Machine tool cutting amount energy consumption optimization method based on adaptive genetic algorithm

A technology of genetic algorithm and optimization method, applied in genetic rules, data processing applications, calculations, etc., can solve problems such as low energy utilization efficiency of machine tools and large energy saving potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

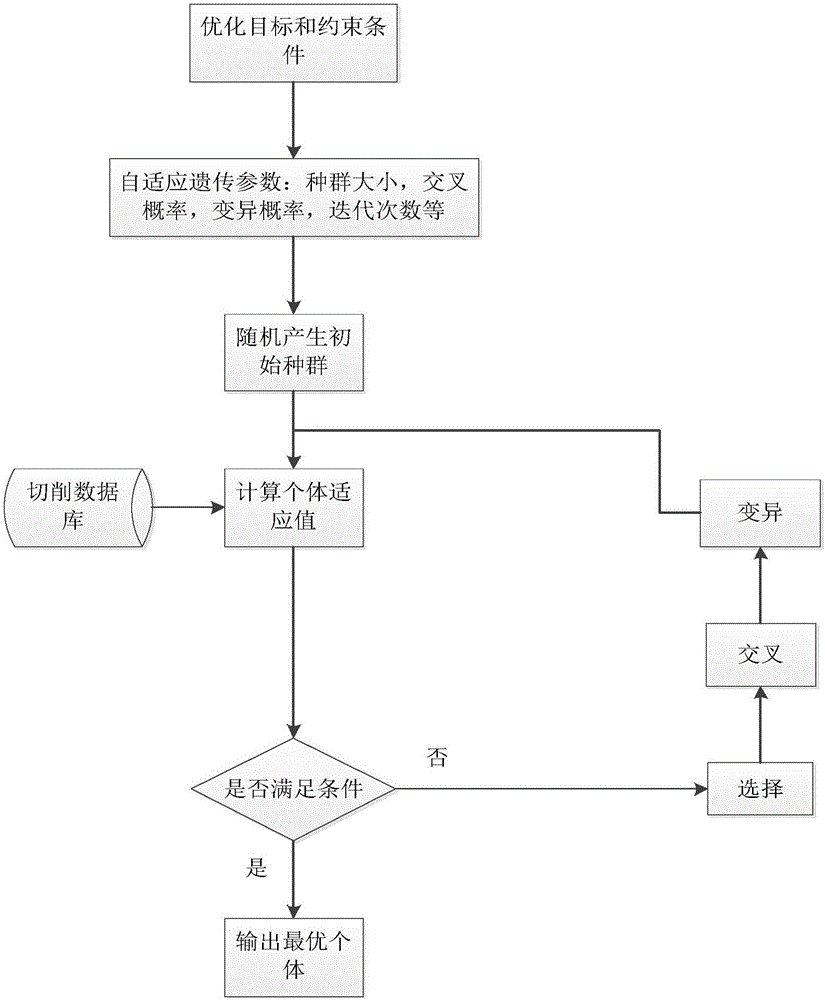

[0057] The present invention will be further described below in conjunction with drawings and embodiments. Concrete implementation steps of the present invention are as follows:

[0058] (1) Determine the model optimization variables.

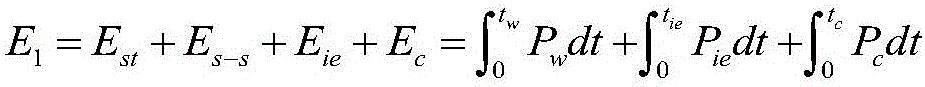

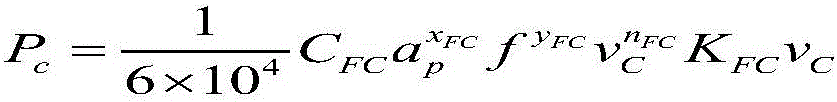

[0059] In the optimization design, its essence is to make the target to be optimized reach the optimum by changing the design variables. In the cutting optimization mathematical model, three elements of cutting processing: cutting speed v c , Feed amount f, back cutting amount a p These are the three most active and independent variables that affect carbon emissions and energy consumption during processing. Since in NC programming a p is determined by the user according to the machining allowance, v c It is determined by the spindle speed n and the cutting diameter. However, n and f are generally recommended by the system or determined by the user based on experience and cutting manuals. Therefore, a p It can be determined by the user a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com