Easily assembled self-supporting cable

An easy-to-assemble, self-supporting technology, applied in the direction of power cables, power cables, insulated cables, etc. for overhead applications, can solve the problems of low yield of finished products, bulky cables, troublesome cable manufacturing, etc., and achieve the yield of finished products High, flexible cable capacity, the effect of cable capacity expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

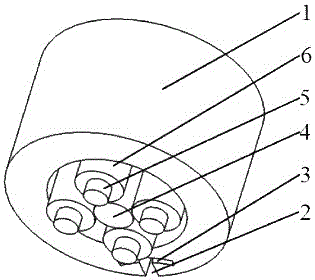

[0030] see Figure 1 to Figure 4 , an easy-to-assemble self-supporting cable, which is composed of a cable part and a hanging wire part, the cable part includes a cable core, a sheath layer 1 located outside the cable core, and the cable core contains four power transmission Conductor; the suspension wire part includes a tensile element 11 and a suspension wire sheath 12 extruded and wrapped outside the tensile element; it is characterized in that the cable part and the suspension wire part are independent of each other, and the sheath layer has a composite groove, the composite groove The slot is composed of a vertical slot 2 and a horizontal slot 3. One end of the vertical slot penetrates to the edge of the sheath layer, and the horizontal slot is located at the other end of the vertical slot. In any cross section, the axis of the vertical slot passes through the center of the cable part, and the horizontal slot is located at the center of the cable part. The axis of the ver...

Embodiment 2

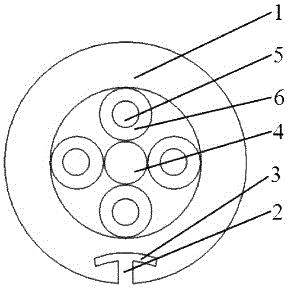

[0032] see Figure 5 , and refer to figure 1 , figure 2 and Figure 4, an easy-to-assemble self-supporting cable, which is composed of a cable part and a hanging wire part, the cable part includes a cable core, a sheath layer 1 located outside the cable core, and the cable core contains four power transmission Conductor; the suspension wire part includes a tensile element 11 and a suspension wire sheath 12 extruded and wrapped outside the tensile element; it is characterized in that the cable part and the suspension wire part are independent of each other, and the sheath layer has a composite groove, the composite groove The slot is composed of a vertical slot 2 and a horizontal slot 3. One end of the vertical slot penetrates to the edge of the sheath layer, and the horizontal slot is located at the other end of the vertical slot. In any cross section, the axis of the vertical slot passes through the center of the cable part, and the horizontal slot is located at the center...

Embodiment 3

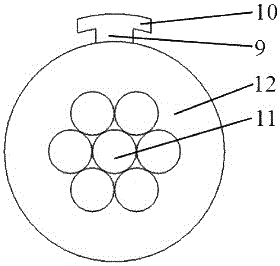

[0034] See Image 6 and Figure 7 , and refer to figure 1 , figure 2 and Figure 4 , an easy-to-assemble self-supporting cable, which is composed of a cable part and a hanging wire part, the cable part includes a cable core, a sheath layer 1 located outside the cable core, and the cable core contains four power transmission Conductor; the suspension wire part includes a tensile element 11 and a suspension wire sheath 12 extruded and wrapped outside the tensile element; it is characterized in that the cable part and the suspension wire part are independent of each other, and the sheath layer has a composite groove, the composite groove The slot is composed of a vertical slot 2 and a horizontal slot 3. One end of the vertical slot penetrates to the edge of the sheath layer, and the horizontal slot is located at the other end of the vertical slot. In any cross section, the axis of the vertical slot passes through the center of the cable part, and the horizontal slot is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com