Axial-flow type electromagnetic pilot differential pressure drive large-flow control valve

A technology of pilot pressure and control valve, applied in the direction of balance valve, valve device, valve details, etc., can solve the problem that can not meet the performance index requirements of fast response high-performance attitude control engine, can not use electric valve structure scheme, solenoid valve open, Close the slow response and other problems to achieve the effect of being conducive to closing the fast response, enabling the fast response, opening the response and closing the response optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

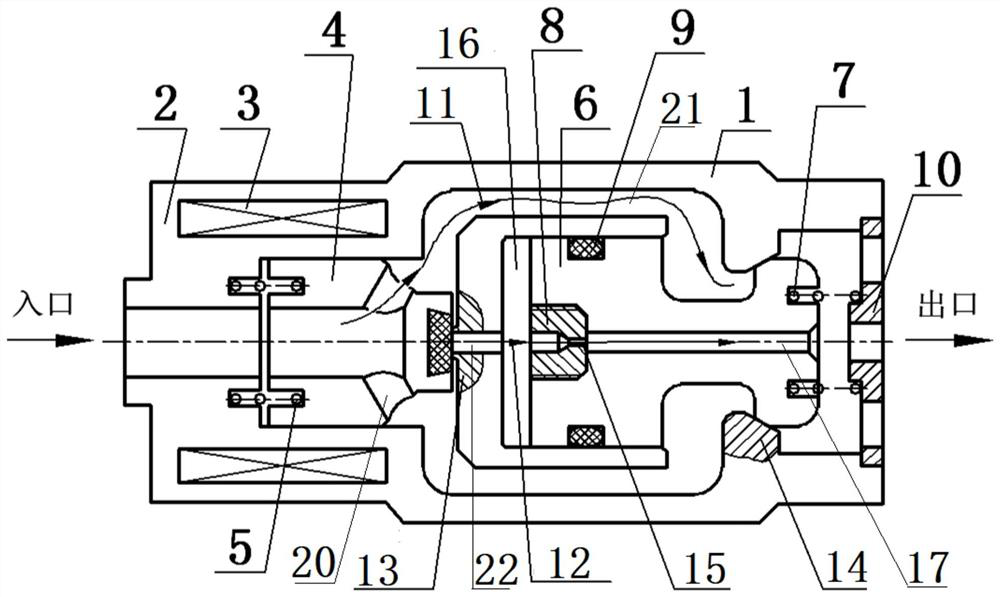

[0024] Such as figure 1 As shown, the axial-flow electromagnetic pilot pressure difference-driven large flow control valve provided by the present invention adopts an axial-flow two-stage pilot structure as a whole, including a small-diameter electromagnetic auxiliary valve coaxially arranged along the axial direction and integrated into one body. The inlet of the solenoid auxiliary valve is the inlet of the control valve, and the outlet of the differential pressure main valve is the outlet of the control valve.

[0025] The electromagnetic auxiliary valve includes an auxiliary valve body 2 , an electromagnetic coil 3 , an auxiliary valve core 4 , an auxiliary reset spring 5 and an auxiliary valve seat 13 .

[0026] The differential pressure main valve includes a main valve body 1 , a main valve core 6 , a reset main spring 7 , a main valve seat 14 and a retainer 10 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com