Automatic measuring device and method for precision of rolling linear guides

A linear guide, automatic measurement technology, used in measurement devices, mechanical measurement devices, mechanical devices, etc., can solve the problems of inability to guarantee measurement accuracy, high quality requirements of testers, and poor measurement reproducibility, and achieve continuous and reliable test data. Economical and practical, low vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

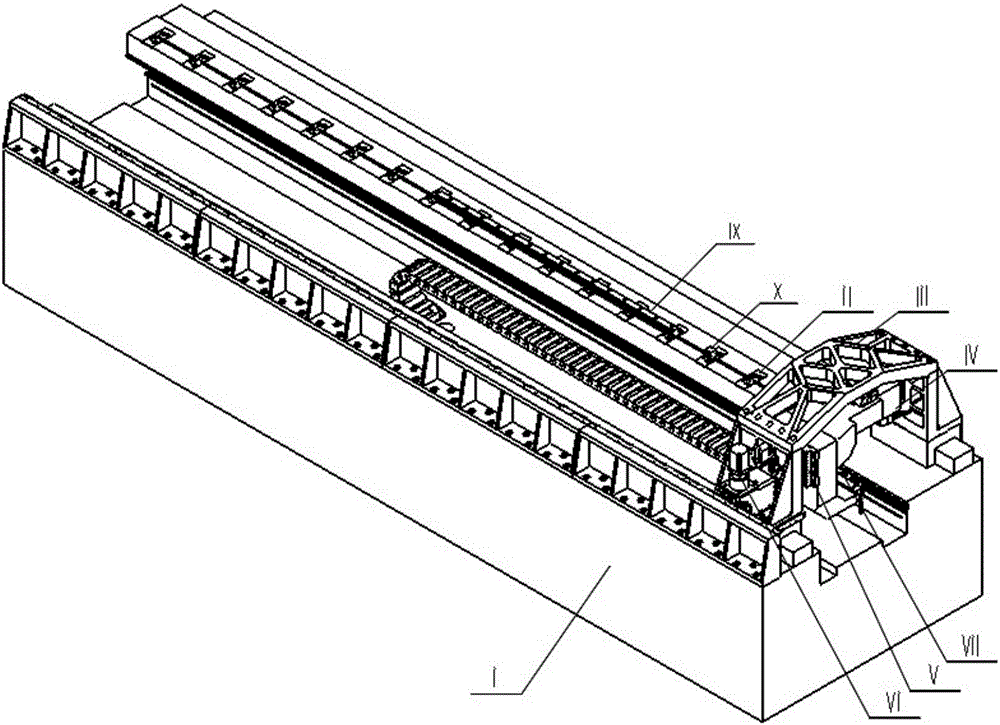

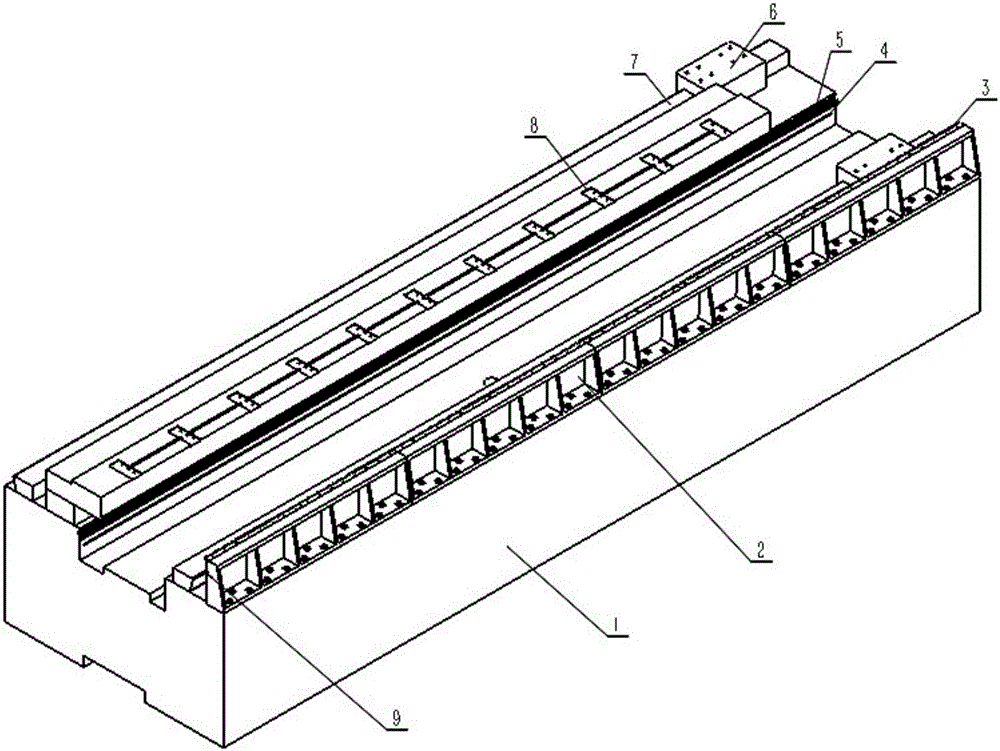

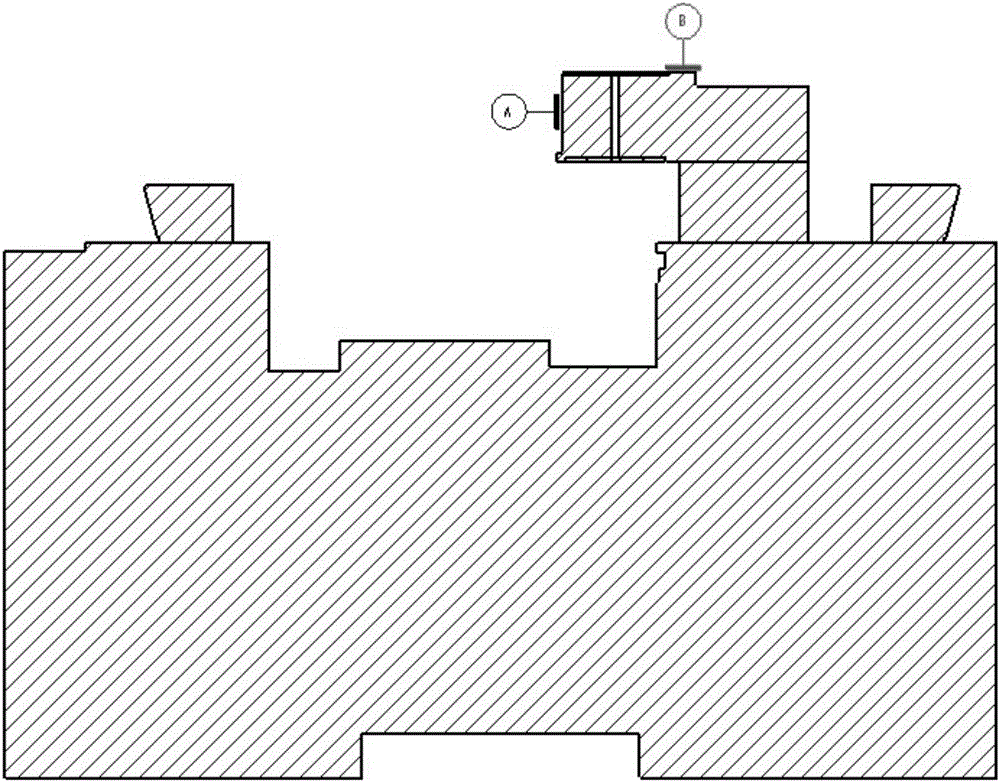

[0053] combine figure 1 and figure 2 , an automatic measurement device for the dimensional accuracy of a rolling linear guideway, including a bed platform I, a clamping device II, a gantry III, a measuring platform IV, a Y-axis feed part V, a Z-axis feed part VI and a grating assembly VII, wherein The measured guide rail IX is placed on the bed platform Ⅰ. During the measurement, it is fixed and centered on the workbench 8 by the clamping device Ⅱ. A pair of parallel air-floating guide rail pairs 6 and 7 are set above the bed component Ⅰ. Realize the linear movement of the gantry III and the measuring platform IV along the direction of the measured guide rail Ⅸ (that is, the Z-axis direction). The gantry III is fixed on the air bearing slider 6, and the Y-axis feed is set on the inner side of the gantry III. Part Ⅴ, and the Z-axis feeding part Ⅵ is set on the opposite side, and the Y-axis feeding part Ⅴ is connected to the measuring platform Ⅳ through the adapter plate 37, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com