Micro-channel structure and micro-fluid chip for achieving two-dimensional fluid power accumulation by using single-way sheath liquid

A technology of fluid dynamics and micro-channels, which is applied in the direction of laboratory containers, laboratory utensils, chemical instruments and methods, etc., which can solve the problems of reducing detection accuracy and stability, small cross-section, and inability to realize high-speed detection of biological particles, etc. problem, to achieve the effect of ensuring the two-dimensional focusing effect and maintaining the stability of the liquid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

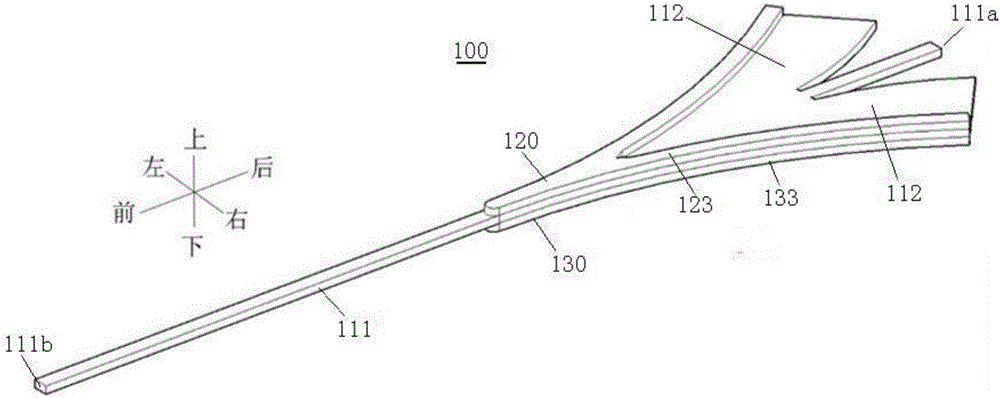

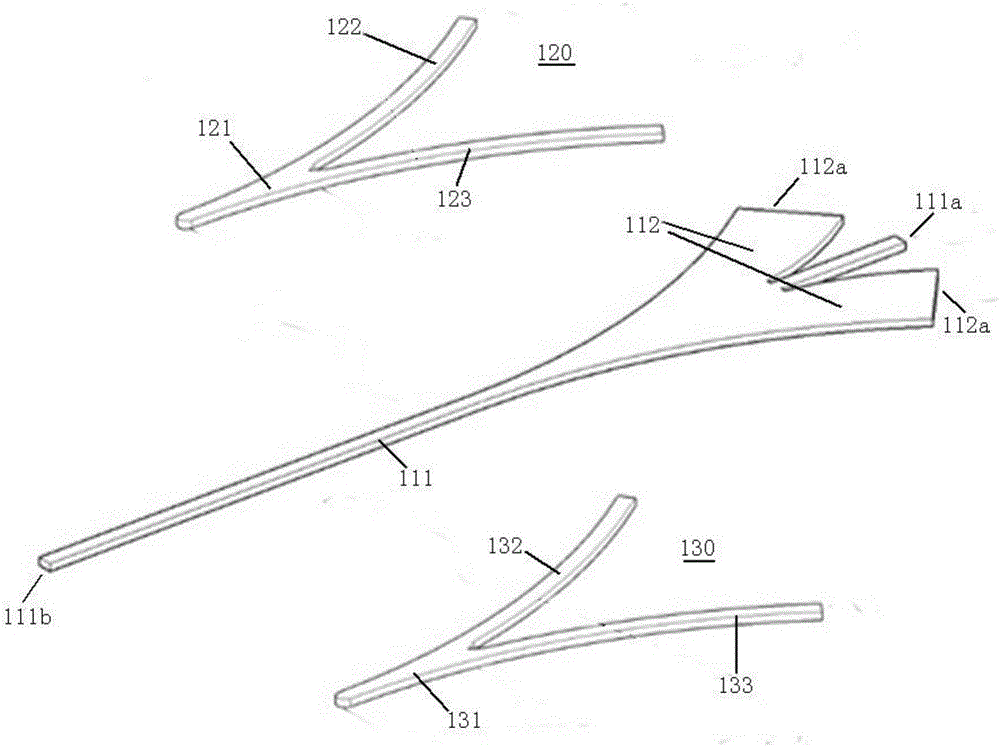

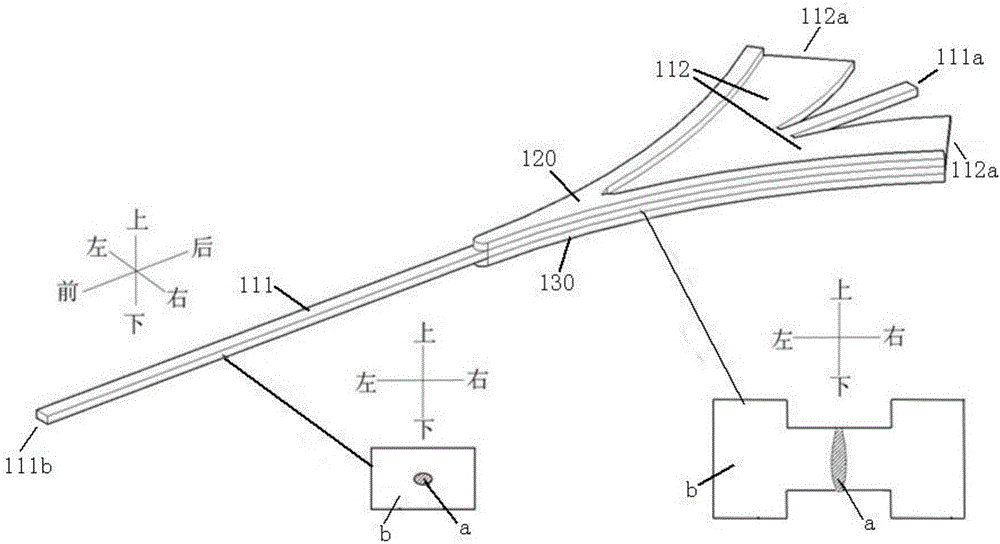

[0082] The first layer of micro-channels and the third layer of micro-channels communicate with the second layer of micro-channels and have the same outer profile to ensure that the pressure of the sheath fluid flow b therein is the same as that of the liquid in the second-layer micro-channels. The flow pressure changes synchronously and maintains the stability of the liquid flow in the system; the two arcs in the first layer of microchannels (the upper longitudinal focused flow channel 120) or the third layer of microchannels (the lower longitudinal focused flow channel 130) The flow channel profile at the intersection of the micro-channel (the left arc channel part 122 (132) and the right arc channel part 123 (133)) needs to maintain an appropriate length L in the front and rear directions, and the length will increase if the length is too long. The sheath liquid flow b in the first layer of microchannels and the third layer of microchannels squeezes the sample flow a lateral...

Embodiment 2

