Detection method for deep layer impurity element

A technology of impurity elements and detection methods, which is applied in the direction of measuring devices, electrical components, semiconductor/solid-state device testing/measurement, etc., can solve the problems that affect the detection accuracy, blockage of sampling cones, and inability to perform, so as to achieve accurate and reliable detection results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

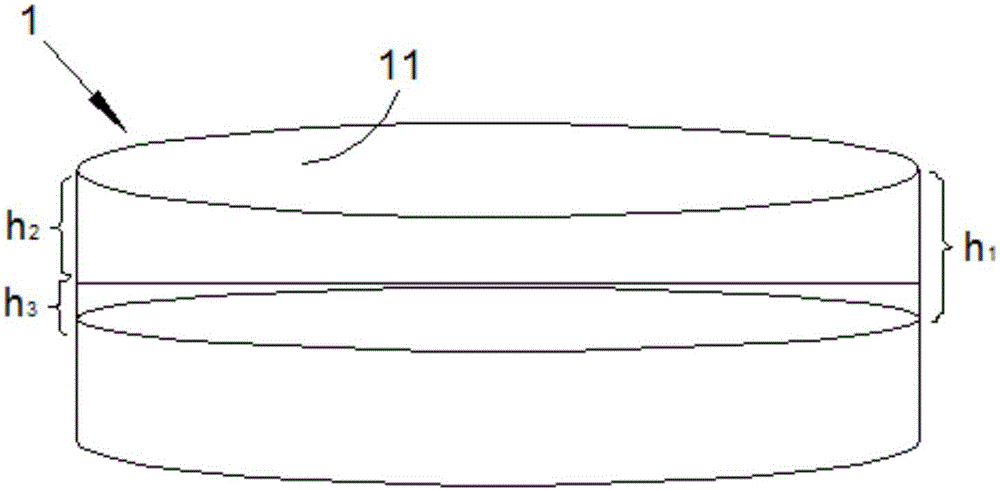

[0022] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0023] As we all know, impurity element pollution, especially metal impurity pollution, has a great impact on the performance of semiconductor devices. The level of metal impurity pollution directly determines the white pixel level of CMOS image sensor (CMOS Image Sensor, CIS) products, and ultimately affects the photo effect. Obviously, the monitoring of metal impurity contamination is particularly important in the manufacture of semiconductor devices.

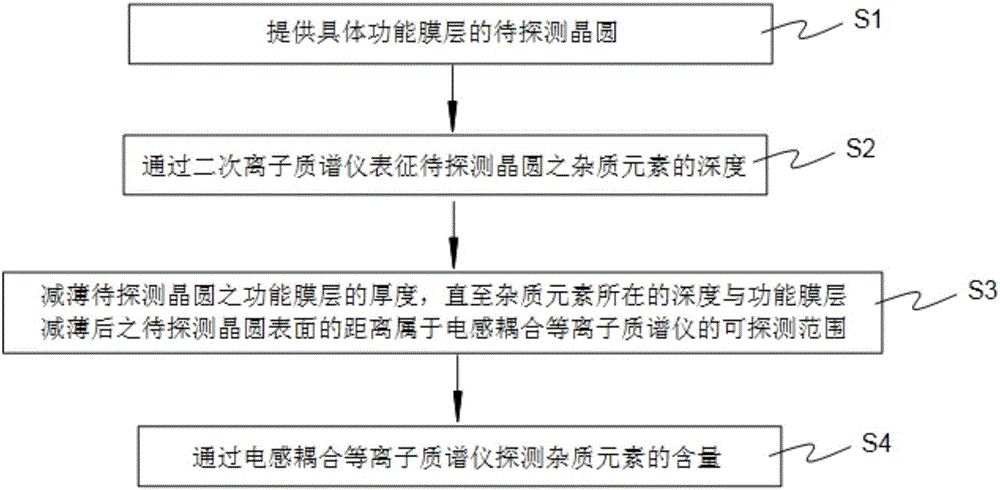

[0024] At present, the industry's monitoring of metal impurity contamination is limited to the use of inductively coupled plasma mass spectrometry (ICP-MS), which has its own inherent defects. For example, the detection of impurity elements in shallow layers is more accurate, but the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com