Construction method for preventing slurry from overflowing in underground diaphragm wall pouring construction

A construction method, the technology of ground connection wall, which is applied in the direction of construction, sheet pile wall, foundation structure engineering, etc., can solve the problems of wall mud overflow, increase the total amount of mud, and enter the guide wall, so as to avoid mud overflow and reduce the overall The effect of reducing the amount and reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

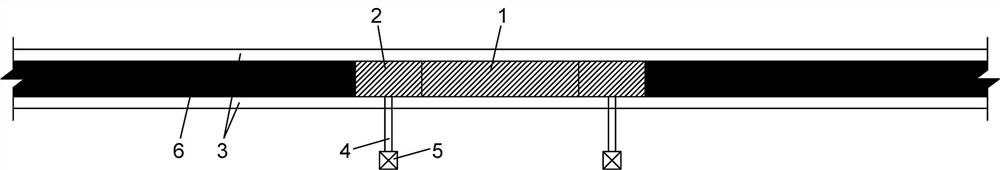

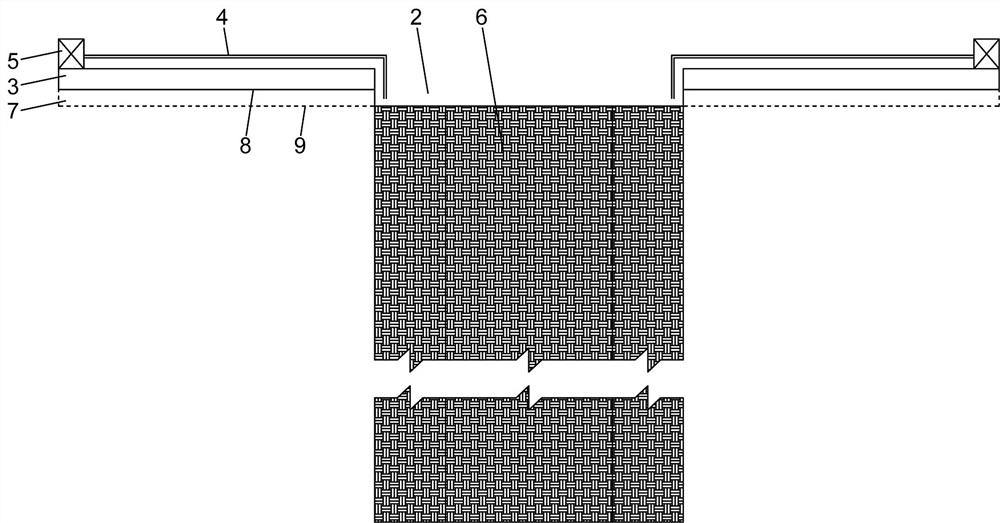

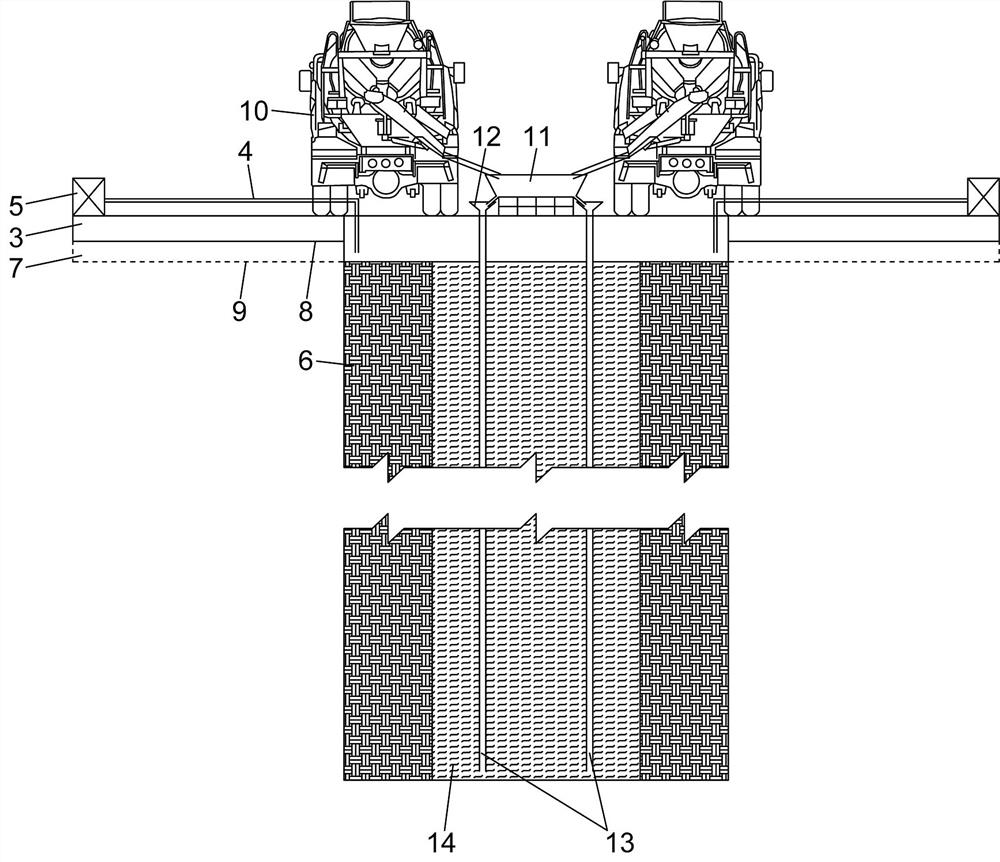

[0033] like Figure 1-6 Among them, a mud spill-proof construction method used in the construction of ground connecting wall is characterized by comprising the following steps:

[0034] 1) Before excavation of the first-phase groove 1 of the ground-connecting wall, excavate the area between the first-phase groove 1 of the ground-connecting wall and the guide wall 3 at the top of the adjacent unexcavated area 6, and the excavation scope is the design bottom elevation of the guide wall 8 to the design bottom elevation of the crown beam 9, the mud buffer zone 2 will be formed after the excavation is completed;

[0035] 2) Lay a slurry discharge pipe 4 in the mud buffer zone 2, and the slurry discharge pipe 4 is connected to the mud pump 5;

[0036] 3) Carry out the excavation of the first-phase groove 1 of the ground connecting wall;

[0037] 4) Carry out the first sealing operation of groove 1 of the first phase of the ground connection wall;

[0038] 4.1) A pouring frame is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com