LM correction method for identification of heat conductivity changing along with temperature

A thermal conductivity, temperature-dependent technology, applied in the field of thermal conductivity identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

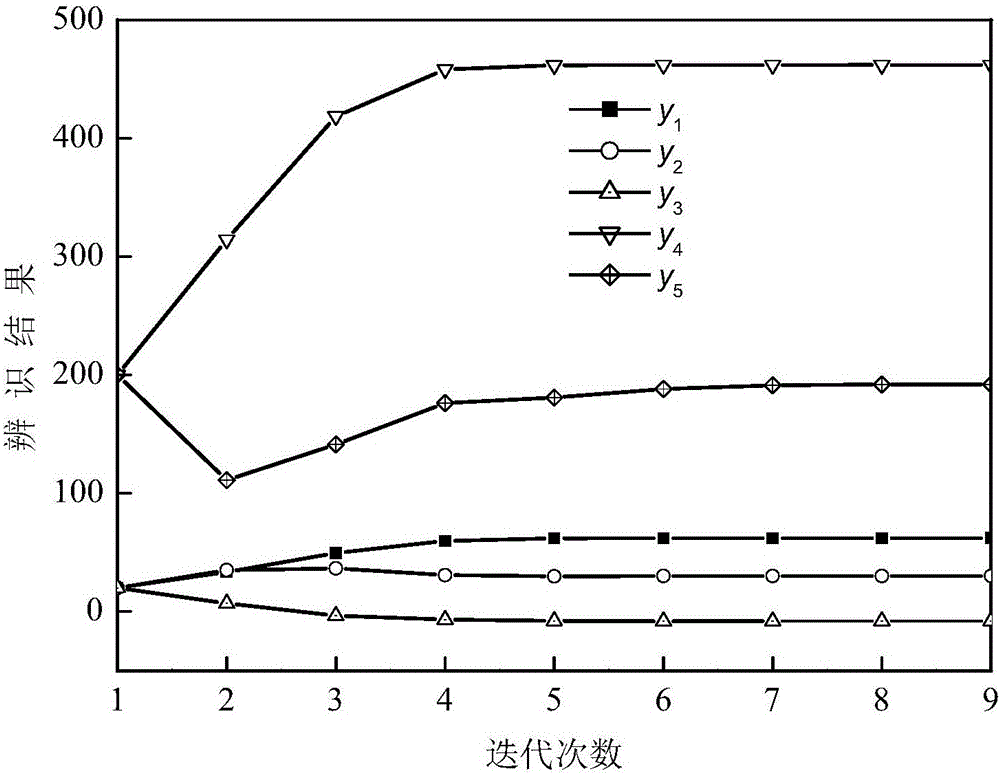

Embodiment 1

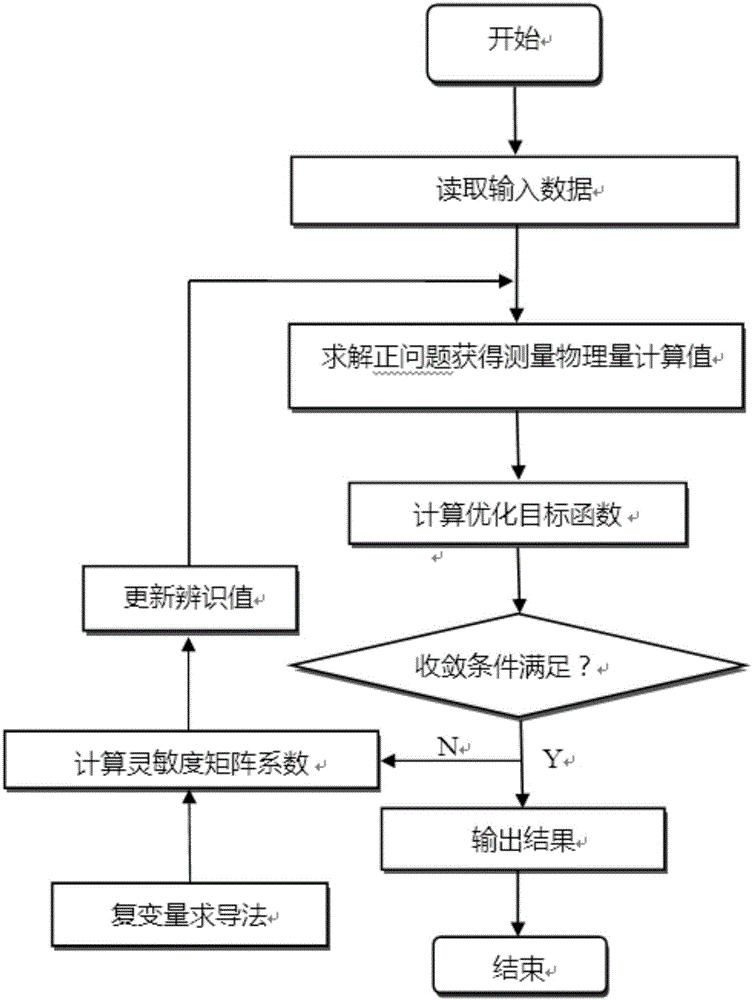

[0036] In Example 1, the thermal conductivity as a function of temperature has a functional form, so only constant coefficients in the functional form are identified. according to figure 1 The steps shown are calculated as follows:

[0037] S1: Read the input data from the input file, including the temperature information of the measuring point, geometric conditions, initial conditions, boundary conditions and the imaginary initial value of each coefficient in the functional form of thermal conductivity y=(y 1 ,y 2 ,...,y N );

[0038] S2: By inputting data, solve the transient nonlinear heat conduction forward problem, and obtain the calculated value t(y) of the measuring point temperature;

[0039] S3: Calculate the optimization objective function:

