Near-zero-emission coal gasification power generation system with pollutant control and power generation method

A near-zero emission, power generation system technology, applied in the direction of electrochemical generators, circuits, fuel cells, etc., can solve the problems of unfavorable environmental protection, exhaust gas discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

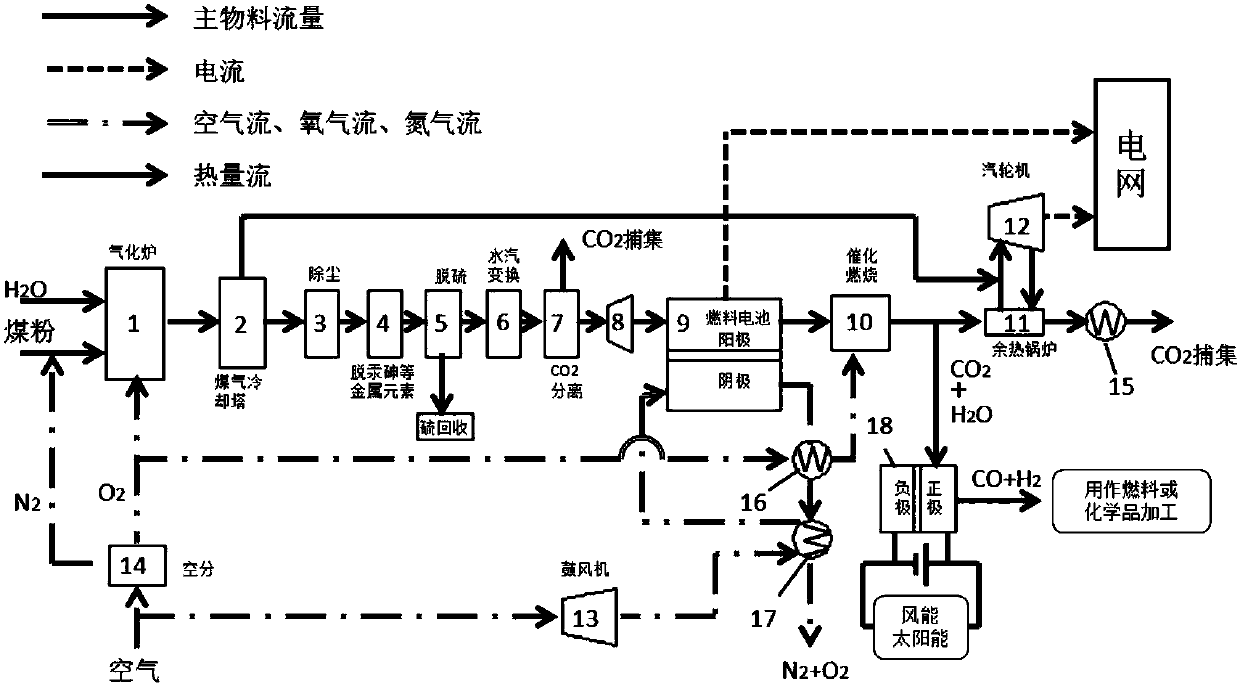

[0014] Embodiment 1: In this embodiment, a near-zero-emission coal gasification power generation system with pollutant control includes a gasifier 1, and the inlet of the gasifier 1 is connected to the reaction raw material pulverized coal, H 2 O and O 2 Outlet, the high-temperature gas outlet of the gasifier 1 is connected to the inlet of the gas cooling tower 2, the high-temperature steam outlet of the gas cooling tower 2 is connected to the inlet of the steam turbine 12, the cooling gas outlet of the gas cooling tower 2 is connected to the inlet of the dust removal device 3, and the clean gas of the dust removal device 3 The outlet is sequentially connected to the volatile alkali metal removal device 4, the desulfurization device 5, the water vapor shift device 6, the CO2 separation device 7, the expander 8 and the anode side of the fuel cell 9, and the cathode side of the fuel cell 9 is connected to the blower 13 through The hot air from the third heat exchanger 17 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com