Method for evaluating after-reaction strength of metallurgical coke

A technology of post-reaction strength, metallurgical coke, applied in the direction of applying stable tension/pressure to test the strength of materials, weighing by removing certain components, etc., can solve the problem of increasing production costs, coke gap, inaccurate coke quality standards, etc. problems, to reduce the cost of coal blending, reduce the cost of molten iron, and improve the quality of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

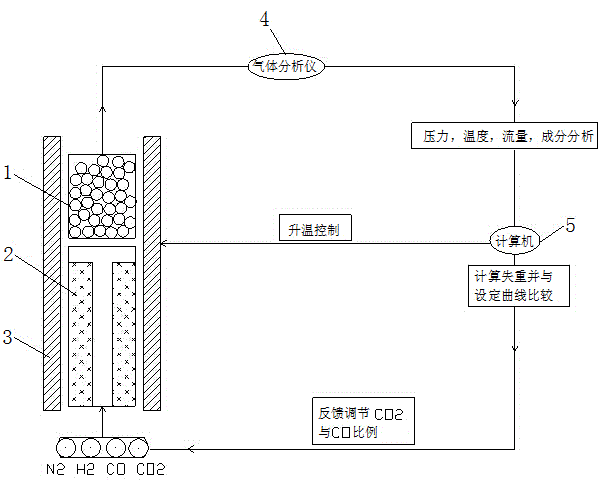

Image

Examples

Embodiment 1

[0026] To carry out a certain type of metallurgical coking coal blending, the coke obtained by using an Australian first-class coking coal and second-class coking coal in the proportion of 5% in the coal blending,

[0027] According to the national standard GB / T4000-2008, the coke reactivity CRI of the first-class coking coal blending coal is 27, and the post-reaction strength CSR is 59; the coke reactivity CRI of the second-class coking coal blending coal is 27.5, and the post-reaction strength CSR is 58.2 , the reactivity of the coke prepared from the second-class coking coal is 0.5% higher than that of the first-class coking coal, and the strength after the reaction is reduced by 0.8%. More coke increases the amount of coke used per ton of steel, causing unnecessary waste and increasing smelting costs;

[0028] The method of the present invention is used to detect that the coke strength after the reaction of the first-class coking coal blending coal is 70.2%, and the reacti...

Embodiment 2

[0031] To carry out a certain type of metallurgical coking coal blending, the coke obtained by using an Australian first-class coking coal and second-class coking coal in the coal blending ratio of 10%,

[0032] According to the national standard GB / T4000-2008, the coke reactivity CRI of the first-class coking coal blending coal is 27.5, and the post-reaction strength CSR is 60; the coke reactivity CRI of the second-class coking coal blending coal is 28.5, and the post-reaction strength CSR is 58.5 , the reactivity of the coke prepared from the second-class coking coal is 1.0% higher than that of the first-class coking coal, and the strength after the reaction is reduced by 1.5%. More coke increases the amount of coke used per ton of steel, causing unnecessary waste and increasing smelting costs;

[0033] The method of the present invention is used to detect that the coke strength after the reaction of the first-class coking coal blending coal is 70.2%, and the reaction streng...

Embodiment 3

[0036] For a certain type of iron and steel smelting coal blending, the coke obtained by using an Australian first-class coking coal and second-class coking coal in the coal blending ratio of 15% is used.

[0037] According to the national standard GB / T4000-2008, the coke reactivity CRI of the first-class coking coal blending coal is 28, and the post-reaction strength CSR is 61; the coke reactivity CRI of the second-class coking coal blending coal is 29.6, and the post-reaction strength CSR is 58.6 , the reactivity of the coke prepared from the second-class coking coal is 1.6% higher than that of the first-class coking coal, and the strength after the reaction is reduced by 2.4%; More coke increases the amount of coke used per ton of steel, causing unnecessary waste and increasing smelting costs;

[0038] The method of the present invention is used to detect that the coke strength after the reaction of the first-class coking coal blending coal is 70.2%, and the reaction streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com