X-shaped anti-floating uplift pile

An uplift-resistant pile and pile body technology, applied in sheet pile walls, protection devices, buildings, etc., can solve the problems of the pile bottom sediment cleaning, the difficulty of monitoring the judgment of the bearing layer, the integrity of the pile body, and the large deformation after construction. Achieve the effect of expanding the anti-floating area, reducing the length and cross-sectional area, and reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

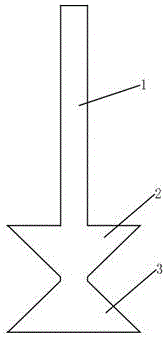

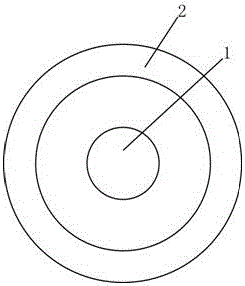

[0030] Such as Figure 1-3 As shown, an X-type anti-floating and anti-lift pile includes a pile body 1, the pile body 1 is cylindrical, and the pile body 1 extends to the outside of the pile body 1 to form a first circular cone with the pile body 1 as the rotation axis and no bottom surface body 2, the second cone body 3, the first cone body 2 is located above the second cone body 3 and the apex angles of the two are connected, the first cone body 2, the second cone body 3 along the pile body 1 The plane where the central axis is located is an X-shaped cross-sectional plane.

[0031] The first cone body 2 and the second cone body 3 have the same size.

[0032] The first conical body 2 and the second conical body 3 are located at the bottom of the pile body 1 .

[0033] Such as Figure 4-7 As shown, the specific construction process is as follows: (1) The construction sequence is to make a cylindrical hole 4 according to the rotary grouting pile process; (2) When the pile fo...

Embodiment 2

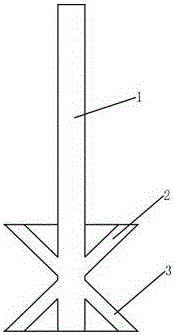

[0035] Such as image 3 , 8 As shown in and 9, an X-type anti-floating and uplift pile includes a pile body 1, the pile body 1 is cylindrical, and the pile body 1 extends to the outside of the pile body 1 to form a first shaft with the pile body 1 as the rotation axis and no bottom surface. Cone 2, the second cone 3, the first cone 2 is located above the second cone 3 and the apex angles of the two meet, the first cone 2, the second cone 3 along the The plane where the central axis of the pile body 1 is located is an X-shape after being sectioned.

[0036] The first cone body 2 and the second cone body 3 have the same size.

[0037] The first conical body 2 and the second conical body 3 are located in the middle of the pile body 1 .

[0038] Such as Figure 10-13 As shown, the specific construction process is as follows: (1) The construction sequence follows the cylindrical hole 4 of the rotary grouting pile process; (2) In the middle of the pile foundation, the drilling r...

Embodiment 3

[0040] Such as image 3 , 14 15, an X-type anti-floating and uplift pile includes a pile body 1. The pile body 1 is cylindrical. Cone 2, the second cone 3, the first cone 2 is located above the second cone 3 and the apex angles of the two meet, the first cone 2, the second cone 3 along the The plane where the central axis of the pile body 1 is located is an X-shape after being sectioned.

[0041] The first cone body 2 and the second cone body 3 have the same size.

[0042] The first conical body 2 and the second conical body 3 are located on the top of the pile body 1 .

[0043] Such as Figure 16-19 As shown, the specific construction process is as follows: (1) The construction sequence is to make a cylindrical hole 4 according to the rotary grouting pile process; (2) When the pile foundation is close to the top, the drilling rig extends out the oblique rotary drill to make a tapered hole 5; (3 ) The drilling rig is lifted up for a certain distance, and the reverse rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com