Treatment method for removing and recycling heavy metals in wastewater sludge based on biological sulfur circulation

A technology of wastewater sludge and treatment method, which is applied in biological sludge treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost, complicated operation, secondary pollution, etc. The effect of low consumption cost, less consumption and saving processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

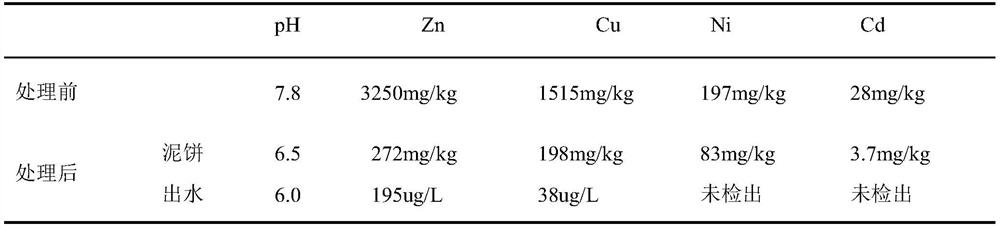

[0045] In this example, the biosulfur cycle is used to remove and recover heavy metals from wastewater sludge containing various heavy metal elements.

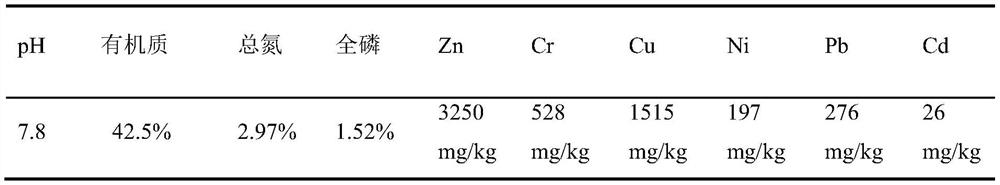

[0046] The sample was collected from the sludge thickening tank of a sewage treatment plant in an industrial park in Jiangsu. The solid content of the sludge was 3.2%. The basic properties are shown in Table 1. Compared with the sludge agricultural pollutant control standard (GB4284-84), the content of heavy metals such as Zn, Cu, Cd and Ni in the sludge exceeds the standard by 2-6.5 times.

[0047] Table 1 Basic properties of sludge

[0048]

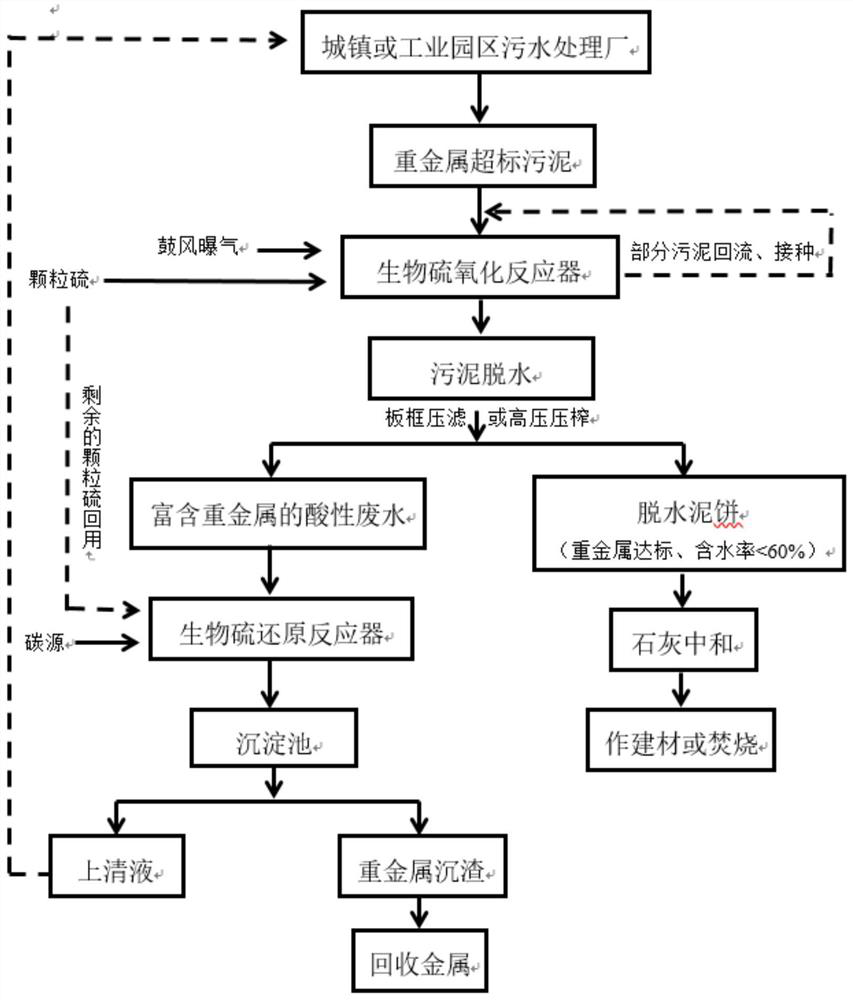

[0049] The present embodiment is aimed at the treatment of above-mentioned sludge, and flow chart is as follows figure 1 shown, including the following steps:

[0050] Biological sulfur elemental oxidation stage (sulfur pellets): Add sludge with a solid content of 3.2% and 8.0g / L sulfur pellets to the biological sulfur oxidation reactor, blow and aerate for 10 days at 25°C, and the...

Embodiment 2

[0070] This embodiment is the removal and recovery of only a single high-concentration heavy metal Cu in the wastewater sludge of copper electroplating by biological sulfur circulation.

[0071]The sample is electroplating sludge from a wastewater treatment plant in an electroplating industrial park in Shandong. The solid content of the sludge is about 30%, and the pH is 6.8. The sludge mainly contains copper, and the total copper content is 10280mg / kg.

[0072] The treatment method for the removal and recovery of heavy metals in the sludge based on the biosulfur cycle of this embodiment includes the following steps:

[0073] Biological sulfur elemental oxidation stage (sulfur flakes): Add electroplating sludge with a solid content of 3% diluted with tap water and 12.0g / L sulfur flakes into the biological sulfur oxidation reactor, stir evenly and aerate for 5 days at 20°C , the pH of the sludge was reduced to 3, and the remaining sulfur flakes in the reactor were taken out, wa...

Embodiment 3

[0077] This embodiment is the removal and recovery of only a single high-concentration heavy metal Cu in the wastewater sludge of copper electroplating by biological sulfur circulation.

[0078] The sample is the same copper electroplating sludge as in Example 2. The treatment method for the removal and recovery of heavy metals in the sludge based on the biosulfur cycle of this embodiment includes the following steps:

[0079] Biological sulfur elemental oxidation stage (sulfur pellets + sulfur flakes): Add electroplating sludge with a solid content of 10% diluted with tap water, 5g / L sulfur pellets and 5g / L sulfur flakes to the biosulfur oxidation reactor at 35°C Down, stirred evenly and aerated for 15 days, the pH of the sludge dropped to 2.2, and the remaining sulfur balls and sulfur flakes in the reactor were taken out, washed with tap water and set aside.

[0080] Dehydration stage: 50% (v / v) of the sludge in the reactor is retained, and the rest of the sludge is dehydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com