[0089] In this embodiment, the heights of the first layer of microchannels and the third layer of microchannels are equal to meet the requirement of focusing the sample flow a at the vertical center. The height of the second layer of microchannels can be different from the heights of the first layer and the third layer of microchannels, keeping the height of the second layer of microchannels unchanged, by increasing or decreasing the first layer of microchannels and the second layer of microchannels at the same time The height of the three-layer microchannel can increase or decrease the flow rate of the sheath fluid b in the two-layer microchannel, thereby enhancing or weakening the longitudinal focusing effect on the sample flow a (correspondingly weakening and then strengthening the lateral focus on the sample flow a focus effect).

[0090] Specifically, the height of the second layer of microchannels in this embodiment is 150 μm, the heights of the first layer and the third...

Embodiment 3

[0096] Such as Figure 7 As shown, in this embodiment, the flow rate of sample flow a is 1 μL / s, and the flow rate of sheath fluid b is 120 μL / s. After focusing, the flow velocity of sample flow a reaches 5.1 m / s, and sample flow a is located in the center of the flow channel. The front end surface of the straight channel portion 121 ( 131 ) is a micro-channel structure 100 with a flat, angled or arc-shaped surface, and other dimensions are the same as those of the micro-channel structure 100 in Embodiment 1.

[0097] When the front end of the linear channel part 121 (131) adopts a flat surface, the sheath liquid flow b in the first layer of microchannels and the third layer of microchannels has a limited longitudinal focusing effect on the sample flow a, and the focused sample flow a The cross-sectional shape is approximately a rectangle of 6 μm×50 μm (width×height).

[0098] When the front end surface of the straight channel part 121 (131) adopts an angled surface, the shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com