Light-cured three-dimensional printer laser scanning path

A laser scanning path, 3D printer technology, applied in the direction of additive processing, etc., can solve the problems of reducing the printing accuracy and surface finish, and the surface finish cannot meet the accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

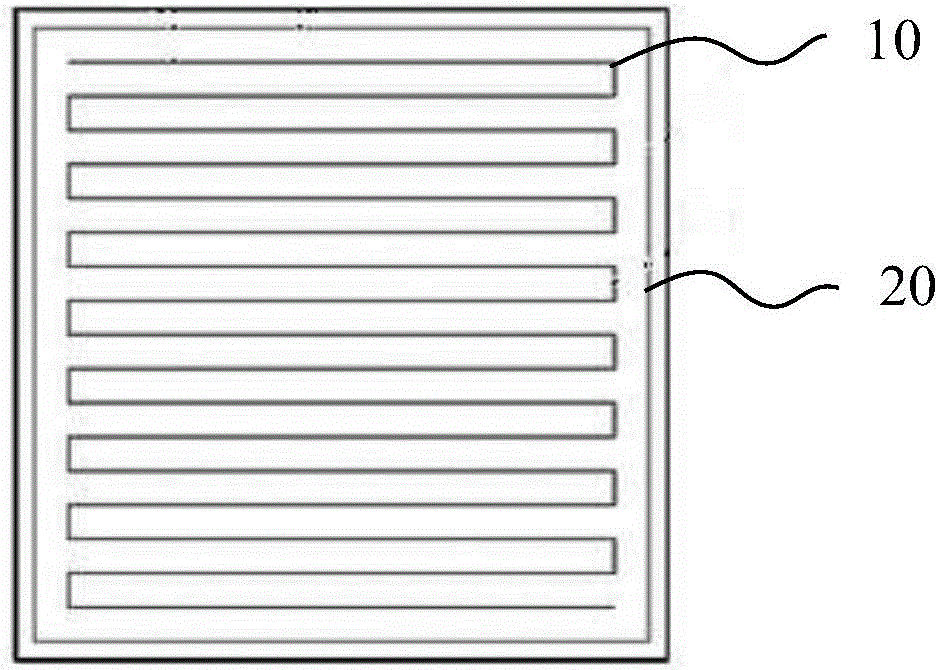

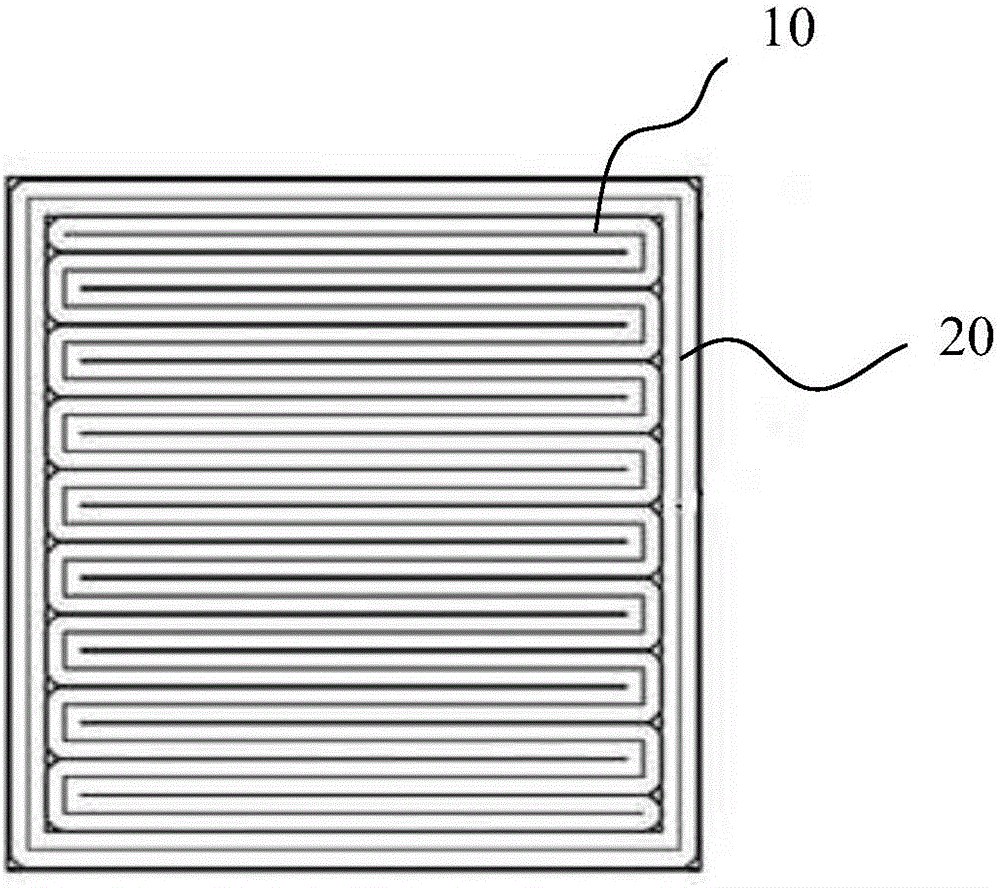

[0009] Combine below figure 1 , figure 2 , to further describe the present invention.

[0010] A laser scanning path of a photocuring 3D printer. The laser scans a liquid photosensitive resin. The laser scanning path includes an inner filling path 10 and an outer edge path 20. The outer edge path 20 surrounds the outer periphery of the inner filling path 10. The laser follows the After the scanning path is scanned, the cured photosensitive resin is spliced into one body. When the light-curing 3D printer scans, use laser to scan the photosensitive resin of each layer, first scan along the inner filling path 10, and the scanned photosensitive resin is cured and spliced together, and then scanned along the outer edge path 20, along the The cured photosensitive resin is the outer layer of the printed product after being scanned by the outer edge-wrapping path 20 , and the scanning of the outer edge-wrapping path 20 has the effect of locking the edge, so that the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com