Composite grouting stop mechanism and shield tunnel boring machine with same

A shield tunnel and composite technology, which is applied in the field of shield machines, can solve the problems of affecting slurry filling, damage to the slurry stop plate, and small support force, so as to improve work efficiency, enhance airtightness, and increase wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

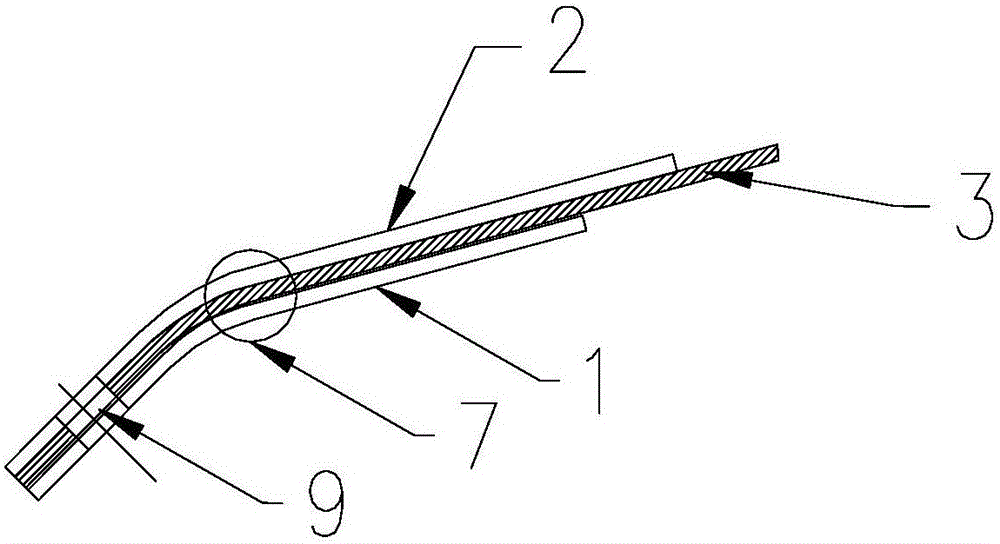

[0021] like figure 1 As shown, a composite type stopper mechanism includes a composite stopper 7, and the composite stopper 7 includes an upper stopper 2 and a lower stopper 1 arranged parallel to each other, and the upper stopper 1 A wear-resistant rubber layer 3 is arranged between 2 and the lower grout plate 1. In the present invention, the setting of the composite anti-slip plate 7 increases the wear resistance; when the upper anti-slurry plate 2 is worn, the wear-resistant rubber layer 3 compensates the worn portion of the upper anti-screw plate 2 under the action of elasticity.

