Continuous pigment dyeing technology with near zero emission effect for fibers

A near-zero emission and paint dyeing technology, applied in the field of paint dyeing, can solve problems such as complexity, odor pollution, and easy-to-fading operation process, and achieve the ideal effect of near-zero emission, reduced pollution, and better dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

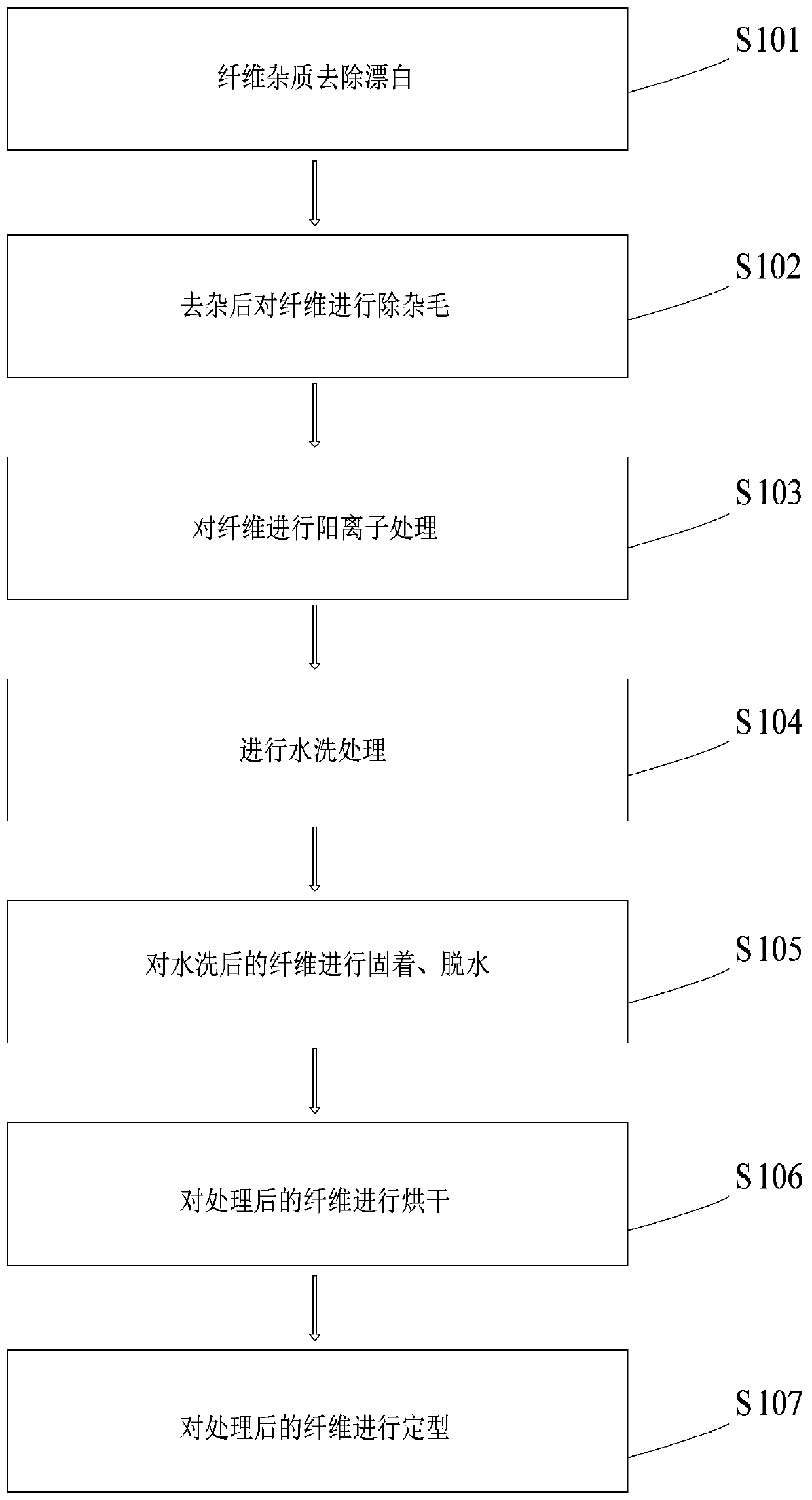

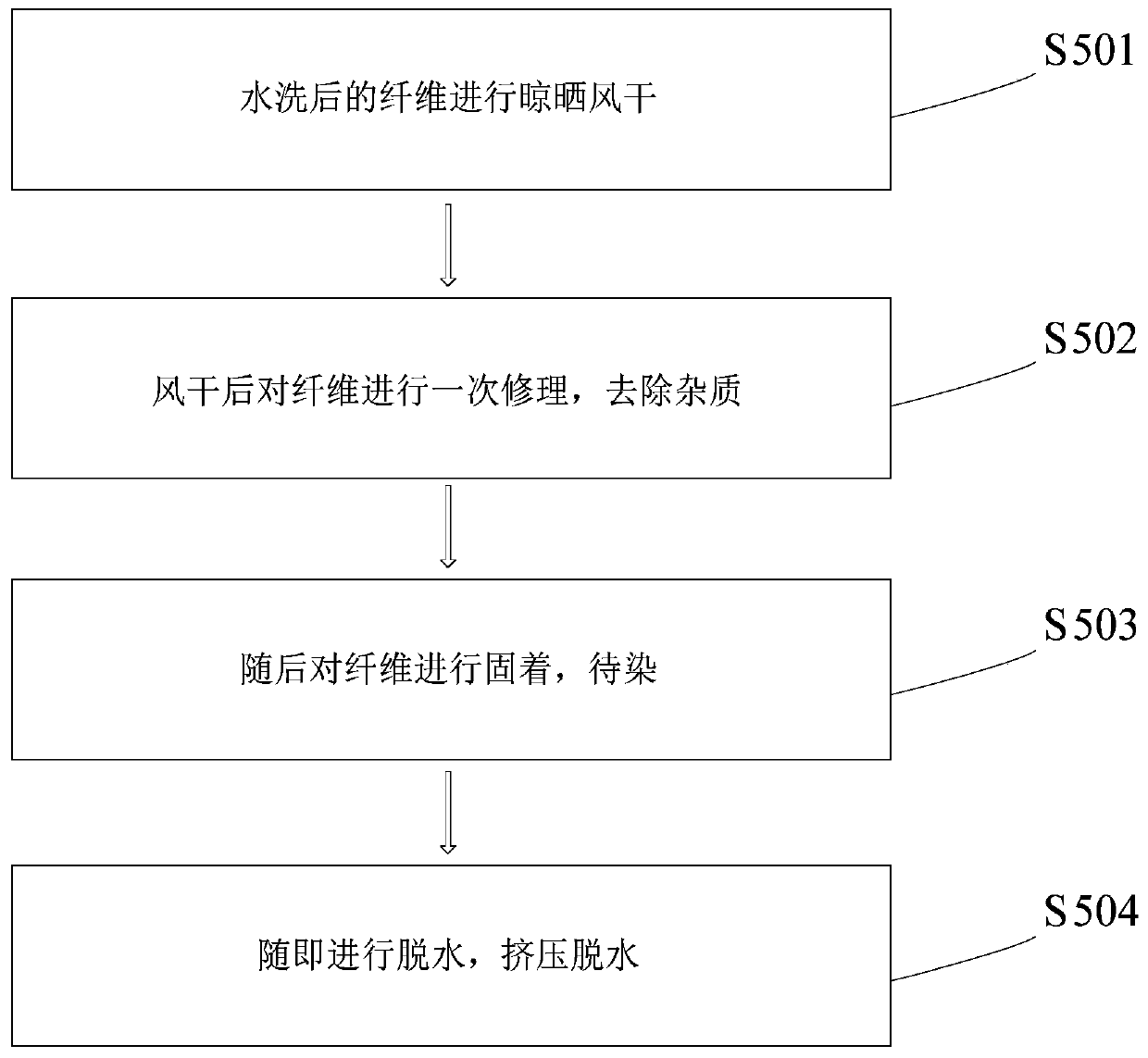

[0067] 1. Remove and bleach fiber impurities, prepare a stainless steel basin, add clean water within a reasonable range, and then add white fibers within a reasonable range to stain clean, stir, put in the fiber cloth and soak for 30-35 minutes, rinse well, and remove impurities during the process. Leak the net to bring out impurities;

[0068] 2. After removing the impurities, the fiber is removed, the specific operation steps are as follows:

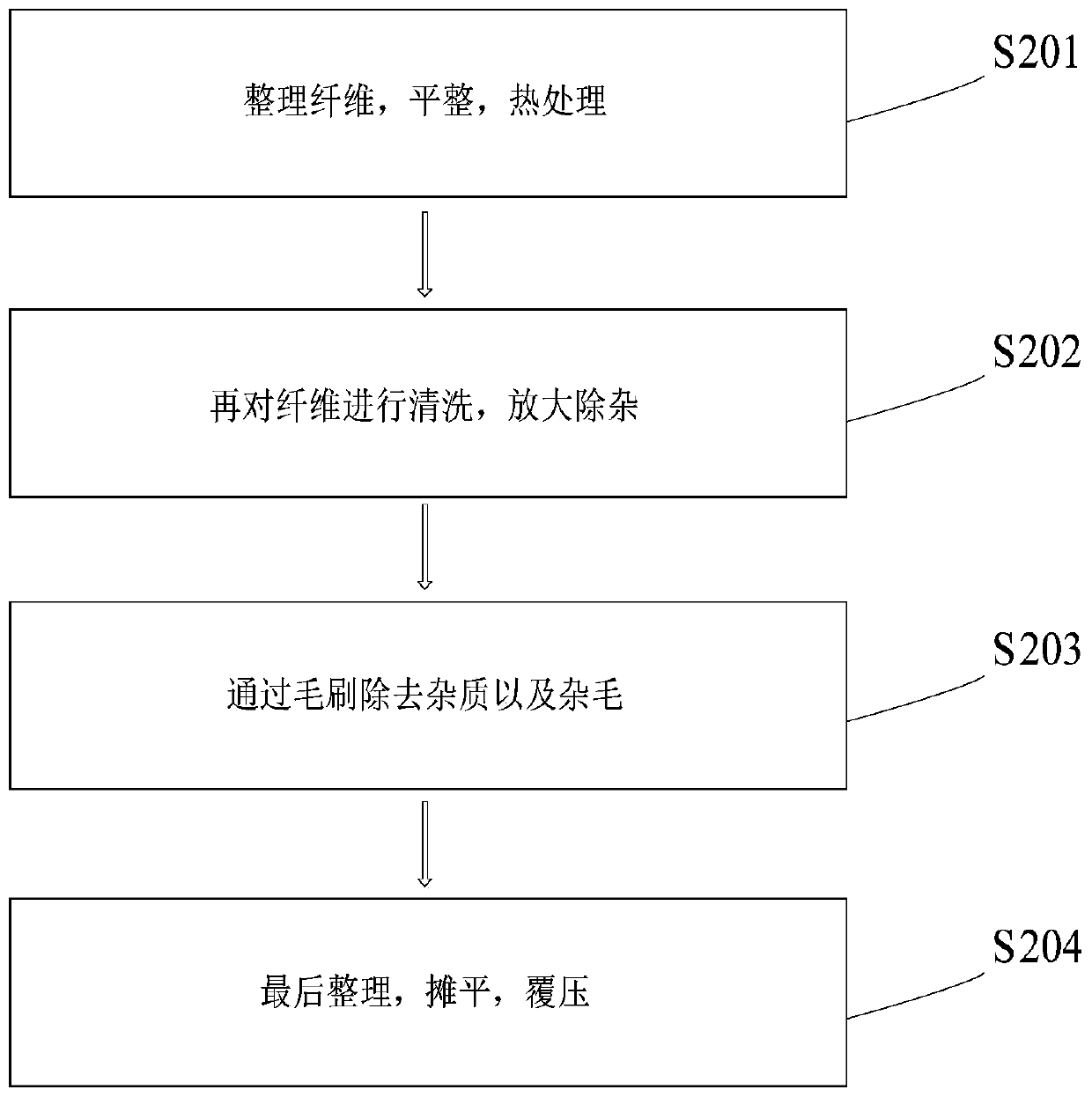

[0069] The first step: Place the fibers on a clean stainless steel plate, arrange the fibers, then level them with a nylon brush, and then use a hot air blower with a temperature of 15°C-20°C for auxiliary drying heat treatment;

[0070] Step 2: Clean the fiber again. When cleaning, use clean water to determine the cleaning time within a reasonable range, then use a magnifying glass to observe and enlarge, and finally remove impurities;

[0071] The third step: remove impurities and miscellaneous hairs with a brush, and then flatten the clean...

specific Embodiment 2

[0083] 1. Remove and bleach fiber impurities, prepare a stainless steel basin, add clean water within a reasonable range, and then add white fibers within a reasonable range to stain clean, stir, put in the fiber cloth and soak for 30-35 minutes, rinse well, and remove impurities during the process. Leak the net to bring out impurities;

[0084] 2. After removing the impurities, the fiber is removed, the specific operation steps are as follows:

[0085] The first step: Put the fiber on a clean stainless steel plate, arrange the fiber, then level it with a nylon brush, and then use a hot air blower with a temperature of 20℃-25℃ for auxiliary drying heat treatment;

[0086] Step 2: Clean the fiber again. When cleaning, use clean water to determine the cleaning time within a reasonable range, then use a magnifying glass to observe and enlarge, and finally remove impurities;

[0087] The third step: remove impurities and miscellaneous hairs with a brush, and then flatten the cleaned misce...

specific Embodiment 3

[0099] 1. Remove and bleach fiber impurities, prepare a stainless steel basin, add clean water within a reasonable range, and then add white fibers within a reasonable range to stain clean, stir, put in the fiber cloth and soak for 30-35 minutes, rinse well, and remove impurities during the process. Leak the net to bring out impurities;

[0100] 2. After removing the impurities, the fiber is removed, the specific operation steps are as follows:

[0101] The first step: Put the fiber on a clean stainless steel plate, arrange the fiber, then use a nylon brush to level it, and then use a hot air blower with a temperature of 25℃-35℃ for auxiliary drying heat treatment;

[0102] Step 2: Clean the fiber again. When cleaning, use clean water to determine the cleaning time within a reasonable range, then use a magnifying glass to observe and enlarge, and finally remove impurities;

[0103] The third step: remove impurities and miscellaneous hairs with a brush, and then flatten the cleaned mis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com