Inertia-type hybrid vibration isolator based on piezoelectric stack

A hybrid vibration isolator, piezoelectric stack technology, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of damage, vulnerability to impact, deterioration of active control effect, etc. The effect of small footprint and no deterioration of control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

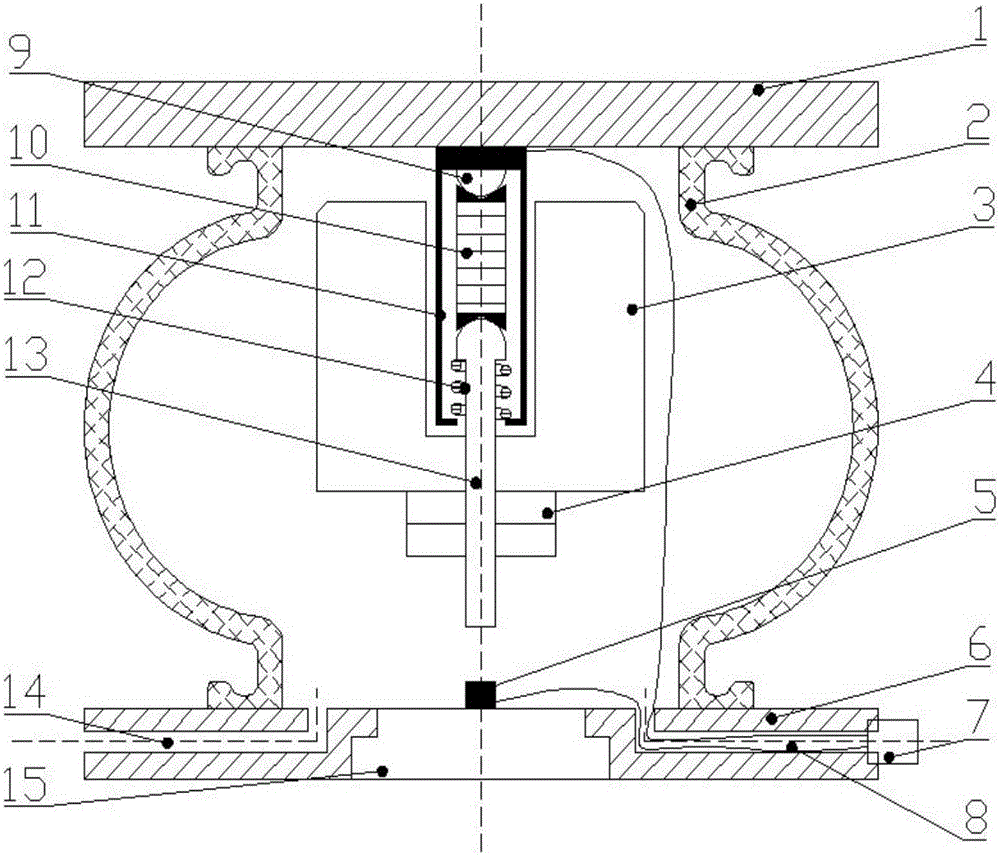

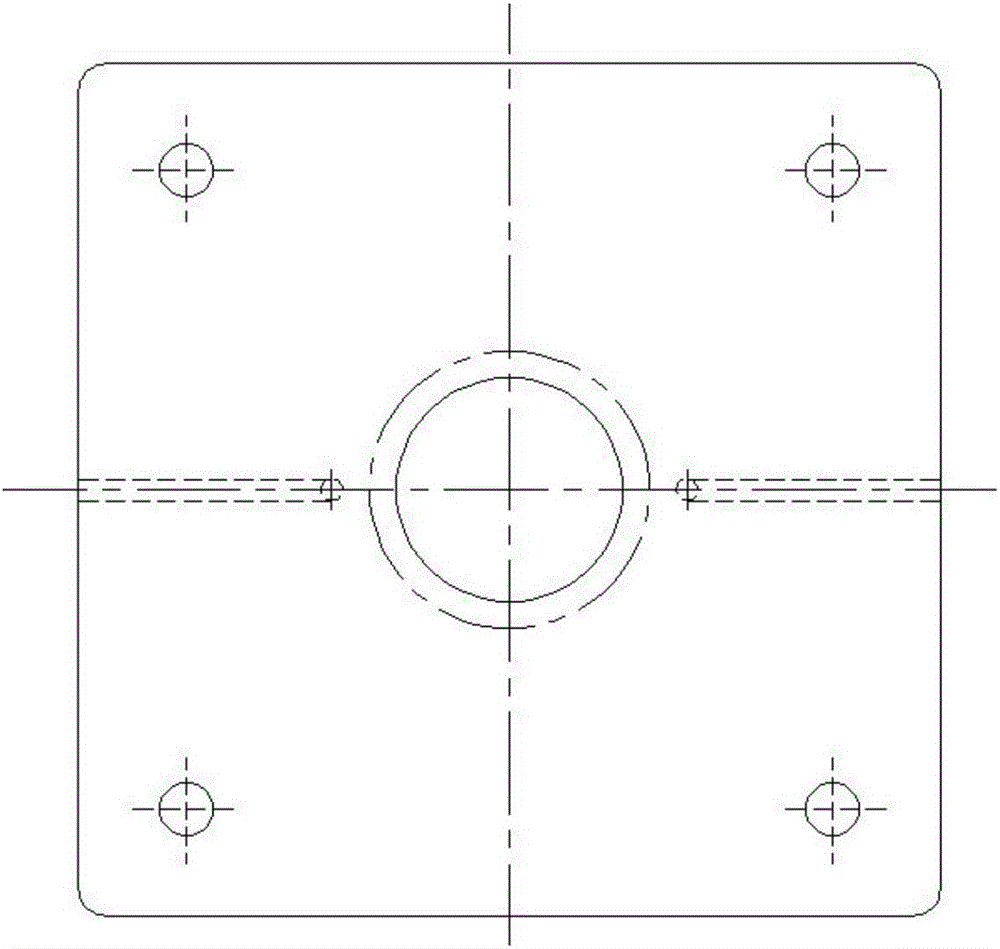

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

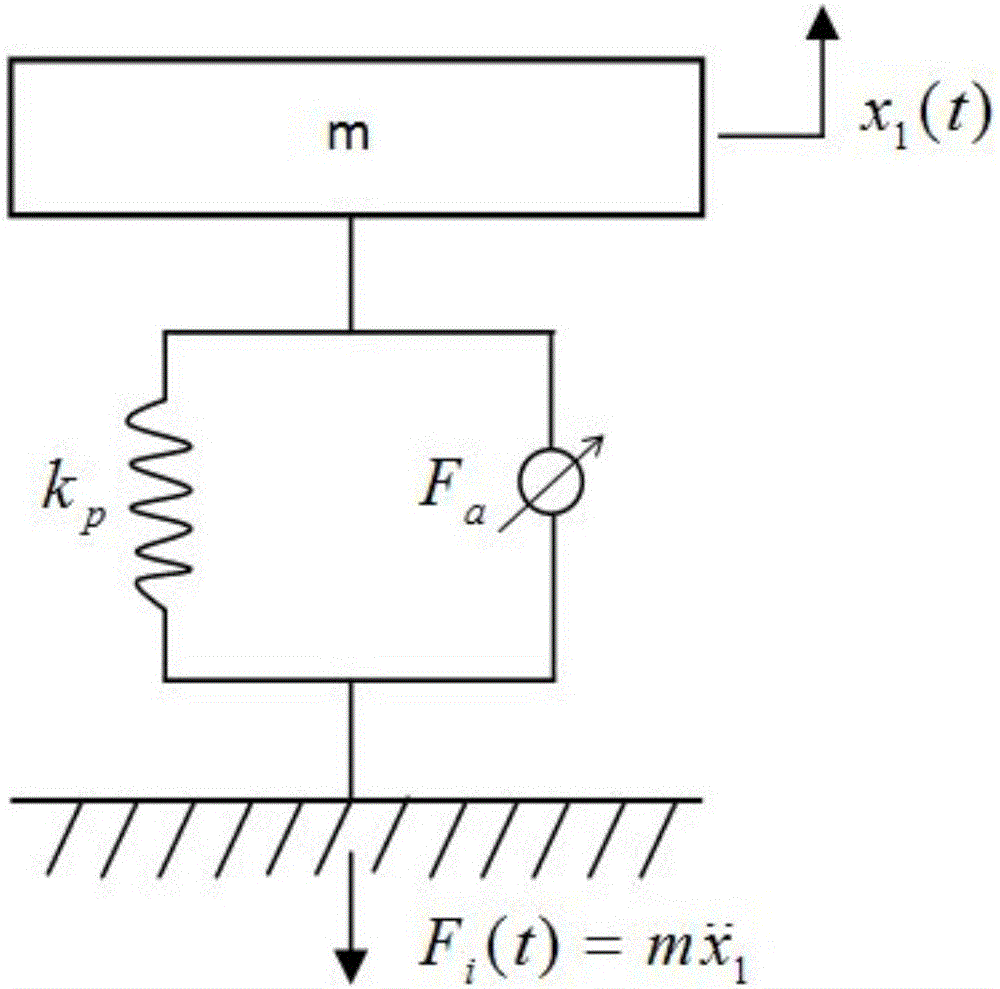

[0023] combine Figure 1-5 , the present invention is an inertial hybrid vibration isolator based on a piezoelectric stack, which is composed of an active actuator, a passive vibration isolation device and a sensor; Rod, inertial mass, additional mass and preloaded spring; the passive vibration isolation device includes a capsule-type elastic capsule, an upper cover and a lower cover.

[0024] The active actuator is composed of a shell, a ball head-taper hole force transmission device, a piezoelectric stack, a force output rod, an inertial mass block, an additional mass block and a preloaded spring. Among them, the piezoelectric stack is formed by stacking N pieces (the number is selected according to specific needs) piezoelectric pieces through the adhesive layer, that is, the method of mechanically connecting in series and electrically connecting in parallel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com