Food processing device capable of increasing heat utilization rate

A technology of food processing equipment and utilization rate, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of not complying with energy saving and consumption reduction, unutilized, etc., to achieve a large space occupation, reduce heat loss, and cost. high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

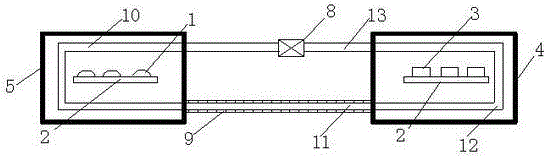

[0022] In this embodiment, a food processing device that improves heat utilization, such as figure 1 As shown, it includes a cooling box 5 and a heating box 4, and the inside of the cooling box 5 and the heating box 4 are respectively provided with a first heat exchange tube 10 and a second heat exchange tube 12; also includes a first connecting tube 11 and a second connecting tube Pipe 13, the water outlet of the first heat exchange tube 10 and the water inlet of the second heat exchange tube 12 are connected by the first heat exchange tube 10, the water inlet of the first heat exchange tube 10 and the water inlet of the second heat exchange tube The water outlet of 12 is communicated by the second connecting pipe 13; the first heat exchange pipe 10, the second heat exchange pipe 12, the first connecting pipe 11, and the second connecting pipe 13 form a closed loop, and a circulation is provided in the closed loop pump 8; also includes a conveyor belt 2, which passes through ...

Embodiment 2

[0026] In this embodiment, the first connecting pipe 11 is a plastic pipe with a rough inner wall, and the outer wall is provided with an insulating layer 9. The first connecting pipe flows through the heated water that has just flowed out from the outlet of the first heat exchange pipe. An insulation layer is arranged outside the first connecting pipe, which can inhibit the heat exchange between hot water and air during the flow, and reduce heat loss. The first connecting pipe is a plastic pipe with a rough inner wall, and its inner diameter is smaller than that of the first exchange pipe The small inner diameter of the heat pipe can increase the degree of turbulence of the water in the pipe, so that the water can also obtain more heat during the flow.

Embodiment 3

[0028] In this embodiment, the second connecting pipe 13 is made of metal, its wall thickness is 2mm-5mm, and its inner diameter is larger than the inner diameter of the second heat exchange pipe 12, and the metal material is more conducive to heat exchange. Insufficient heat exchange is caused, and the tube wall is too thin, which will cause the problem that the tube is easily damaged due to low strength. The selected tube wall thickness is 2mm-5mm, which can simultaneously overcome the problems of insufficient heat exchange and easy damage due to too thin tube wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com