Embodiment 2

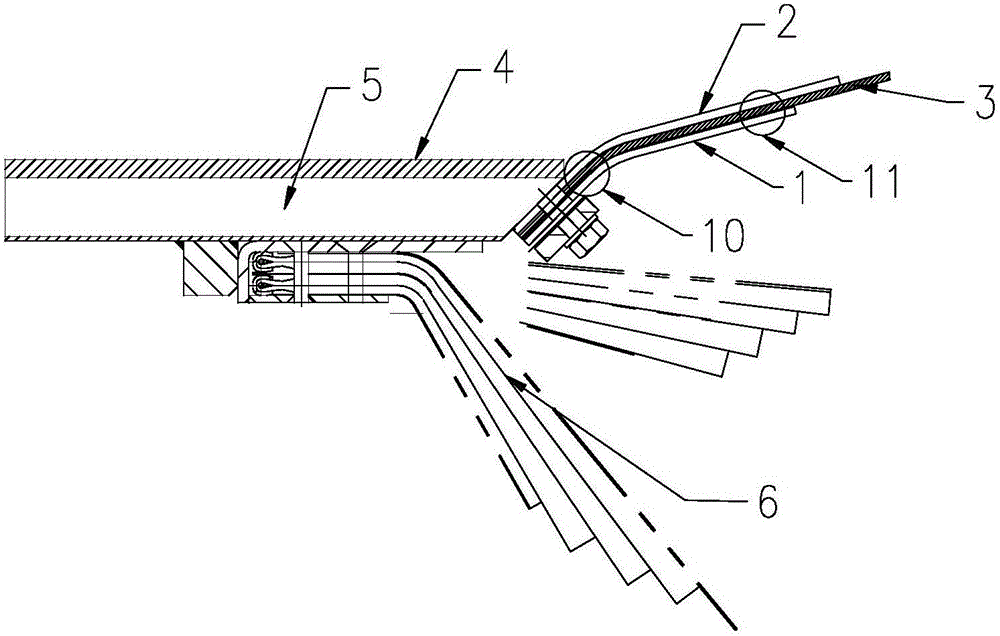

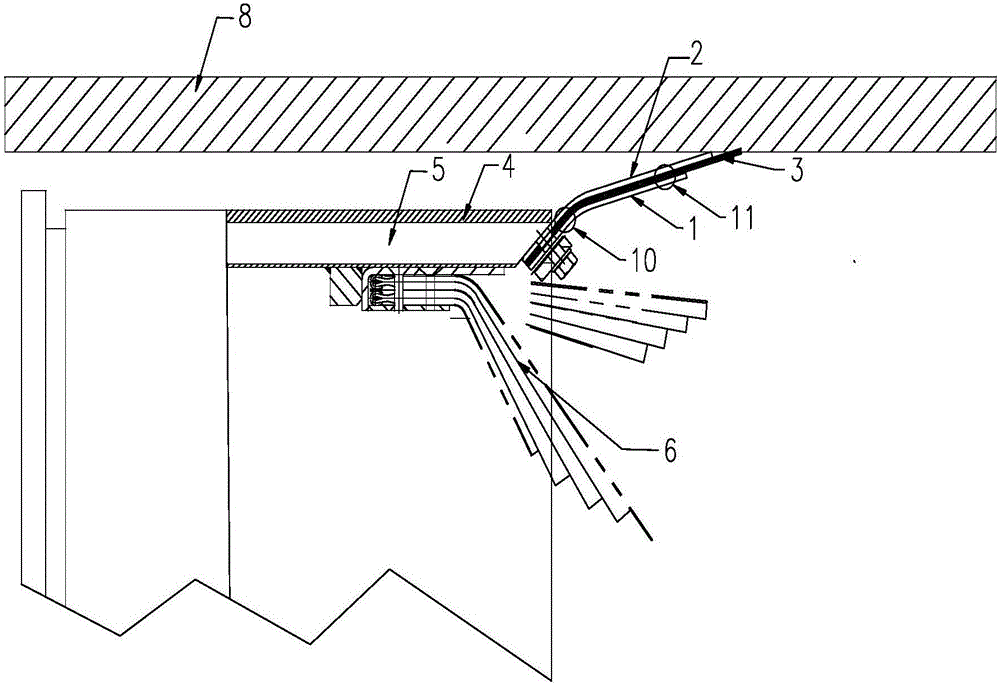

[0023] like image 3 As shown, the present invention also proposes a shield tunnel boring machine, including the composite slurry stop mechanism described in any one of claims 1-5. In the present invention, the setting of the composite anti-slip plate 7 increases the wear resistance; when the upper anti-slurry plate 2 is worn, the wear-resistant rubber layer 3 compensates the worn portion of the upper anti-screw plate 2 under the action of elasticity. Therefore, when the shield machine advances forward, the gap between the rock wall 8 and the shield tail 4 is synchronously grouted, and the composite grout stop plate 7 extends backward due to the force to form a closed space to enhance the airtightness of the grouting environment; prevent the grout from Inverting the front section of the shield will affect the construction, reduce the waste of grout, ensure the installation quality of the segments, and improve work efficiency.

[0024] When the shield machine is excavating, th...

Embodiment 3

[0026] see figure 1 , figure 2 , image 3 In combination with Embodiment 1 and Embodiment 2, one end of the composite type stopper plate 7 is flush, and the flush end of the composite type stopper plate 7 is connected to the spray pipe 5 on the shield tail 4. When assembling, Put the bolts through the fixed holes 9 vertically opened on the composite type stop plate 7, and connect the flush end of the composite type stop plate 7 with the spray pipe 5 on the shield tail 4 through the bolts penetrating through the fix holes 9, wherein the spray The end surface of the pipe 5 is inclined and set at the same inclination angle as the first bending section 10 of the compound type stopper 7, so that the spray pipe 5 and the compound stopper 7 are fixedly installed without gap. The other end is set in a dislocation, and the dislocation end of the composite anti-slurry plate 7 is used to connect with the rock wall 8; wherein, the end of the wear-resistant rubber layer 3 at the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com