A highly economical energy heat conversion system and method with near-zero emission of carbon dioxide

A carbon dioxide, near-zero emission technology, applied in the direction of gasification process, chemical industry, climate sustainability, etc., can solve the problem of limiting the commercialization process of carbon dioxide capture and storage technology, the overall system efficiency and economic decline of energy heat conversion, Unfavorable carbon dioxide emission reduction targets and other issues, to achieve the effect of overcoming difficult carbon dioxide treatment, high energy utilization efficiency, and compact system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose and technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] The basic idea and purpose of the present invention are: if the carbon dioxide generated in the energy heat conversion process can be utilized as a resource, the economy of the system can be improved while achieving the goal of near-zero emission of carbon dioxide, which is extremely helpful for promoting the development of carbon dioxide emission reduction technology important practical significance.

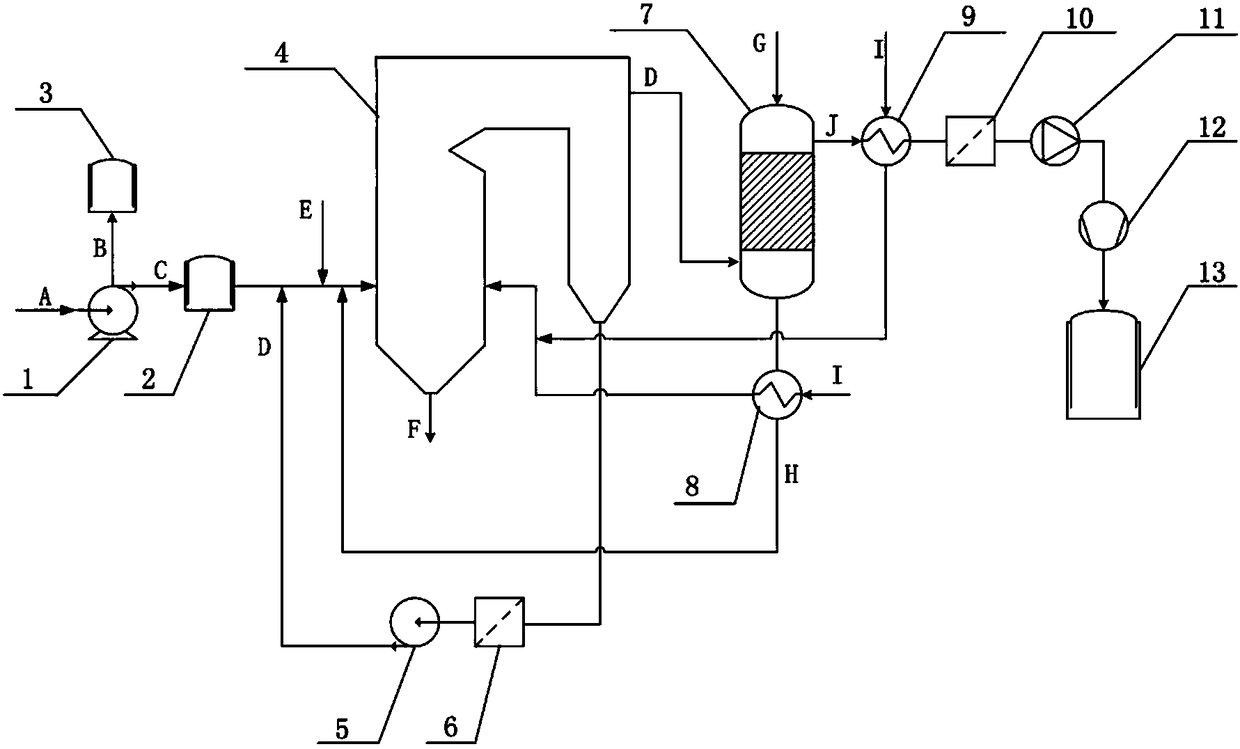

[0031] A highly economical energy-to-heat conversion system with near-zero CO2 emissions for this purpose such as figure 1 shown. Using this system, a highly economical energy-to-heat conversion with near-zero carbon dioxide emissions can be achieved in the following ways:

[0032] Air separation equipment 1 separates nitrogen B and oxygen C in air A, nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com