[0040] S ( y ) = Σ i = 1 M ( ...

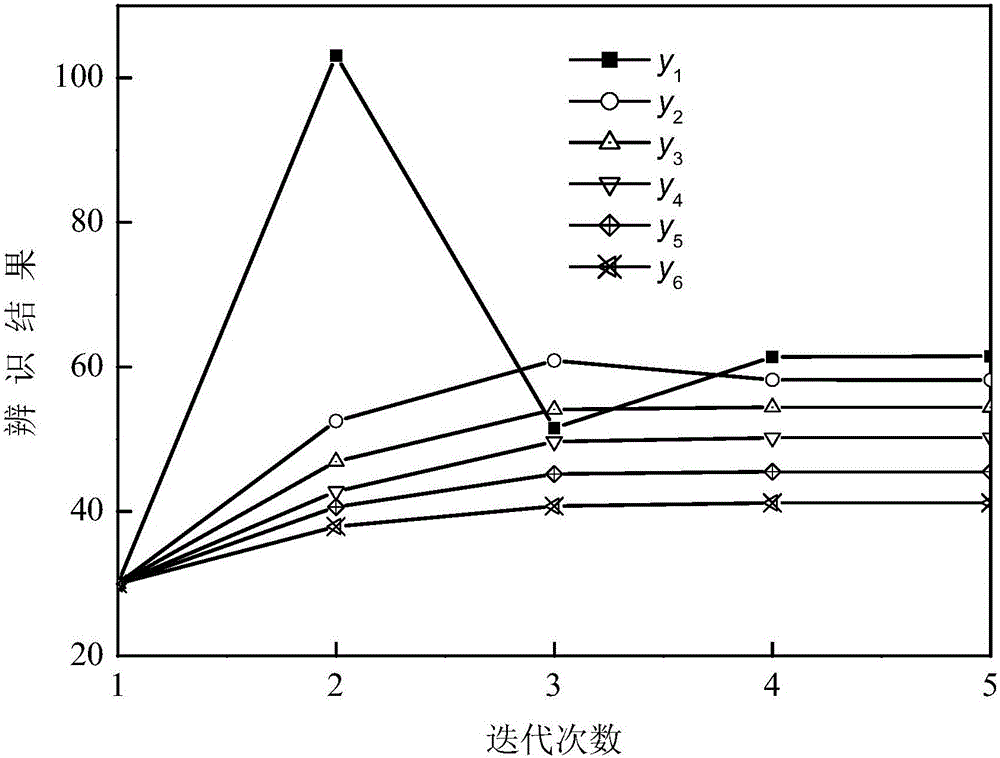

Embodiment 2

[0053] In Example 2, the thermal conductivity as a function of temperature does not have a functional form, therefore, the thermal conductivity at a specified temperature is identified. according to figure 1 The steps shown are calculated as follows:

[0054] S1: Read the input data from the input file, including the temperature information of the measuring point, geometric conditions, initial conditions, boundary conditions and the hypothetical initial value of the thermal conductivity at the specified temperature y=(y 1 ,y 2 ,...,y N );

[0055] S2: By inputting data, solve the transient nonlinear heat conduction forward problem, and obtain the calculated value t(y) of the measuring point temperature. It should be noted that the thermal conductivity at other temperatures is given by y=(y 1 ,y 2 ,...,y N ) is characterized by linear interpolation;

[0056] S3: Calculate the optimization objective function:

[0057] S ( y ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com