Composite drilling bit with PDC combined tooth

A composite drill bit and bit body technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of easy wear of cutting teeth and affect the service life of drill bits, and achieve the effect of improving wear resistance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

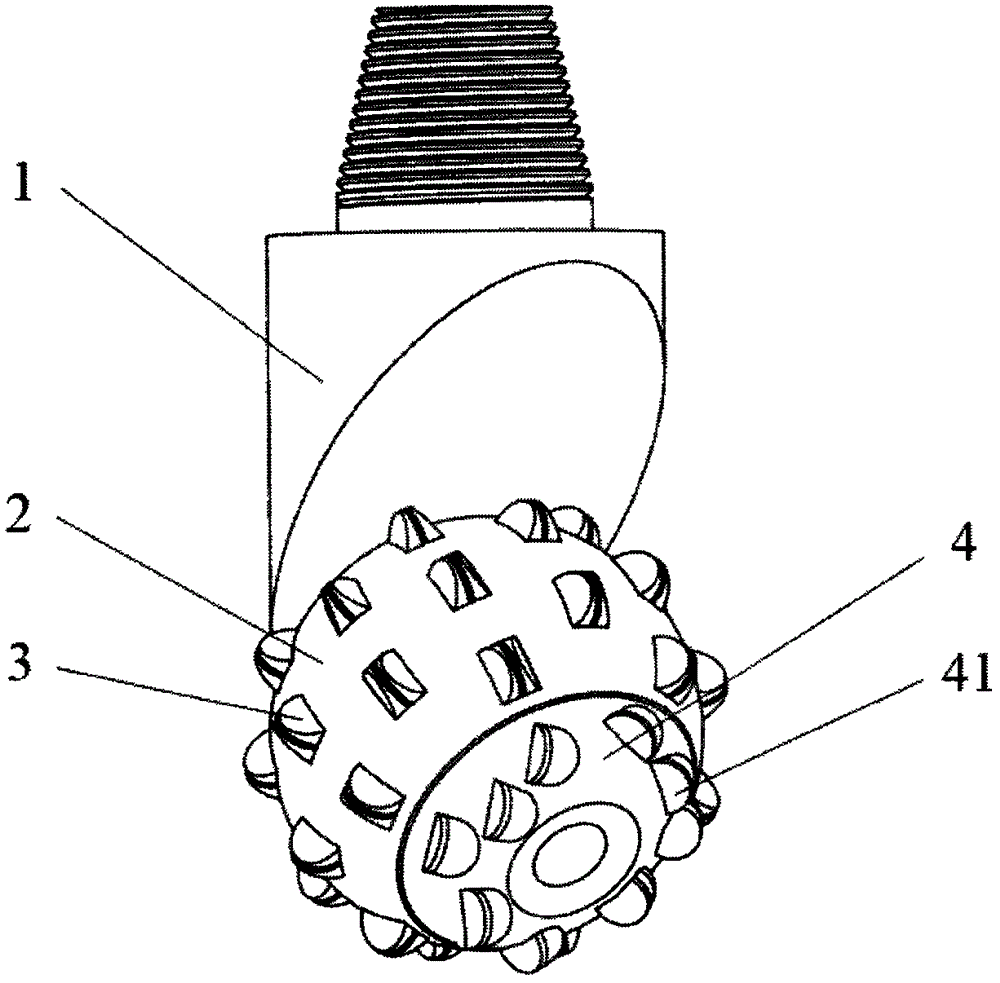

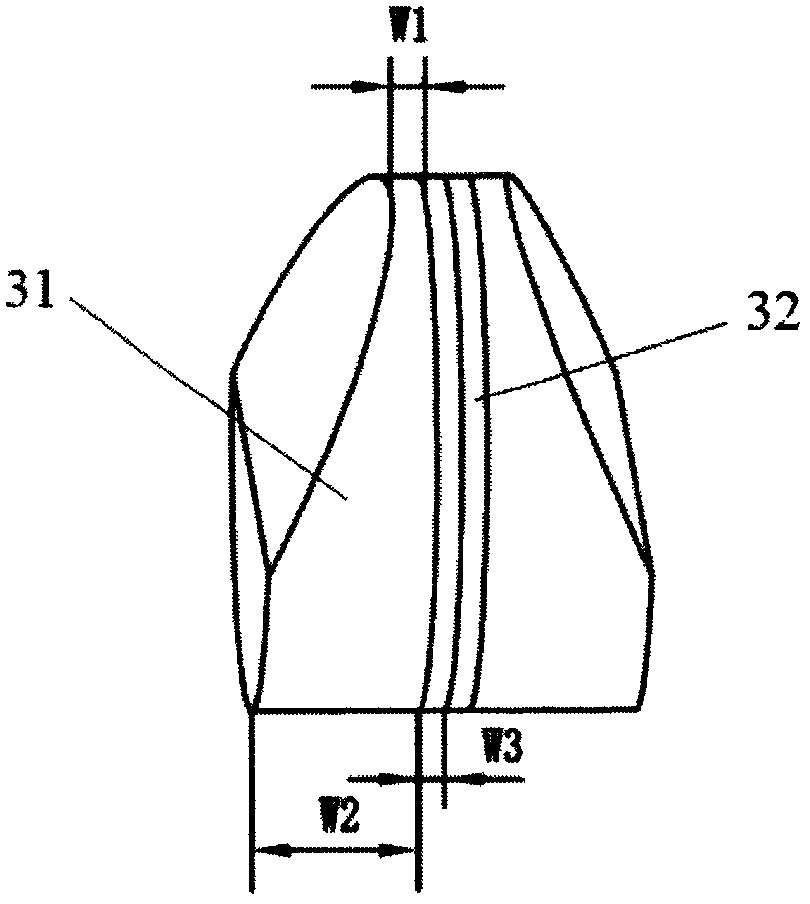

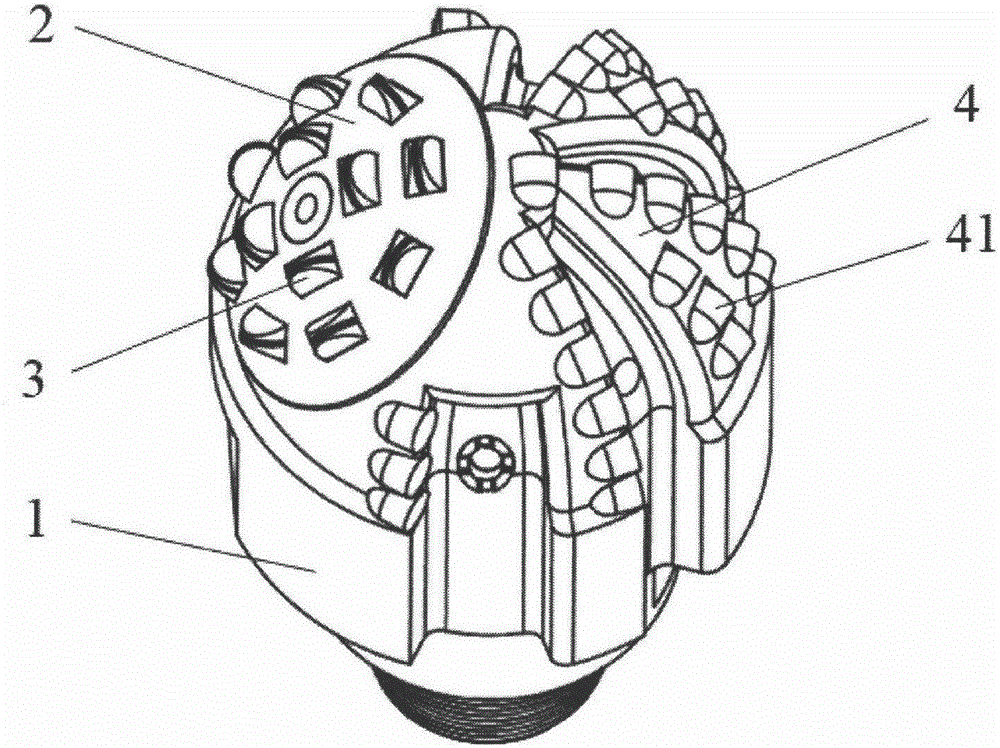

[0036] like Figure 1-4 As shown, a composite drill bit with PDC combined teeth includes a drill body 1, a fixed cutting structure 4 and a cone 2, the fixed cutting structure 4 is provided with a fixed cutting tooth 41, and the cone 2 and the drill body 1 are rotationally connected. The cone 2 can rotate relative to the bit body 1. The cone 2 is provided with cutting teeth. The drill body 1 is provided with at least one cone 2. At least one of the cutting teeth on the cone 2 is a PDC combination tooth 3. The PDC combination tooth 3. It is composed of two PDC teeth. The PDC teeth are composed of a body 31 and a polycrystalline diamond layer 32 covering the entire supporting surface of the body or a body 31 and a polycrystalline diamond layer 32 covering more than 60% of the supporting surface of the body. The two The combination of PDC teeth is that the polycrystalline diamond layer 32 is closely attached, and is clamped by the two outer bodies 31 to form a four-layer sandwich ...

Embodiment 2

