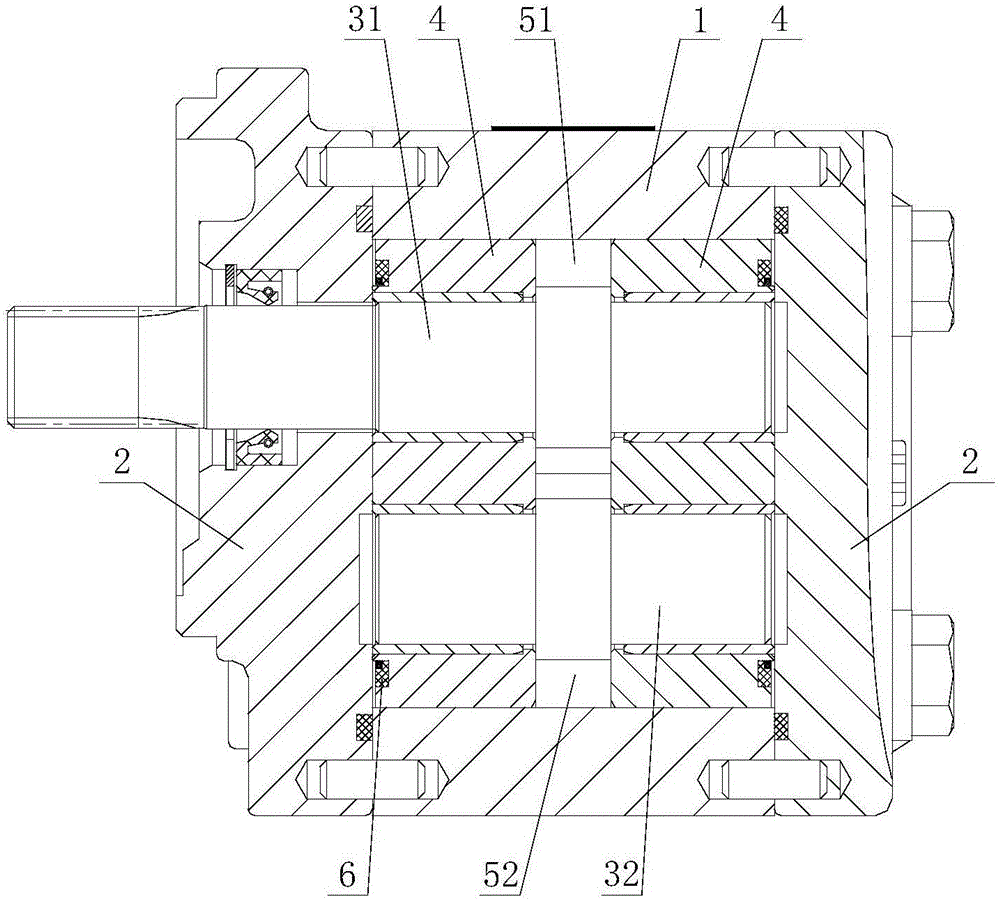

[0020] see figure 1

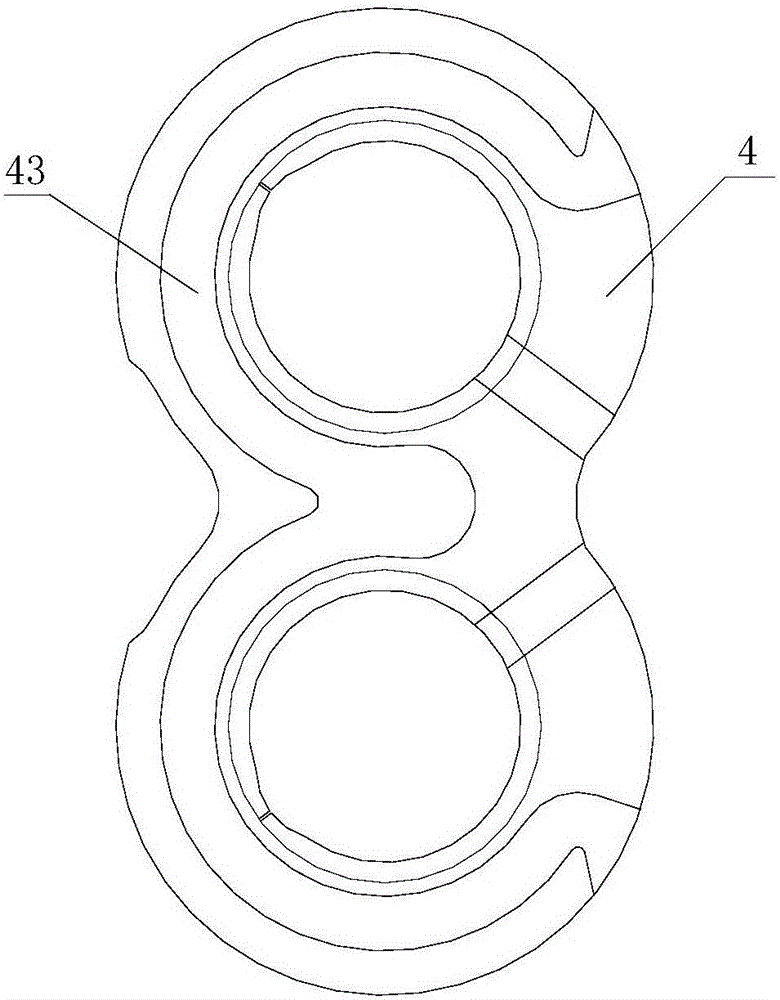

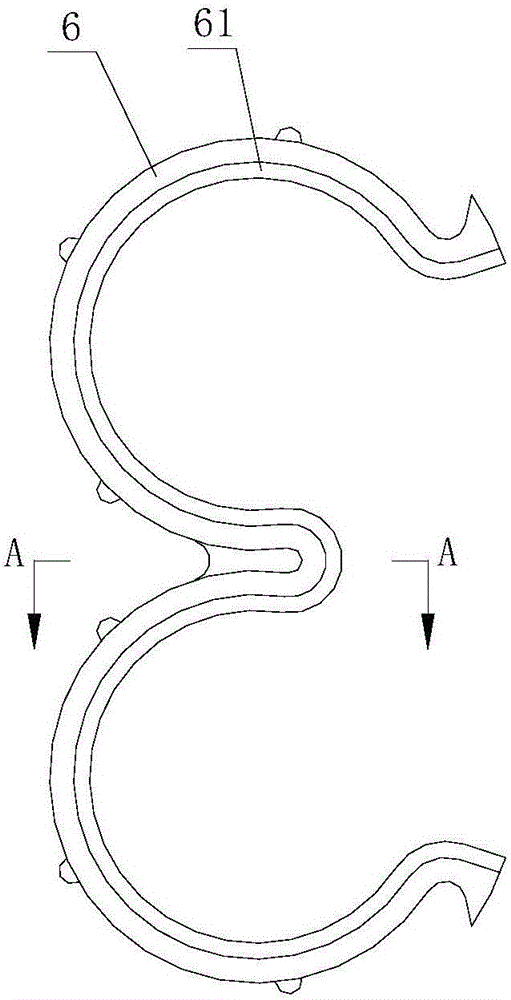

[0021] The high-pressure gear oil pump of the present invention comprises a pump body 1, two end covers 2 respectively arranged at both ends of the pump body 1, and a driving gear shaft 31 and a driven gear shaft 32 arranged in the pump body 1, the driving gear shaft 31 A driving gear 51 is arranged on it, and a driven gear 52 is arranged on the driven gear shaft 32. The driving gear 51 and the driven gear 52 form a meshing transmission, and it is characterized in that: the driving gear 51 and the driven gear 52 The gear parameters are: pressure angle 28°, center distance 33mm, 3.25 modulus 10 teeth.

[0022] The present invention makes the above-mentioned improvements to the gears of the gear oil pump, which can effectively reduce the overlapping coefficient of the gears, and automatically adjust the radial clearance of the gears and the clearance a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com