High-speed and high-efficiency safety guarantee ship

A safe and efficient technology, applied in the direction of ship safety, ship propulsion, ship parts, etc., can solve the problems of slow injection speed, rarely used, low speed and low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

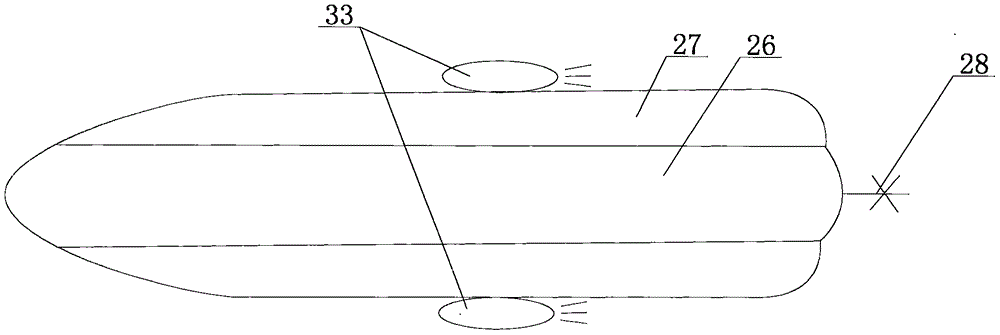

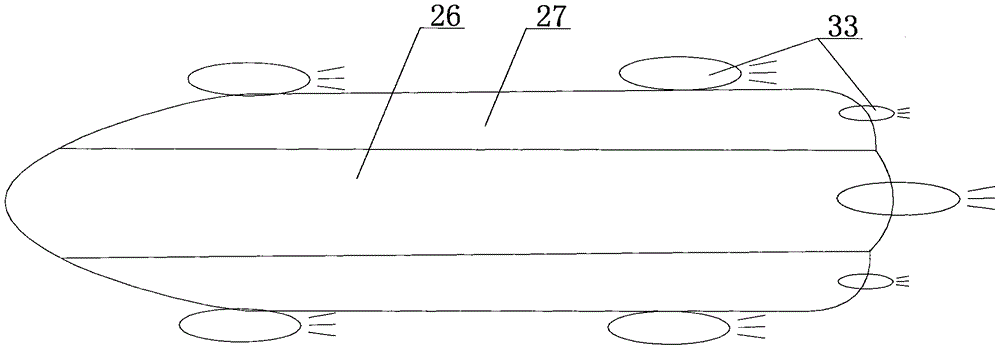

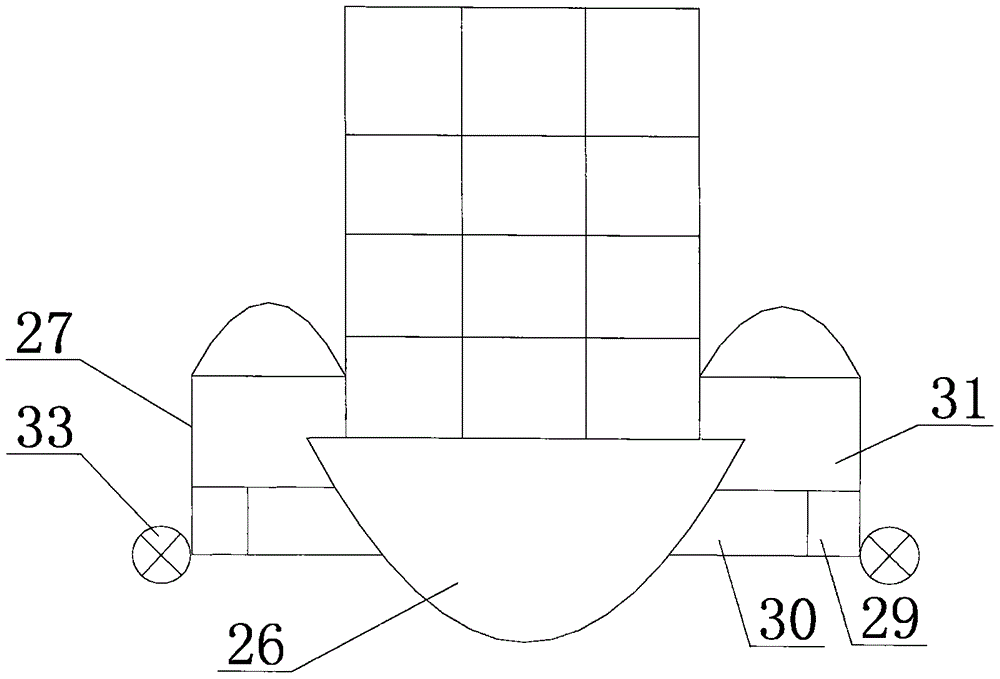

[0040]A high-speed and high-efficiency safety guarantee ship, comprising a ship body 26 and a fully enclosed safety guarantee buoyancy chamber 27, at least one fully enclosed safety guarantee buoyancy chamber 27 is arranged on both sides of the ship body 26, and the front end of the fully enclosed safety guarantee buoyancy chamber 27 is inclined Arc-shaped structure, the distance between the bottom surface of the fully enclosed safety guarantee buoyancy chamber 27 and the bottom surface of the ship body 26 is not less than 1 meter; the outer bottoms of the fully enclosed safety guarantee buoyancy chambers 27 on both sides are respectively provided with at least one axial flow electric pump Jet propeller, the axial-flow electric pump jet propeller includes at least one set of dust removal device, the dust removal device is connected to the rubber nozzle 17 and the direction-adjusting connecting pipe 18 in turn through at least one power propulsion unit, and the dust removal devic...

Embodiment 2

[0042] A high-speed and high-efficiency safety guarantee ship, comprising a ship body 26 and a fully enclosed safety guarantee buoyancy chamber 27, at least one fully enclosed safety guarantee buoyancy chamber 27 is arranged on both sides of the ship body 26, and the front end of the fully enclosed safety guarantee buoyancy chamber 27 is inclined Arc-shaped structure, the distance between the bottom surface of the fully enclosed safety guarantee buoyancy chamber 27 and the bottom surface of the ship body 26 is not less than 1 meter; the outer bottoms of the fully enclosed safety guarantee buoyancy chambers 27 on both sides are respectively provided with at least one axial flow electric pump Jet propeller, the axial-flow electric pump jet propeller includes at least one set of dust removal device, the dust removal device is connected to the rubber nozzle 17 and the direction-adjusting connecting pipe 18 in turn through at least one power propulsion unit, and the dust removal devi...

Embodiment 3

[0045] A high-speed and high-efficiency safety guarantee ship, comprising a ship body 26 and a fully enclosed safety guarantee buoyancy chamber 27, at least one fully enclosed safety guarantee buoyancy chamber 27 is arranged on both sides of the ship body 26, and the front end of the fully enclosed safety guarantee buoyancy chamber 27 is inclined Arc-shaped structure, the distance between the bottom surface of the fully enclosed safety guarantee buoyancy chamber 27 and the bottom surface of the ship body 26 is not less than 1 meter; the outer bottoms of the fully enclosed safety guarantee buoyancy chambers 27 on both sides are respectively provided with at least one axial flow electric pump Jet propeller, the axial-flow electric pump jet propeller includes at least one set of dust removal device, the dust removal device is connected to the rubber nozzle 17 and the direction-adjusting connecting pipe 18 in turn through at least one power propulsion unit, and the dust removal devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com