High-purity ammonia filling system and filling method for high-purity ammonia

A high-purity ammonia and cooling device technology, which is applied in the container filling method, the container discharging method, and the equipment loaded into the pressure vessel, etc., can solve the problems of polluting high-purity ammonia products, avoid pollution, and reduce filling energy consumption. , The effect of convenient filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

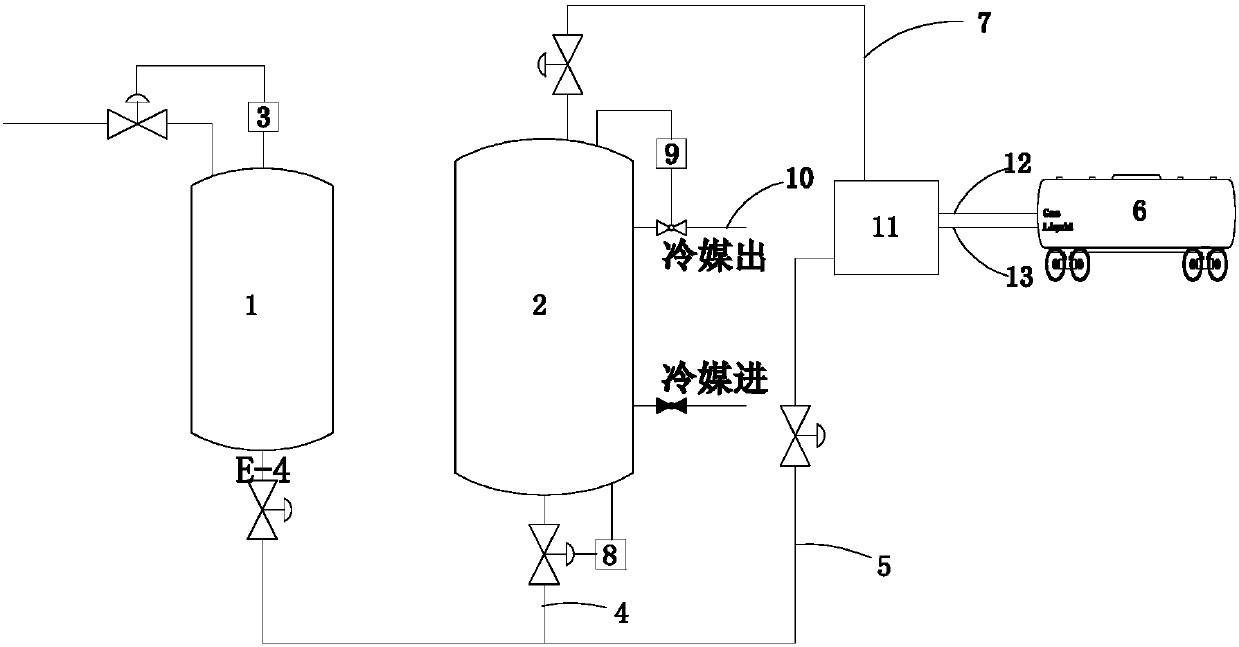

[0018] A high-purity ammonia filling system, such as figure 1 As shown, it includes a product buffer tank 1, a product tank 2 and a cooling device 10. The product buffer tank 1 is connected to the output end of the high-purity ammonia production line, and a first liquid level gauge for detecting the liquid level of the product buffer tank 1 is installed on it. 3. The liquid phase interface of the product buffer tank 1 is connected to the liquid phase interface of the product tank 2 through the first liquid phase pipeline 4, and the liquid phase interface of the tank truck 6 is connected through the second liquid phase pipeline 5 through the filling station 11. Interface connection, the gas phase interface of the product tank 2 is connected to the gas phase interface of the tank car 6 through the product tank gas phase pipeline 7 through the filling station 11, in the first liquid phase pipeline 4, the second liquid phase pipeline 5 and the gas phase pipeline 7 of the product t...

Embodiment 2

[0021] A filling method for filling high-purity ammonia using the filling system in Example 1, comprising the following steps: S1: After the tank car 6 is cleaned, the gas and liquid phase interfaces of the tank car pass through the gas phase pipeline 12 of the tank car, the tank car The liquid phase pipeline 13 of the tanker is connected to the filling station 11, and the gas phase pipeline 12 and the liquid phase pipeline 13 of the tanker are purged, maintained and vacuumed through the filling station 11; S2: the product tank 2 The internal pressure is P1 (by the cooling device 10 to reduce the temperature and pressure), keep the second liquid phase pipeline 5 cut off, open the tank car and the corresponding valve of the pipeline to make the gas phase pipeline 7 of the product tank and the gas phase pipeline 12 of the tank car conduct Thereby reducing the pressure in the tank car 6, along with the continuous operation of the cooling device 10, the pressure in the tank car 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com