[0038] like Figure 5 , 6 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the outer sides of the body 31 on both sides of the PDC composite tooth 3 are cut off by concave curves to form a PDC composite tooth with a narrow top and a wide bottom. As an option, the body 31 on both sides of the PDC combined tooth 3 is cut off by a concave curve formed by a combination of multiple curves to form a PDC combined tooth with a narrow top and a wide bottom, such as Image 6 shown. Alternatively, the body 31 on both sides of the PDC composite tooth is cut by a concave curve formed by a combination of a curve and a straight line, forming a PDC composite tooth with a narrow upper part and a wider lower part.

Embodiment 3

[0040] This embodiment is basically the same as Embodiment 1, and the difference is that: the angle between the polycrystalline diamond layer plane of the PDC composite tooth 3 and the axial plane passing the setting point of the PDC composite tooth is 45-90°; further, the PDC The included angle between the polycrystalline diamond layer plane of the combination tooth 3 and the axis plane passing through the PDC combination tooth setting point is 60-90°; further, the polycrystalline diamond layer plane of the PDC combination tooth 3 and the PDC combination The included angle between the axial planes of the tooth setting points is 75-90°; in particular, the polycrystalline diamond layer plane of the PDC combined tooth 3 is perpendicular to the axial plane passing through the PDC combined tooth setting points.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com